Oxygen reduction catalyst as well as preparation method and application thereof

A catalyst and thermal cracking technology, which is applied in the field of oxygen reduction catalyst and its preparation, can solve the problems of high price of oxygen reduction catalyst and waste tire pollution, and achieve excellent catalytic performance, easy operation and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of an oxygen reduction catalyst, comprising the steps of:

[0028] Take waste tire pyrolysis carbon black, and carry out thermal cracking at 700°C for 2 hours in an ammonia atmosphere;

[0029] Cool the waste tire pyrolysis carbon black after primary pyrolysis to room temperature, then place it in 0.3 mol / L sulfuric acid aqueous solution, stir at 100°C for 8 hours, filter, wash the filter cake with water and ethanol in sequence until the pH of the washing liquid is Neutral, then bake at 100°C for 24 hours;

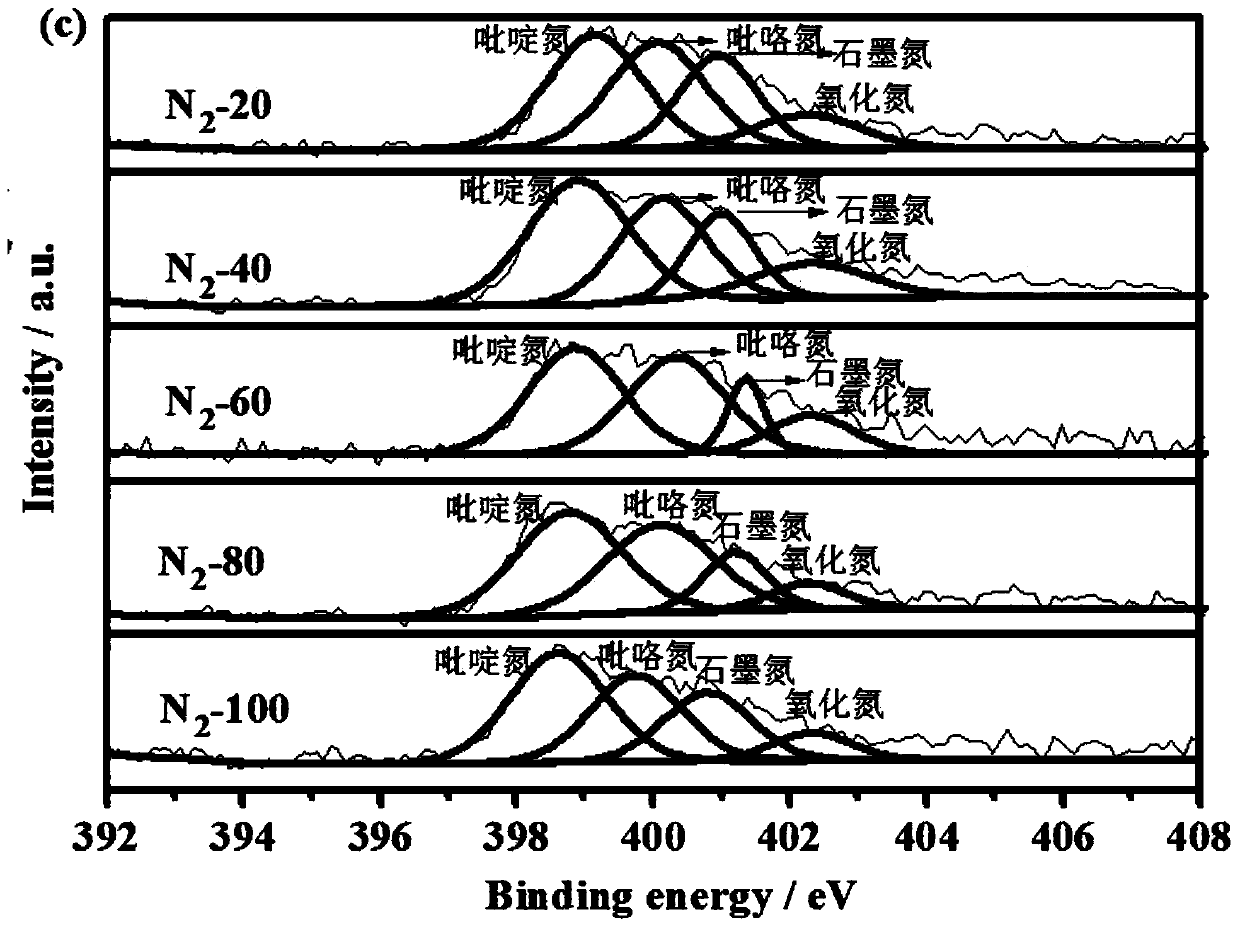

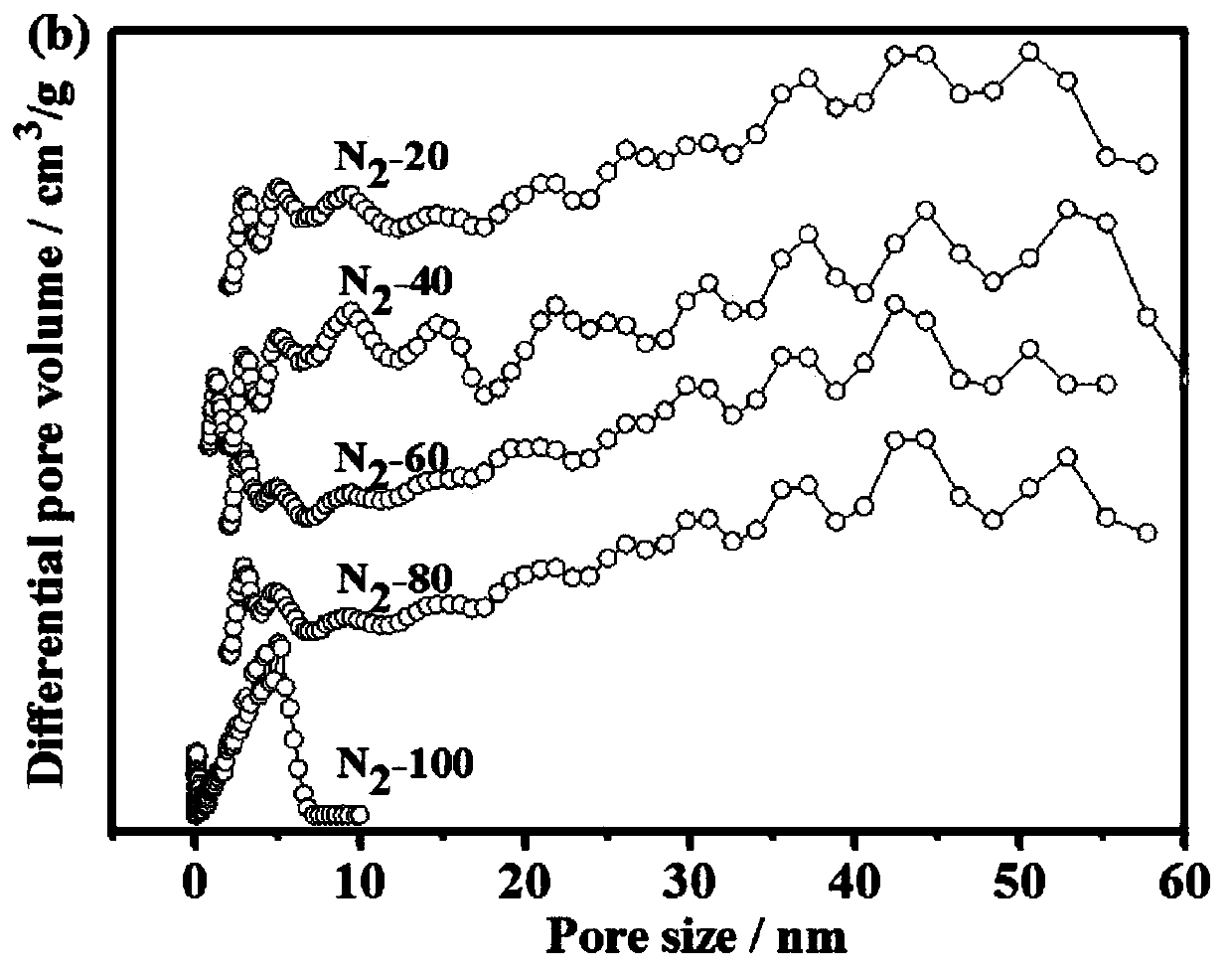

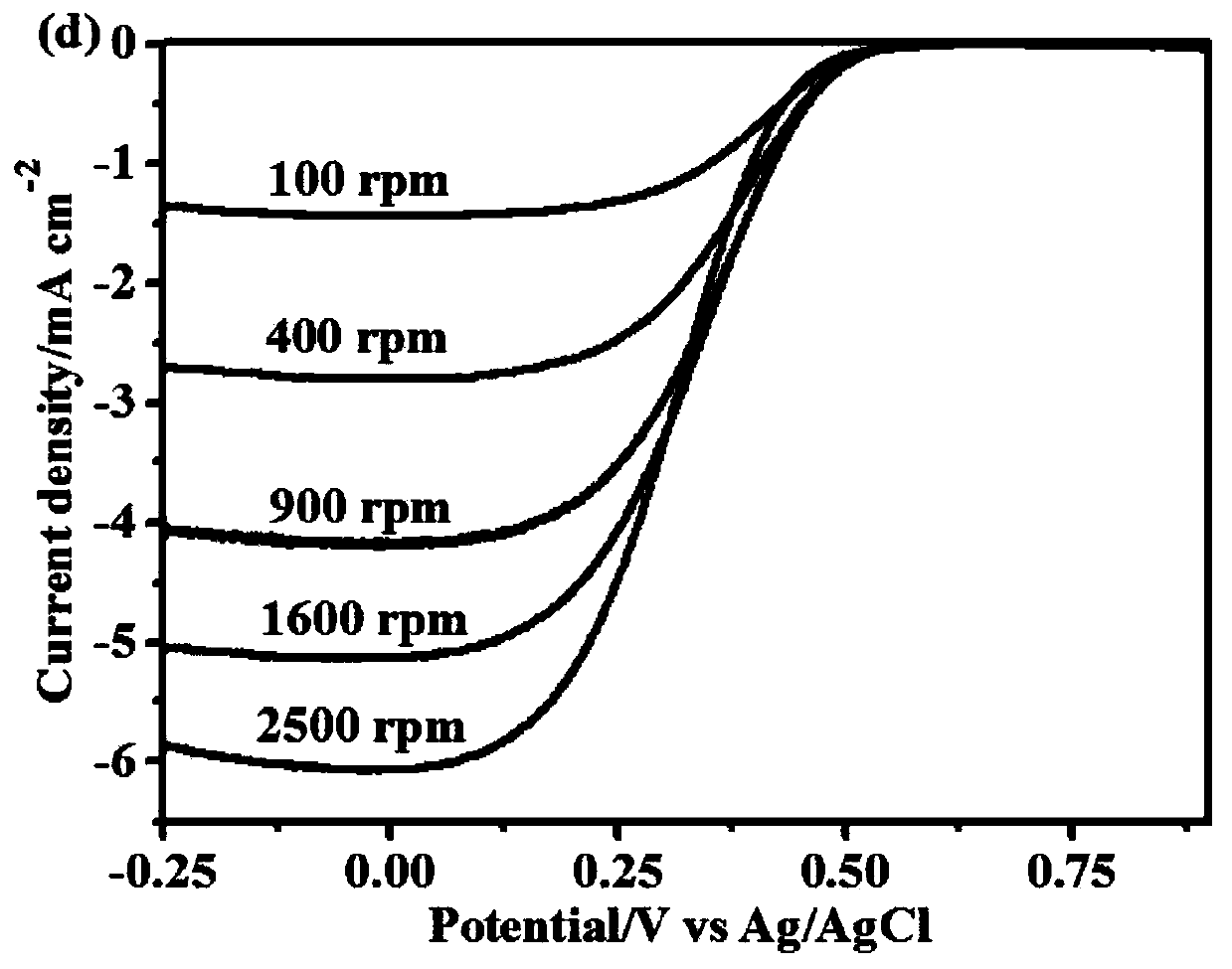

[0030] Then, in a mixed gas atmosphere of nitrogen and ammonia, carry out secondary thermal cracking at 1100° C. for 0.5 h, and cool to room temperature to obtain an oxygen reduction catalyst, wherein the volume fraction of nitrogen in the mixed gas is 20%, and N 2 -20 means.

Embodiment 2

[0032] A preparation method of an oxygen reduction catalyst, comprising the steps of:

[0033] Take waste tire pyrolysis carbon black, and carry out thermal cracking at 1000°C for 20 minutes in an ammonia atmosphere;

[0034] Cool the waste tire pyrolysis carbon black after primary pyrolysis to room temperature, then place it in a 1mol / L sulfuric acid aqueous solution, stir at 80°C for 24 hours, filter, wash the filter cake with water and ethanol in sequence, until the pH of the washing solution is neutral properties, and then baked at 60°C for 36h;

[0035] Then, in a mixed gas atmosphere of nitrogen and ammonia, carry out secondary thermal cracking at 850° C. for 2 h, cool to room temperature to obtain an oxygen reduction catalyst, wherein the volume fraction of nitrogen in the mixed gas is 40%, and use N 2 -40 means.

Embodiment 3

[0037] A preparation method of an oxygen reduction catalyst, comprising the steps of:

[0038] Take waste tire pyrolysis carbon black, and carry out thermal cracking at 950°C for 1 hour in an ammonia atmosphere;

[0039] Cool the waste tire pyrolysis carbon black after primary thermal cracking to room temperature, then place it in a 0.5 mol / L sulfuric acid aqueous solution, stir at 100°C for 8 hours, remove unstable impurities, filter, and wash with water and ethanol successively Filter cake, until the pH of the washing solution is 7, then bake at 100°C for 24 hours;

[0040] Then, in a mixed gas atmosphere of nitrogen and ammonia, carry out secondary thermal cracking at 900° C. for 2 h, cool to room temperature to obtain an oxygen reduction catalyst, wherein the volume fraction of nitrogen in the mixed gas is 20%, and use N 2 -20 means.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com