Textile printing and dyeing process

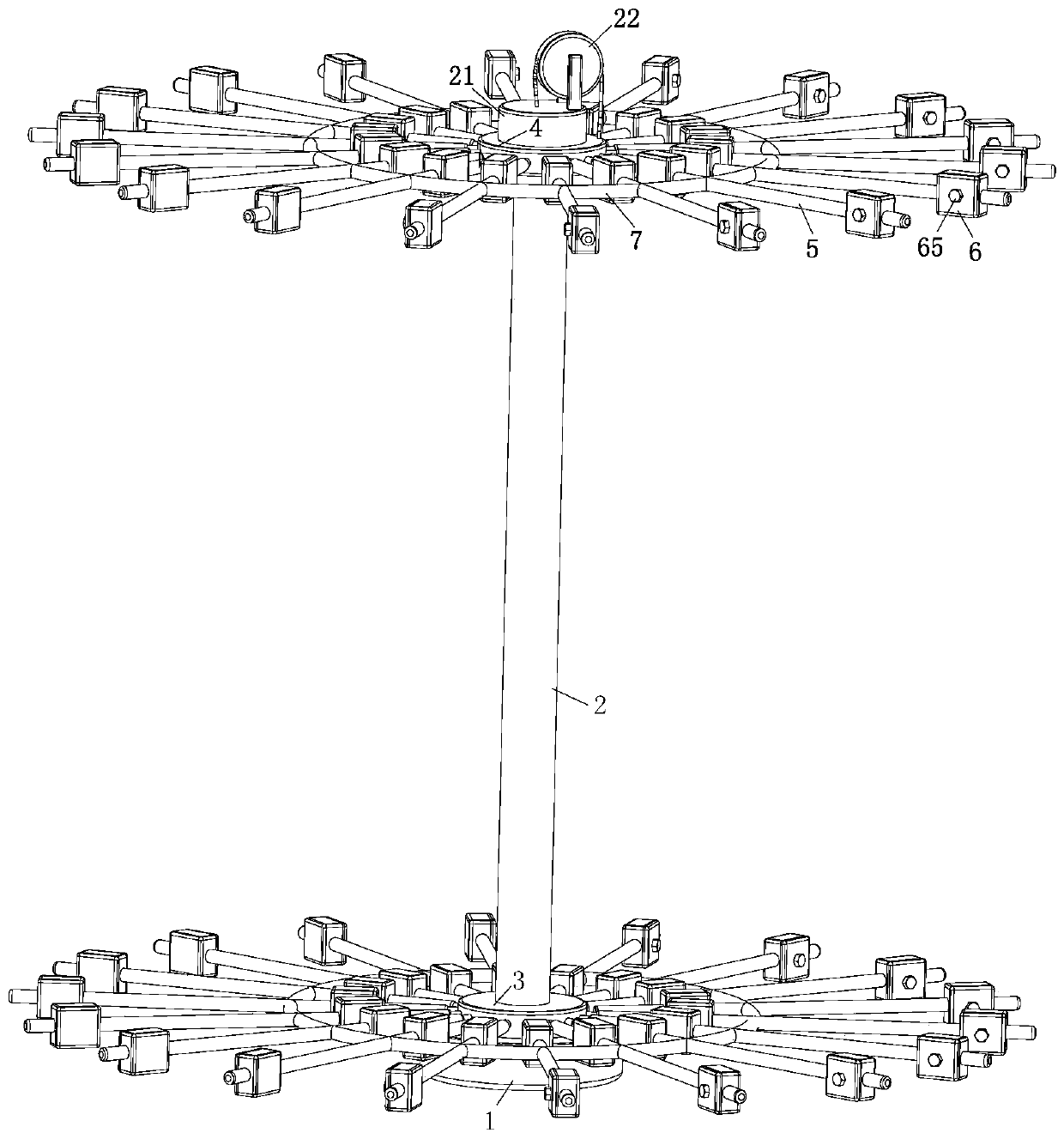

A technology of textile printing and dyeing, applied in the field of textile processing, which can solve the problems of inability to dry fabrics of different sizes and specifications, unfavorable fabric printing and dyeing, waste of electric energy, etc., to reduce shedding and damage, promote rapid shaking and air drying, Promote efficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

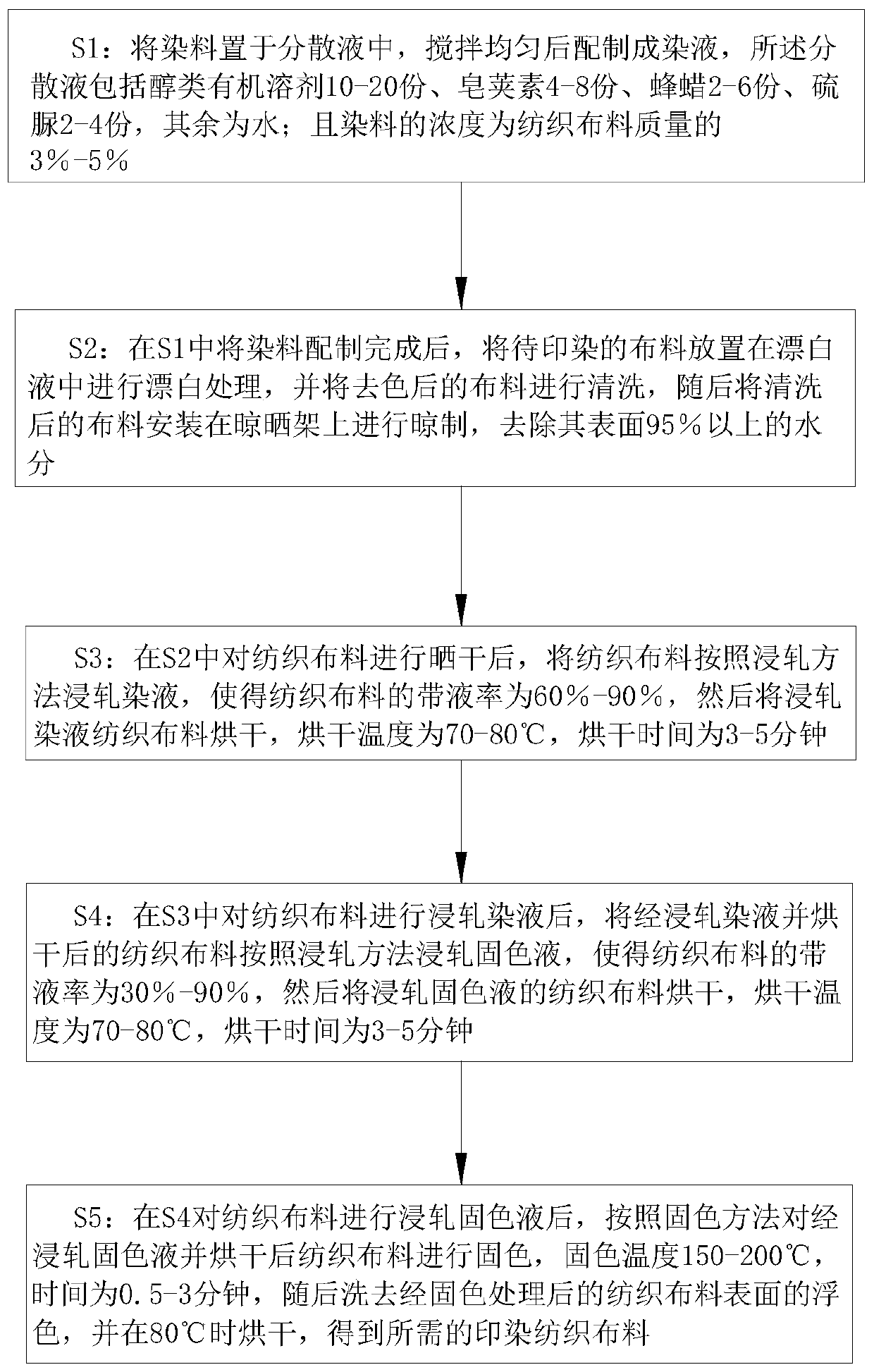

Method used

Image

Examples

Embodiment approach

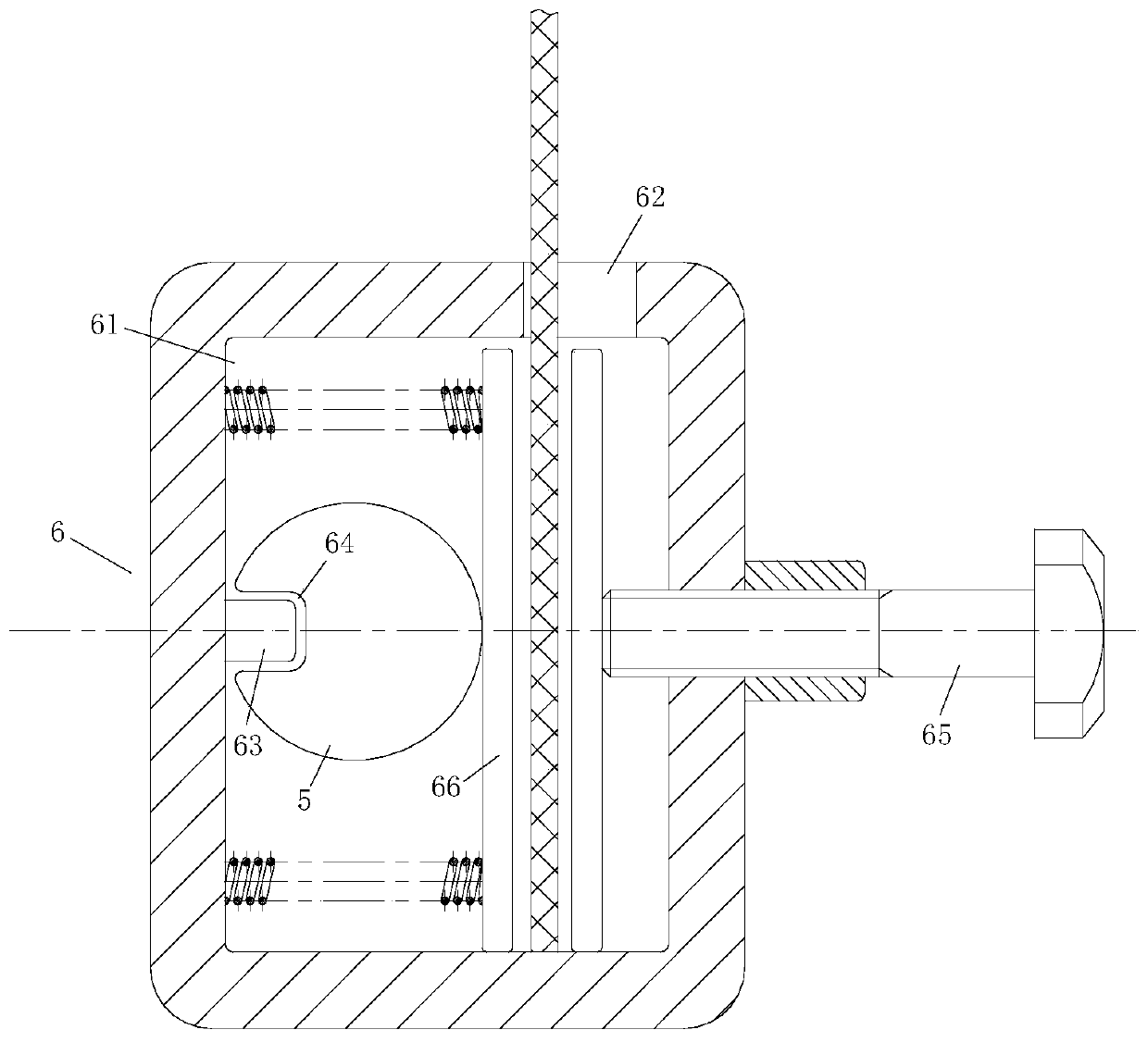

[0036] As an embodiment of the present invention, two fixing plates 66 are arranged inside the sliding chamber 61, and the middle part of the two fixing plates 66 is provided with a gap that enables the textile cloth to be inserted; When compacting and fixing, at this time, the end of the fastening bolt 65 is directly squeezed with the cloth on the side wall of the slide plate, which will easily cause damage and wrinkles at the press joint of the cloth, thereby affecting the appearance and use of the cloth; Between the two fixing plates 66, the active force of the fastening bolts 65 is fixed to the cloth located in front of the two plates through the two fixing plates 66, thereby effectively sharing the concentrated stress of the fastening bolts 65 on the cloth, thereby reducing the cloth in the Wrinkles and damage during the fixing process can effectively promote the smooth progress of the cloth printing and dyeing process.

[0037] As an embodiment of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com