Lithium metal with rigid-elastic interface layer as well as preparation method and application of lithium metal

An interface layer, lithium metal technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effect of inhibiting lithium dendrites, high mechanical strength, fast and stable deposition/stripping behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

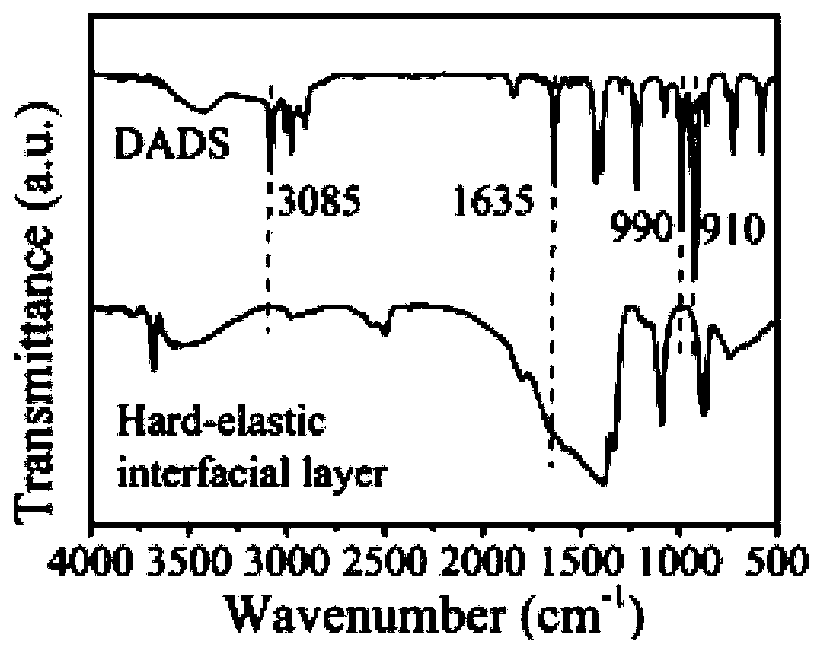

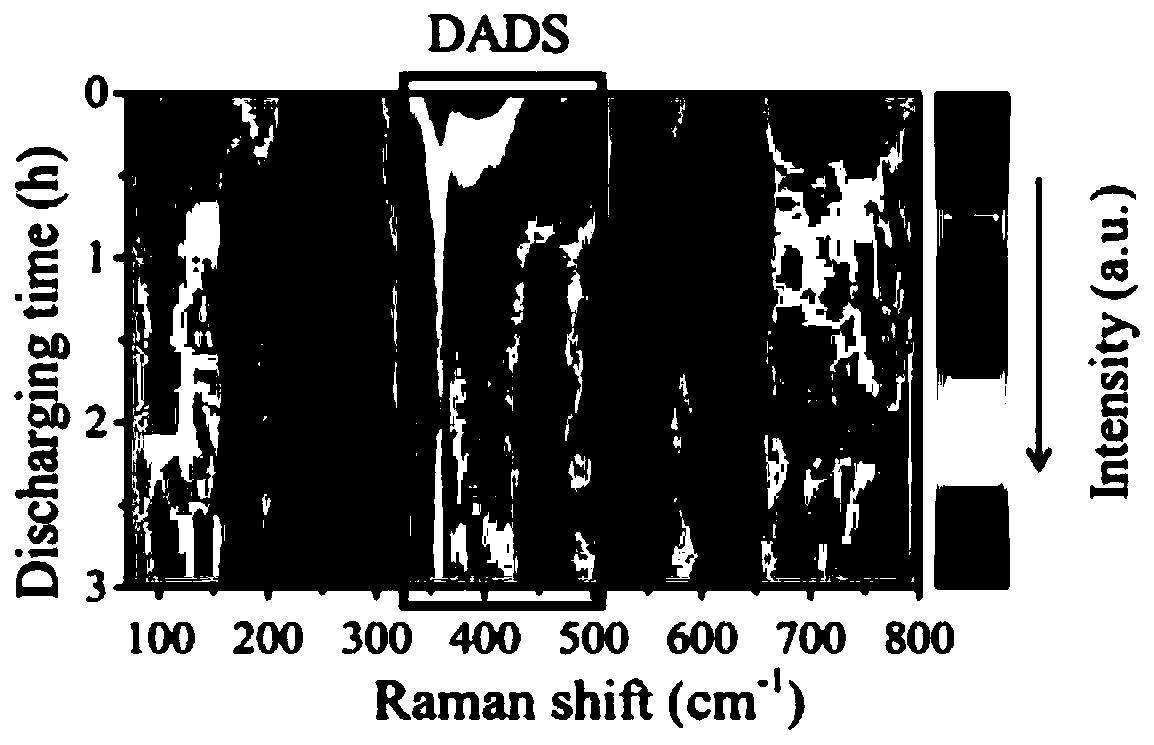

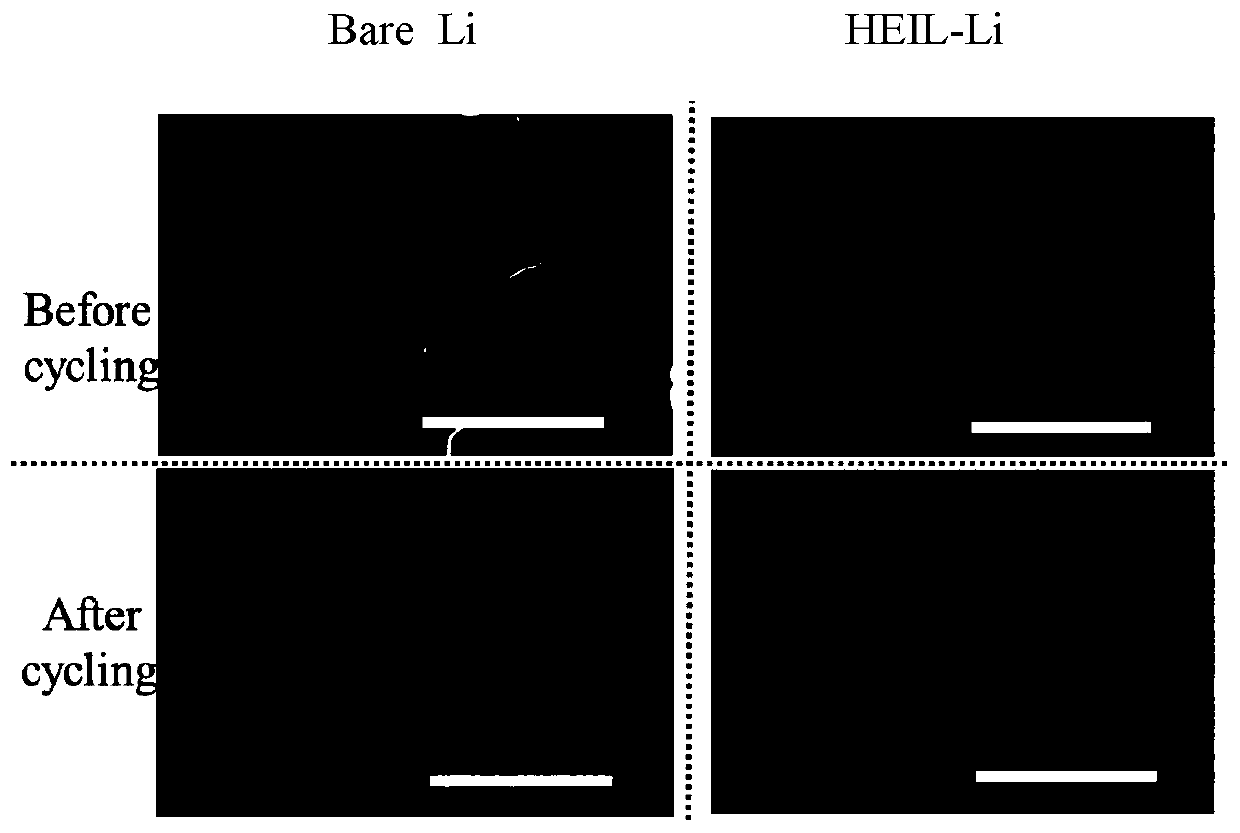

[0033] A preparation method of lithium metal with a rigid-elastic interfacial layer, comprising the following steps:

[0034] Step 1. Mix LiTFSI and DOL / DME with a volume ratio of 1:1 so that the concentration of LiTFSI is 1mol / L, then add 10mg DADS to the 190mg mixed solution to prepare solution A;

[0035] Step 2. Put ordinary lithium metal, diaphragm, ordinary lithium metal, gasket, shrapnel, and negative electrode shell on the positive shell of the button battery in sequence, and add 30 μL of solution A obtained in step 1 as electrolyte to the battery, and put it in the glove Assembled into a button-type symmetrical battery in the box;

[0036] Step 3. For the button cell obtained in step 2, at 1mAcm -2 The lithium metal with the rigid-elastic interface layer can be obtained by charging under current for 5 hours for deposition. After the deposition, the battery is disassembled, the lithium electrode is taken out, and washed repeatedly with DOL.

Embodiment 2

[0038] Lithium metal with a rigid-elastic interface layer was prepared according to the preparation method of Example 1, only the deposition time in step 3 was adjusted to 10 h, and other steps were kept unchanged.

Embodiment 3

[0040]Lithium metal with a rigid-elastic interface layer was prepared according to the preparation method of Example 1, only the deposition time in step 3 was adjusted to 15 h, and other steps were kept unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com