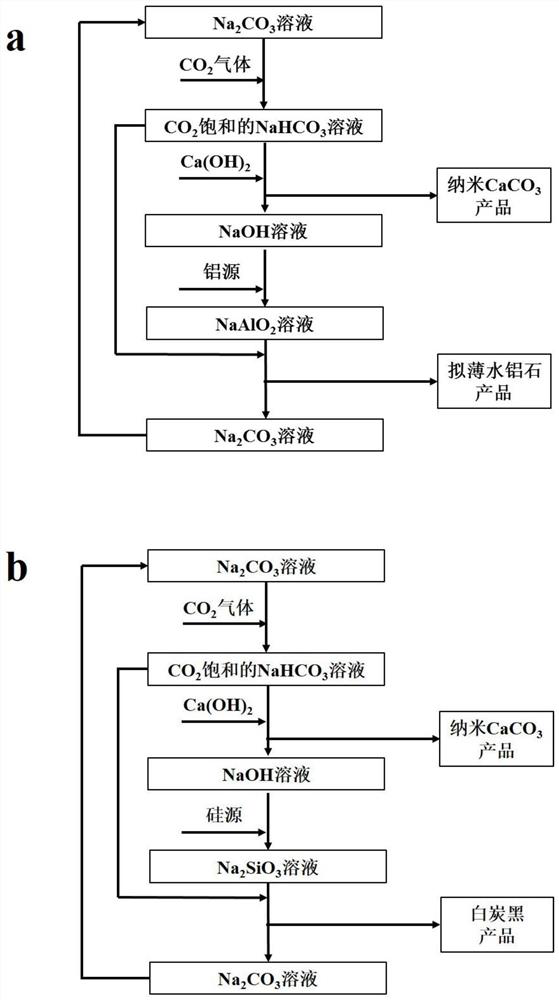

Combined preparation method of nano calcium carbonate and pseudo-boehmite or white carbon black

A technology of nano-calcium carbonate and pseudo-boehmite, which is applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problem of demanding gas influx and pH value control and affecting the nucleation of white carbon black and growth, reaction conditions are not easy to control, etc., to overcome the harsh reaction conditions, easy industrial production, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

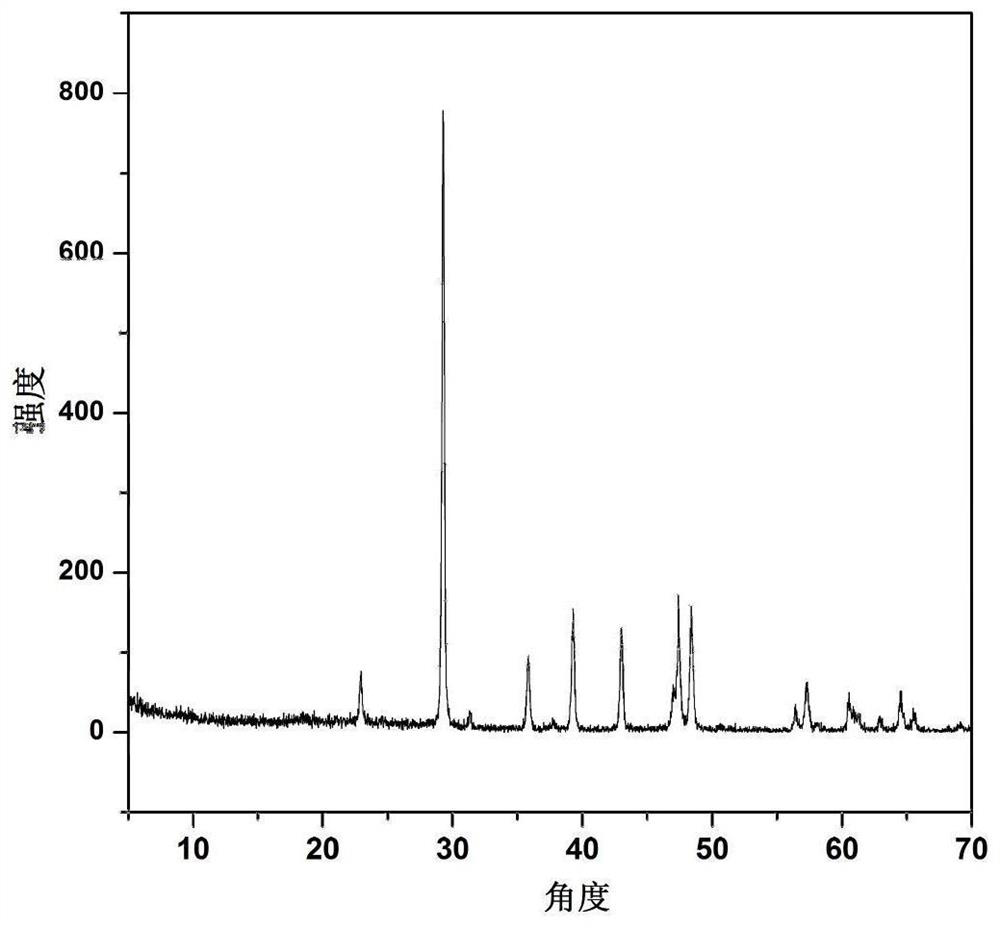

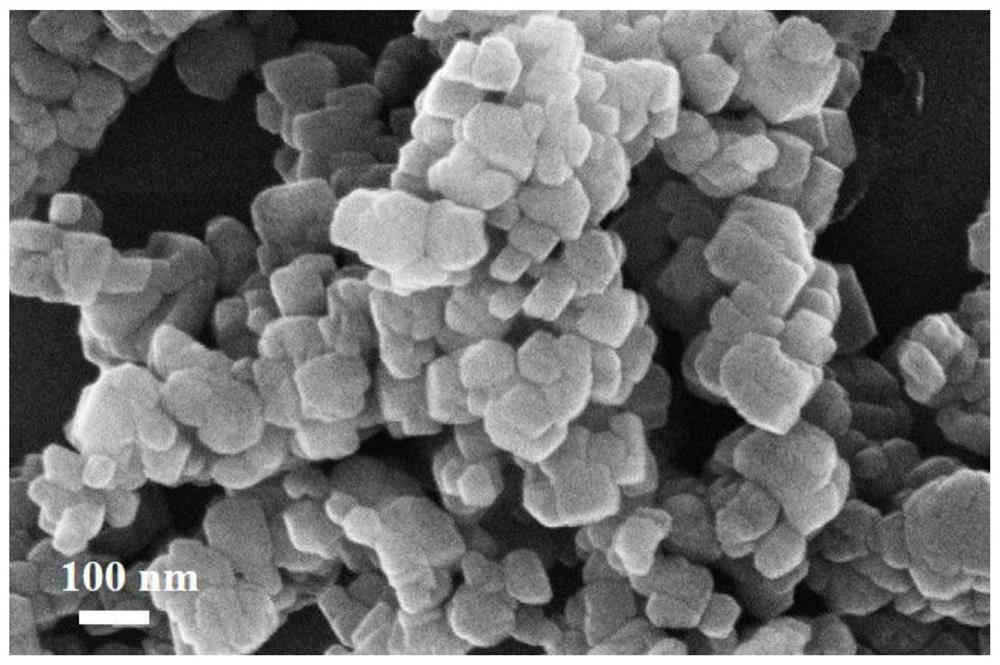

Examples

Embodiment 1

[0036] Step A: Weigh 106 grams of Na 2 CO 3 , added to deionized water to prepare Na with a concentration of 1mol / L 2 CO 3 solution, then to Na 2 CO 3 CO was introduced into the solution 2 gas to CO in solution 2 reaches saturation and obtains CO 2 saturated NaHCO 3 solution.

[0037] Step B: Take 0.5L of the NaHCO prepared in Step A 3 solution, weigh 5 g of sodium dodecyl sulfonate and add to NaHCO 3 solution and stir evenly; weigh 74 grams of Ca(OH) 2 Add to 600 grams of deionized water and grind for 5 minutes with a colloid mill to obtain Ca(OH) 2 slurry, NaHCO 3 Solution with Ca(OH) 2 The slurry was added to a colloid mill and ground for 6 minutes to obtain a nano-calcium carbonate slurry. The slurry was crystallized at 90°C for 1 hour, the precipitate was filtered, washed 6 times with deionized water, and then dried in an oven at 100°C for 3 hours, get nano CaCO 3 product. The NaOH mother liquor is reserved for future use, and the washing solution is store...

Embodiment 2

[0041] Step A: Take 0.5L of the Na obtained in Step 1 D 2 CO 3 mother liquor, into CO 2 gas to CO in solution 2 reaches saturation and obtains CO 2 saturated NaHCO 3 solution.

[0042] Step B: Take 0.25L of the NaHCO prepared in Step A 3 solution, weigh 5 g of sodium dodecylbenzenesulfonate and add to NaHCO 3 solution and stir evenly; weigh 37 grams of Ca(OH) 2 Add to 200 grams of deionized water and grind for 8 minutes with a colloid mill to obtain Ca(OH) 2 slurry, NaHCO 3 Solution with Ca(OH) 2 Add the slurry to the colloid mill at the same time and grind it for 10 minutes to obtain a nano-calcium carbonate slurry, and place it at 50°C for crystallization for 1 hour, filter the precipitate, wash it with the NaOH lotion in Example 1, and finally use deionized water Wash once, then dry in an oven at 95°C for 6 hours to obtain nano-CaCO 3 product. The NaOH mother liquor is reserved for future use, and the washing solution is stored in sequence according to the washi...

Embodiment 3

[0046] Step A: Weigh 159 grams of Na 2 CO 3 , added to deionized water to make Na with a concentration of 1.5mol / L 2 CO 3 solution, then to Na 2 CO 3 CO was introduced into the solution 2 gas to CO in solution 2 reaches saturation and obtains CO 2 saturated NaHCO 3 solution.

[0047] Step B: Take 0.5L of the NaHCO prepared in Step A 3 solution, weigh 10 g of polyacrylamide and add to NaHCO 3 solution and stir evenly; weigh 111 grams of Ca(OH) 2 Add to 1000 grams of deionized water and grind for 10 minutes with a colloid mill to obtain Ca(OH) 2 slurry, NaHCO 3 Solution with Ca(OH) 2 Add the slurry to a colloid mill at the same time and grind it for 10 minutes to obtain a nano-calcium carbonate slurry, and crystallize it at 50°C for 2 hours, filter the precipitate, wash it with deionized water 6 times, and then dry it in an oven at 120°C for 2 hours. get nano CaCO 3 product. The NaOH mother liquor is reserved for future use, and the washing solution can be reused...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com