Transformer substation porcelain bottle charged automatic cleaning robot cleaner

A technology of automatic cleaning and robotics, applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of reducing work efficiency, increasing labor intensity of electric workers, and low efficiency of cleaning methods, etc., to achieve Good cleaning effect and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

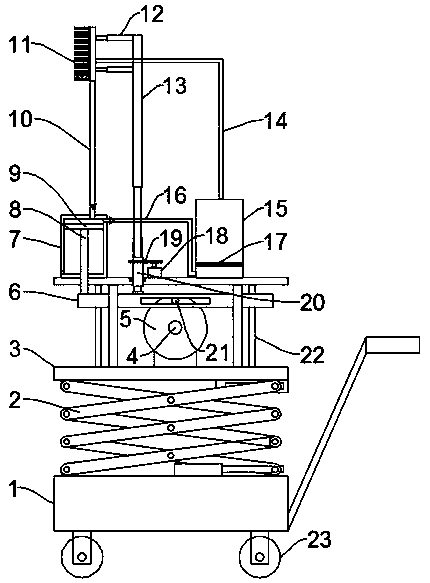

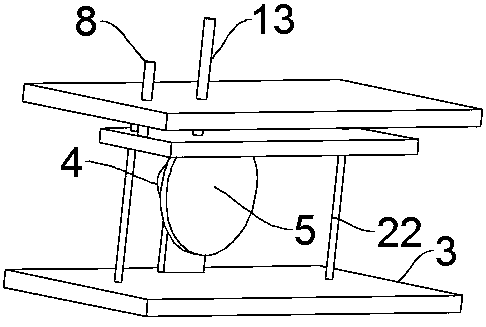

[0023] see Figure 1~2 , in an embodiment of the present invention, a live automatic cleaning robot cleaner for ceramic bottles in substations, including a frame 1 and a cleaning assembly, the bottom of the frame 1 is evenly and symmetrically equipped with rollers 23, and the rollers 23 are self-locking rollers, which are convenient The movement of the device, the cleaning assembly is installed on the frame 1, the cleaning assembly includes a mounting plate 3, a brush plate 11, a drive mechanism and a dust removal mechanism for driving the brush plate 11 to reciprocate up and down, the mounting plate 3 Installed above the frame 1, in this embodiment, a scissor lifting mechanism 2 is connected between the mounting plate 3 and the frame 1 for adjusting the height of the mounting plate 3, and a brush plate 11 is provided above the mounting plate 3 And a drive mechanism for driving the brush plate 11 to reciprocate up and down. The brush plate 11 is vertically installed on the top...

Embodiment 2

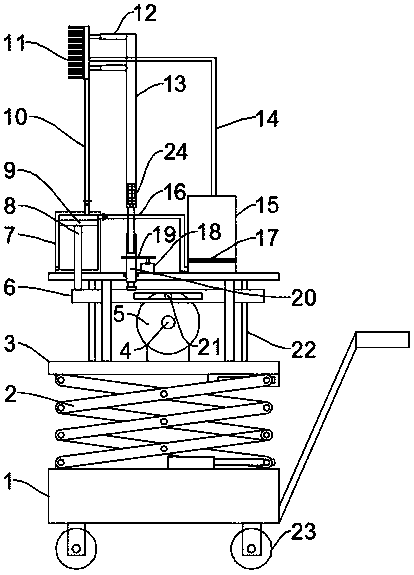

[0027] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that, in order to facilitate manual operation, the installation rod 13 includes two connecting rods that are socketed, and the two connecting rods are connected by bolts, and a brush plate is installed. The bottom end of the connecting rod of 11 is provided with a grip cover 24, which is convenient for the staff to manually clean some positions.

[0028] The working principle of the present invention is: when the present invention is in use, start the first motor 4, the first motor 4 drives the turntable 5 to rotate, the turntable 5 drives the pin shaft 21 to rotate, the pin shaft 21 drives the movable plate 6 to move up and down, and the movable plate 6 drives The installation rod 13 and the piston rod 8 move up and down, the installation rod 13 drives the brush plate 11 to move up and down, and repeatedly brushes. Spray from the connecting nozzle on the surface of the brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com