Negative plate, preparation method thereof and lithium ion battery

A technology of negative electrode sheet and negative electrode, which is applied in the field of its preparation, lithium-ion battery, and negative electrode sheet, can solve the problems of ultra-thin current collectors that are easy to wrinkle, avoid the potential risk of battery lithium analysis, improve production efficiency, prevent wrinkling and The effect of staying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 provides a negative electrode sheet, and the edge of the negative electrode sheet has high rigidity.

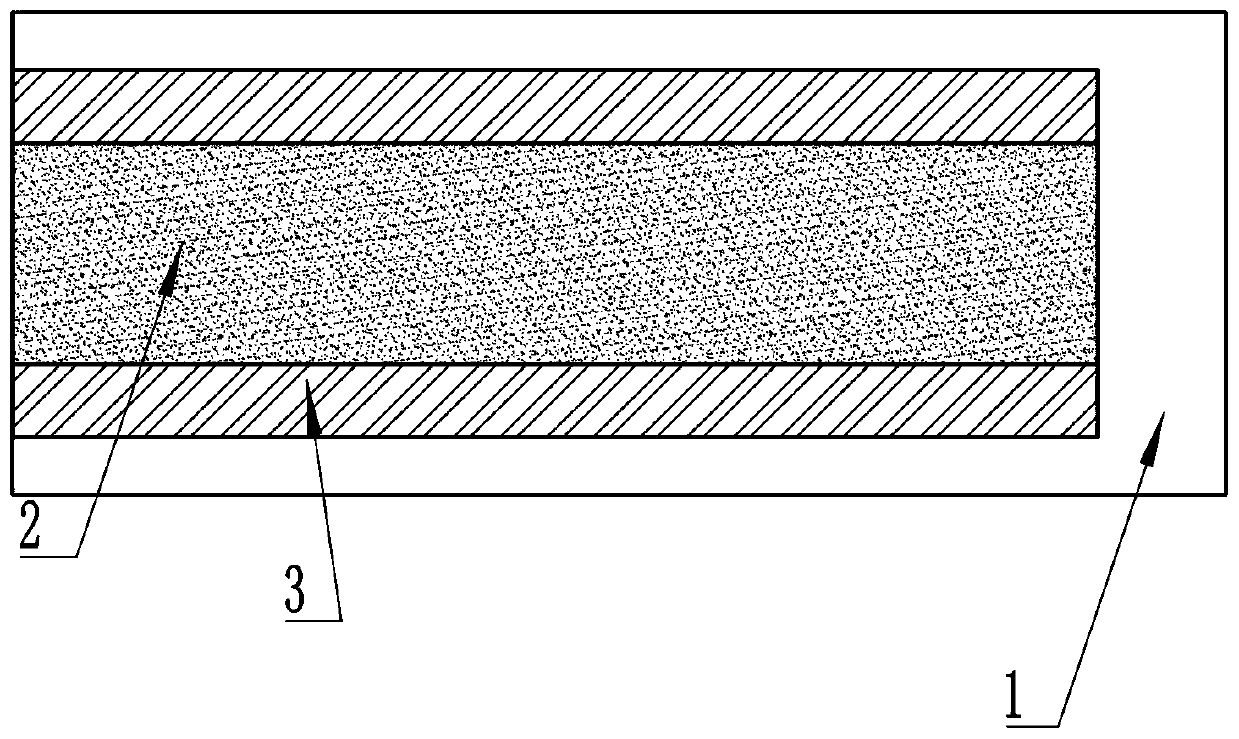

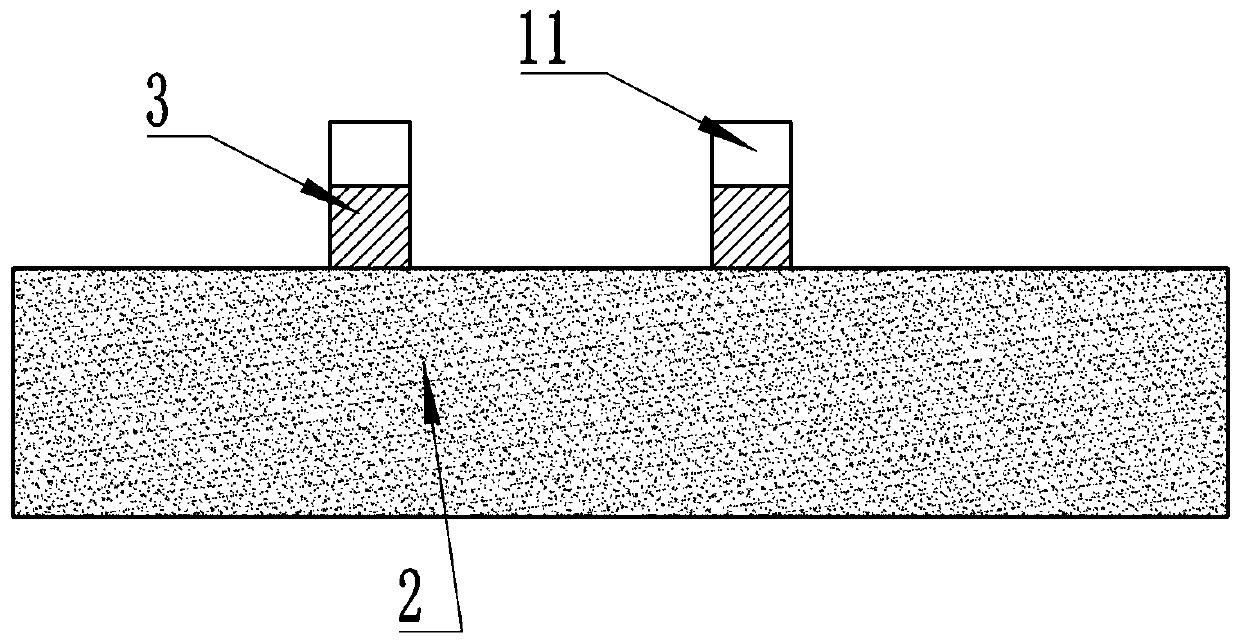

[0037] Please refer to figure 1 , the negative electrode sheet includes a negative electrode current collector 1, the negative electrode current collector 1 is coated with negative electrode slurry to form a negative electrode coating film area 2, at least one side edge of the negative electrode film area 2 is coated with insulating slurry to form an insulating coating film area 3, The insulating coating film region 3 and the negative electrode coating film region 2 are adjacent to or partially soluble in each other.

[0038] The edge of the insulating coating area 3 away from the negative electrode coating area 2 leaves a negative electrode blank area for forming the negative electrode tab 11 , and the insulating coating film area 3 is located at the root of the negative electrode tab 11 .

[0039] In the negative electrode sheet provided by the embodime...

Embodiment 2

[0050] The embodiment of the present invention provides a method for preparing the negative electrode sheet, which is used to prepare the negative electrode sheet described in the first embodiment.

[0051] The preparation method comprises the following steps:

[0052] Coating the negative electrode slurry on the negative electrode current collector 1 to form a negative electrode coating area 2, and coating the insulating slurry on at least one side edge of the negative electrode coating area 2 to form an insulating coating film area 3;

[0053] The negative electrode slurry and the insulating slurry are dried by baking, and after drying, the insulating coating film area 3 and the negative electrode coating film area 2 are adjacent to or partially soluble in each other to obtain a negative electrode sheet;

[0054] Wherein, a negative electrode blank area for forming the negative electrode tab 11 is left on the edge of the side of the insulating coating film region 3 away from...

Embodiment 3

[0064] Embodiment 3 provides a lithium-ion battery and its preparation method. The lithium-ion battery includes the negative electrode sheet described in Embodiment 1 and the negative electrode sheet prepared by the preparation method described in Embodiment 2.

[0065] The lithium-ion battery includes a battery core, and the battery core is filled with electrolyte. The battery core includes a positive electrode sheet, a separator and a negative electrode sheet stacked in sequence.

[0066] The positive electrode sheet includes a positive electrode current collector, and the positive electrode slurry is coated on the positive electrode current collector to form a positive electrode coating film area. The positive electrode current collector is preferably aluminum foil.

[0067] The positive electrode slurry includes the following components in parts by mass: 96 parts of positive electrode material, 3 parts of positive electrode conductive agent, 1 part of third binder and 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com