A preparation method of bamboo powder reinforced laminated veneer lumber for doors

A technology of laminated veneer and bamboo powder, which is applied in the joining of wooden veneers, manufacturing tools, wood impregnation, etc., can solve the problems of reducing the strength of laminated veneer, and achieve the improvement of internal bonding strength and continuous improvement. the effect of enhancing the resistance to blisters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

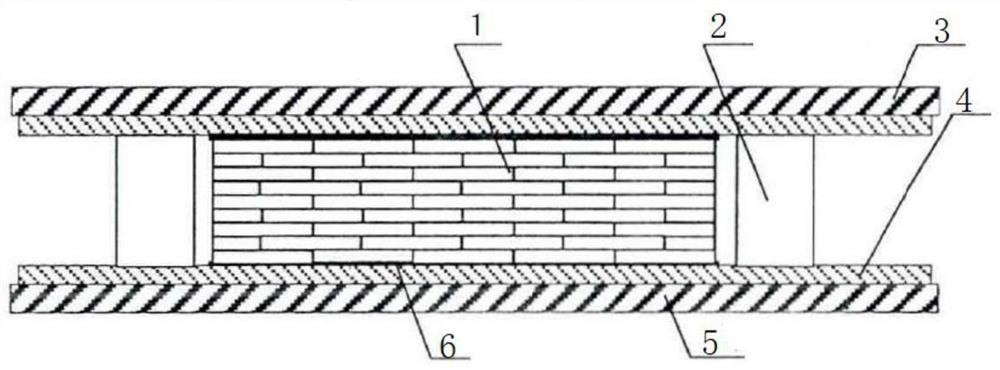

Image

Examples

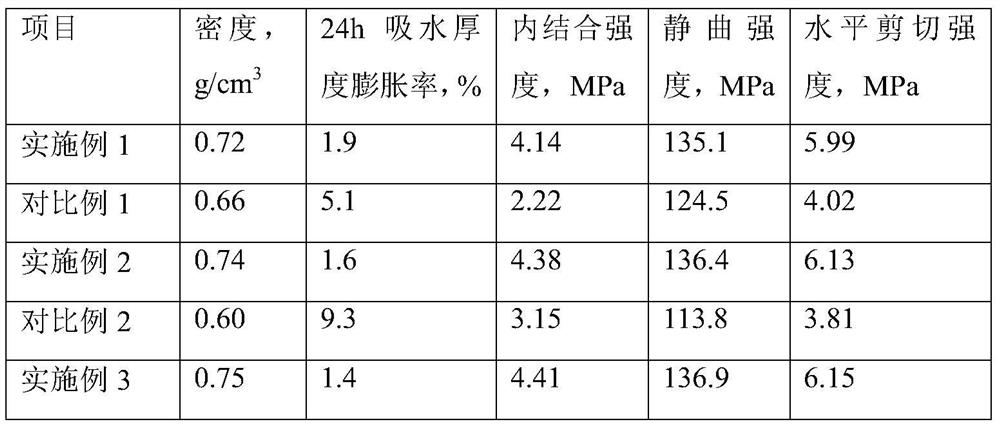

Embodiment 1

[0026] A preparation method of bamboo powder reinforced laminated veneer lumber for doors, comprising the following steps:

[0027] (1) Modification of bamboo powder

[0028] Bamboo powder, aluminum sol, alumina powder are added in the mixer according to the mass ratio of 30:7:20 after stirring at a high speed of 600r / min for 30min, obtain modified bamboo powder, the average particle size of bamboo powder is 50 orders, The average particle size of alumina is 100 mesh, and the solid content of aluminum sol is 15%;

[0029] (2) Preparation of solid wood impregnation solution

[0030] After mixing and stirring the urea-formaldehyde resin adhesive and disodium sebacate according to the ratio of 10:1 in mass ratio, a solid wood impregnating solution is obtained, wherein the solid content of the urea-formaldehyde resin adhesive is 18%;

[0031] (3) Solid wood dipped in glue

[0032] Add the solid wood impregnation solution into the impregnation treatment tank, then place the soli...

Embodiment 2

[0036] A preparation method of bamboo powder reinforced laminated veneer lumber for doors, comprising the following steps:

[0037] (1) Modification of bamboo powder

[0038] Bamboo powder, aluminum sol, aluminum oxide powder are added in the mixer according to the mass ratio of 35:7:20 after 35min with the rotating speed of 650r / min high-speed stirring, obtain modified bamboo powder, the average particle size of bamboo powder is 55 orders, The average particle size of alumina is 130 mesh, and the solid content of aluminum sol is 18%;

[0039] (2) Preparation of solid wood impregnation solution

[0040] After mixing and stirring the urea-formaldehyde resin adhesive and disodium sebacate according to the ratio of 13:1 in mass ratio, a solid wood impregnating solution is obtained, wherein the solid content of the urea-formaldehyde resin adhesive is 20%;

[0041] (3) Solid wood dipped in glue

[0042] Add the solid wood impregnation solution into the impregnation treatment tan...

Embodiment 3

[0046] A preparation method of bamboo powder reinforced laminated veneer lumber for doors, comprising the following steps:

[0047] (1) Modification of bamboo powder

[0048] Bamboo powder, aluminum sol, aluminum oxide powder are added in the mixer according to the mass ratio of 40:7:20 after stirring at a high speed of 700r / min for 40min, obtain modified bamboo powder, the average particle size of bamboo powder is 60 orders, The average particle size of alumina is 150 mesh, and the solid content of aluminum sol is 20%;

[0049] (2) Preparation of solid wood impregnation solution

[0050] After mixing and stirring the urea-formaldehyde resin adhesive and disodium sebacic acid according to the ratio of 15:1 in mass ratio, a solid wood impregnation solution is obtained, wherein the solid content of the urea-formaldehyde resin adhesive is 22%;

[0051] (3) Solid wood dipped in glue

[0052] Add the solid wood impregnation solution into the impregnation treatment tank, then pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com