A kind of dairy cow production performance measurement standard substance and its preparation method and application

A technology of production performance and reference material, applied in biological testing, other equipment, applications, etc., can solve the problems of increased confidence interval of calibration linear regression curve, narrow component concentration range, high leverage value, and achieve increased consistency and measurement level. Improved, more accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The design of embodiment 1DHI standard substance

[0056] The present embodiment provides a kind of dairy cow production performance determination (DHI) standard substance, comprising:

[0057] The mass percent range of fat is 0.20%-6.00%, and 12 level gradients are designed; the mass percent range of protein is 2.00%-4.50%, and 6 level gradients are designed; the mass percent range of lactose is 4.00%-5.00%, and 4 levels are designed A horizontal gradient, according to the composition of the above-mentioned mass percentage range and the corresponding horizontal gradient, DHI standard substance is obtained through orthogonal design, and the DHI standard substance includes standard substance 1-12, as shown in Table 1 below:

[0058] Table 1 DHI standard substance

[0059]

Embodiment 2

[0060] The deployment of embodiment 2 DHI standard substance

[0061] 1. Deployment method

[0062] The raw materials (cream, skimmed milk, membrane retentate and membrane filtrate) obtained by the pre-experiment were determined by FOSS milk component analyzer and chemical determination method to determine the content of fat, protein and lactose respectively. In addition, add pure water and analytical pure lactose as raw materials, input into the EXCEL form; use its planning and solving function to calculate the amount of raw materials for each standard product, and then carry out formula deployment; determine the chemical composition of the product by chemical determination, and investigate its difference with the standard product degree of compliance. Table 2 below is an example of the preparation of Standard 1.

[0063] Table 2 Standard product 1 deployment table

[0064]

[0065]

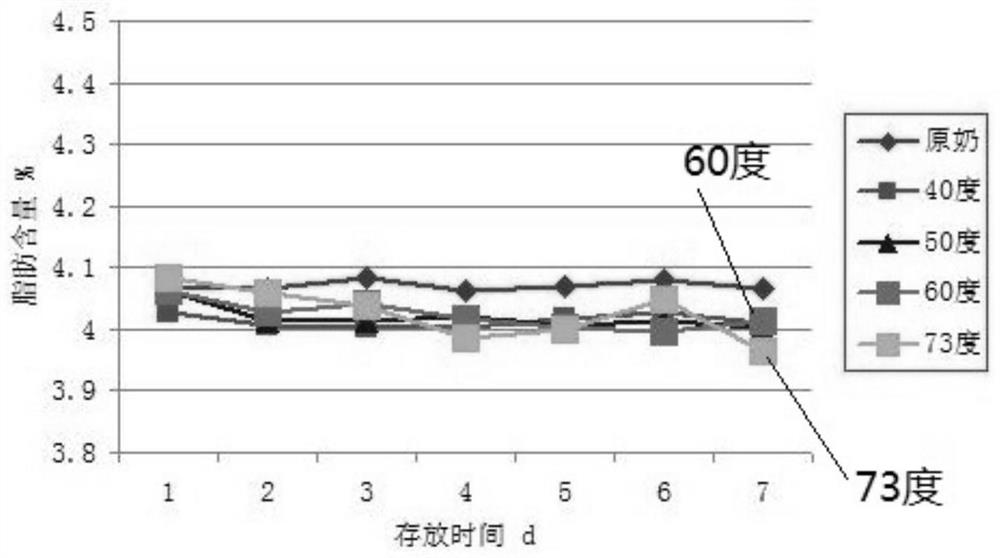

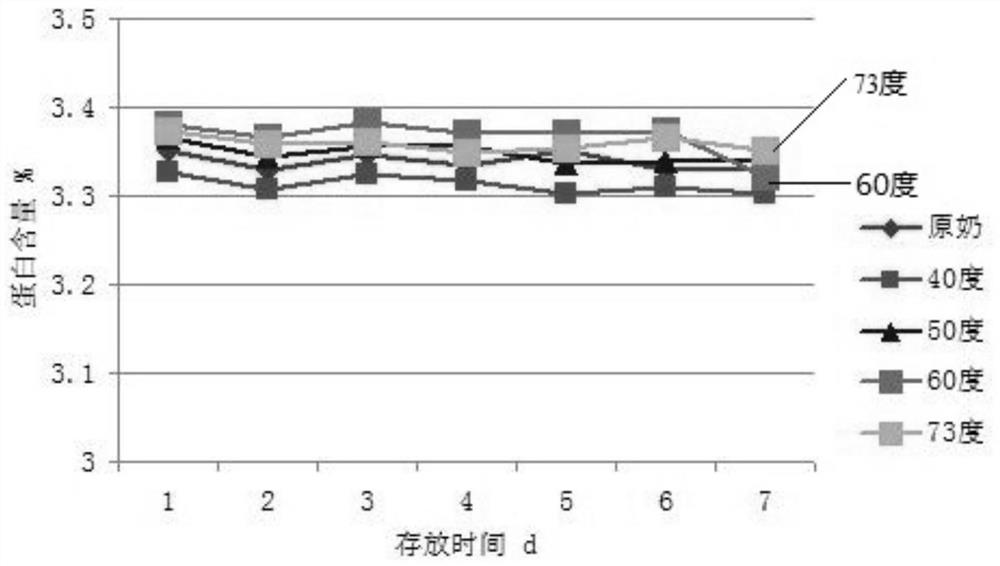

[0066] 2. Inspection of the prepared DHI standard substance

[0067] Send the prod...

Embodiment 3

[0079] The preparation of embodiment 3 DHI standard substance

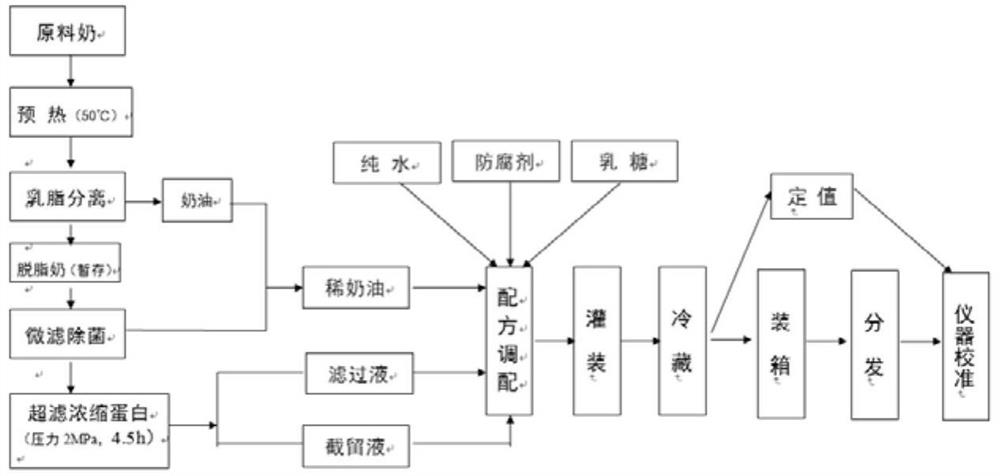

[0080] The present embodiment provides a kind of preparation method for preparing DHI standard substance, comprises the following steps:

[0081] (1) Sterilize the tubular sterilizer with hot water above 95°C, then take raw milk and add it to the tubular sterilizer for heat treatment, the heat treatment temperature is 50°C, and the treatment time is 18s;

[0082] (2) The heat-treated raw milk is directly added to a milk fat separator for skimming treatment, and the obtained skimmed milk and milk fat are respectively put into different storage tanks for subsequent use;

[0083](3) Carry out microfiltration sterilization to skimmed milk, filter equipment adopts PALL ceramic membrane filtration equipment, filter membrane selects the ceramic membrane column of 1.4 micron order, described ceramic membrane column is installed to PALL ceramic membrane filtration equipment, with not more than 8 Heat up at a rate of ℃ / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com