Corrugated steel plate lining reinforcement parameter optimization design method and structure based on tunnel lining defect detection

A corrugated steel plate, optimized design technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of increased corrugated steel plate specifications, high subjectivity, and inability to fully guarantee the accuracy of relevant parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

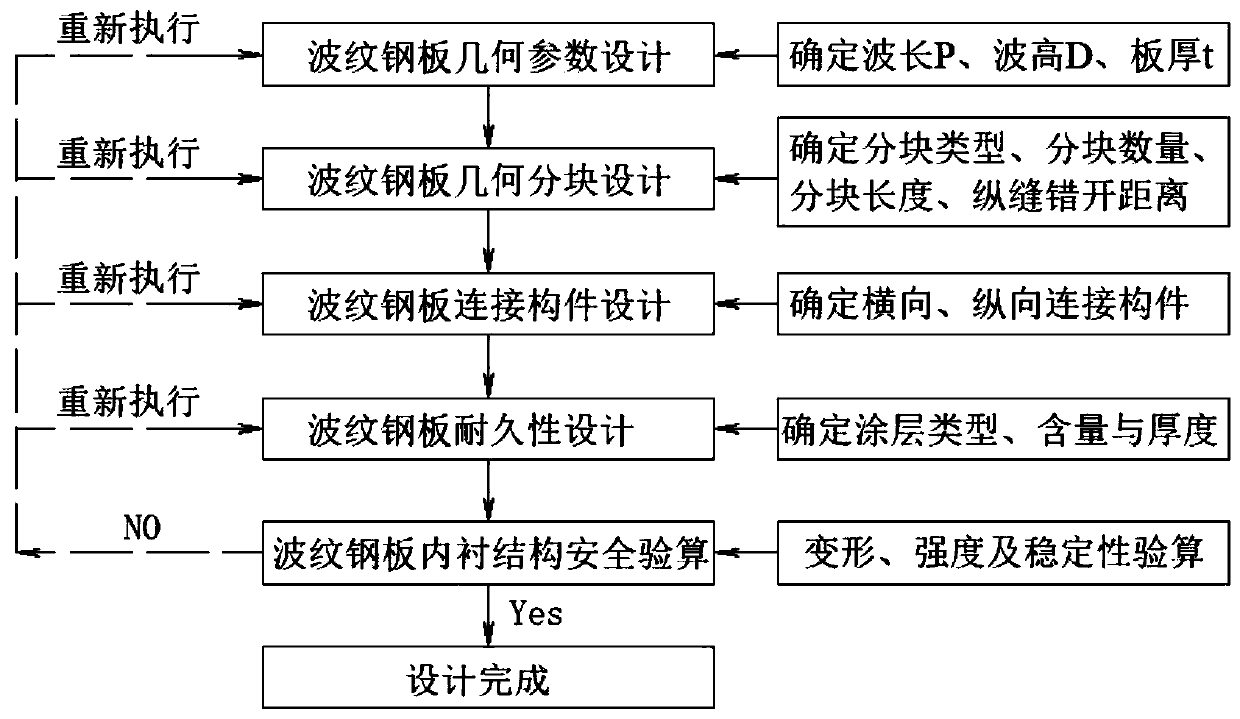

[0070] see Figure 1 to Figure 5 , an optimal design method for corrugated steel lining reinforcement parameters based on tunnel lining defect detection, including the following steps:

[0071] S1: The geometric parameter design of the corrugated steel plate 3, determine the three parameters of the corrugated steel plate 3 wavelength P, wave height D, and plate thickness t;

[0072] S11: According to the results of on-site inspection and investigation, obtain the non-destructive testing secondary lining 1 thickness table of the damaged section of the tunnel, and compare the current evaluation standards to determine the lining defects and disease levels (slight, serious, serious, and extremely serious). If the level of lining damage is extremely serious, use corrugated steel plate 3 lining reinforcement parameter measures to deal with it, otherwise use other measures to deal with it.

[0073] S12: Select the most unfavorable section according to the non-destructive testing sec...

Embodiment 2

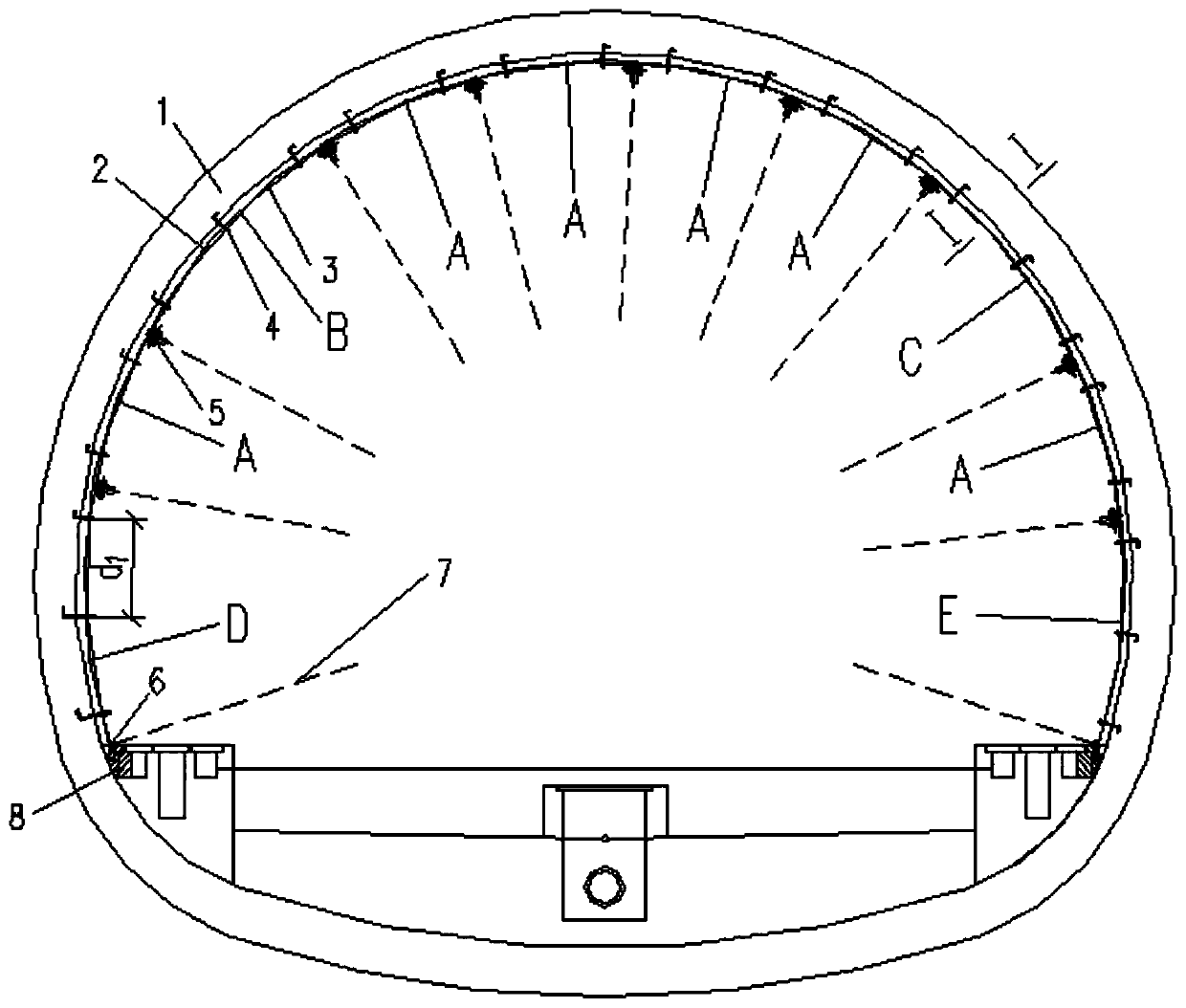

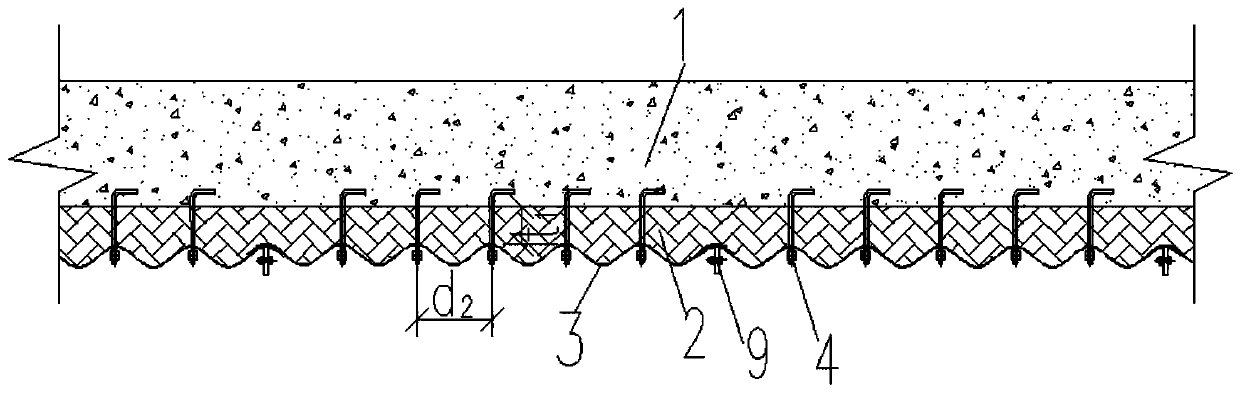

[0117]The present invention provides a corrugated steel lining reinforcement structure based on tunnel lining defects, which includes several corrugated steel plates 3, and several corrugated steel plates 3 are connected by corrugated steel plate transverse splicing members 5 and corrugated steel plate longitudinal connecting members 9 to form a tunnel secondary lining Corrugated steel lining in contour shape, the corrugated steel lining is fixedly connected with the tunnel secondary lining 1 through the transverse connecting anchor bolt 4, one end of the transverse connecting anchor bolt is pre-embedded and fixed in the tunnel secondary lining, the transverse The other end of the connecting anchor passes through the filling layer 2 and the corrugated depression on the outer corrugated surface of the corrugated steel plate and is connected with the nut. The centerline of the transverse connection anchor is located at the center of the corrugation depression. The arch feet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com