Inspection device and ink-jet printing device therewith

An inspection device and image technology, used in textile material inspection, permanent visual display device, image analysis, etc., can solve problems such as low-quality printing and dyeing products, achieve high-precision detection, high-precision image defects, and suppress false detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

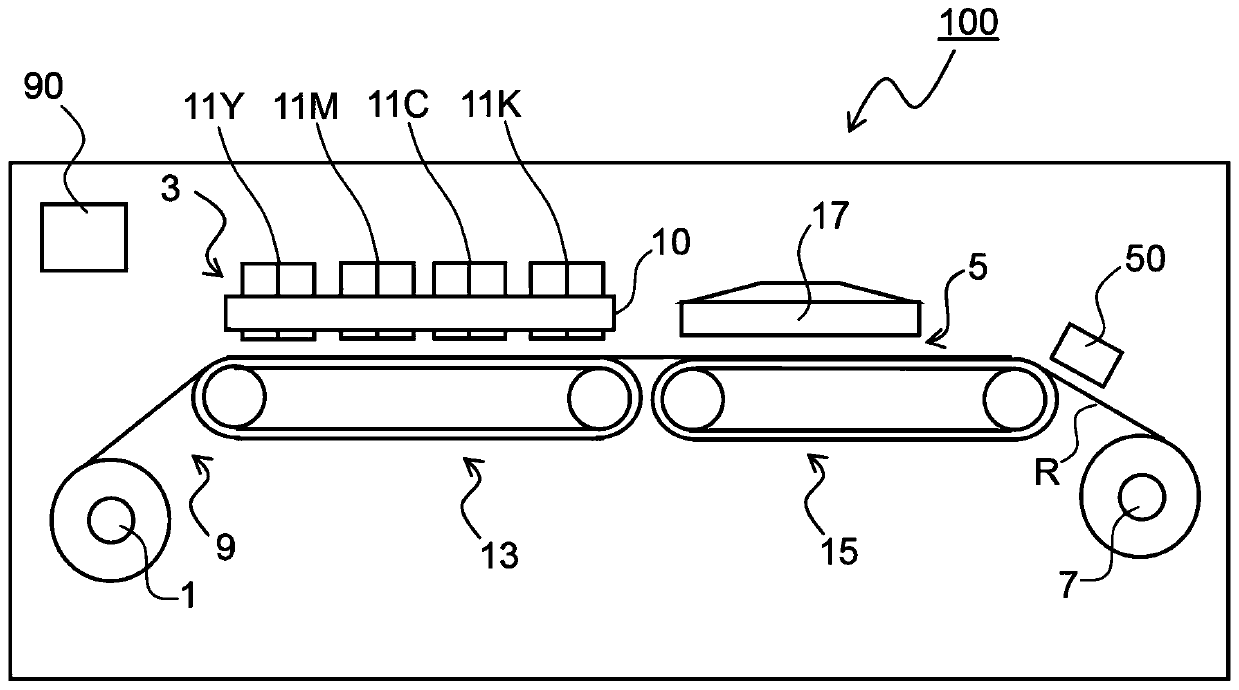

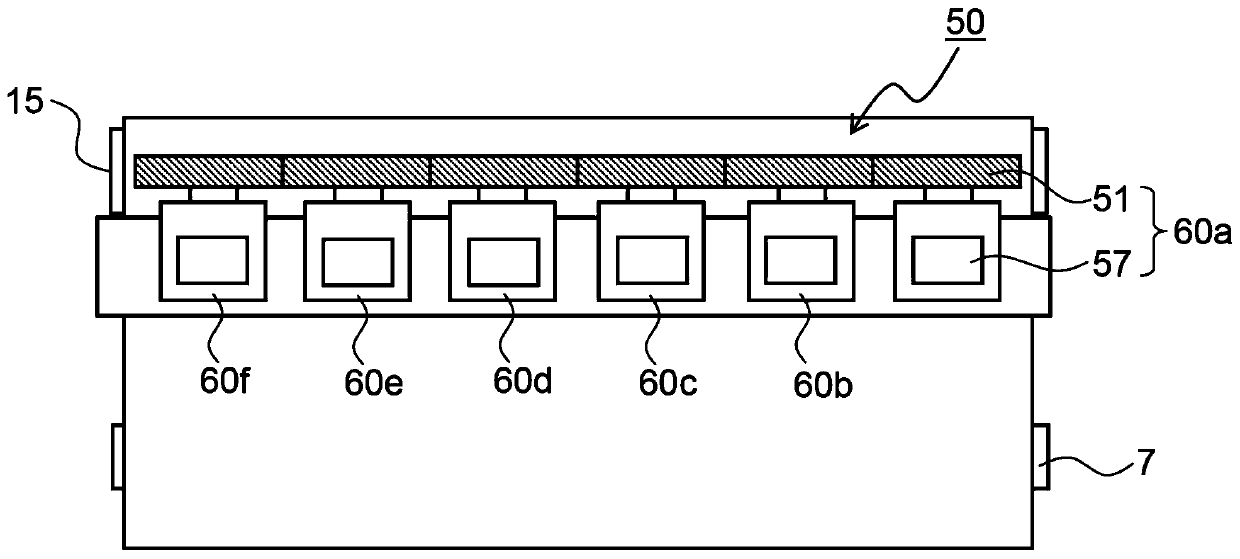

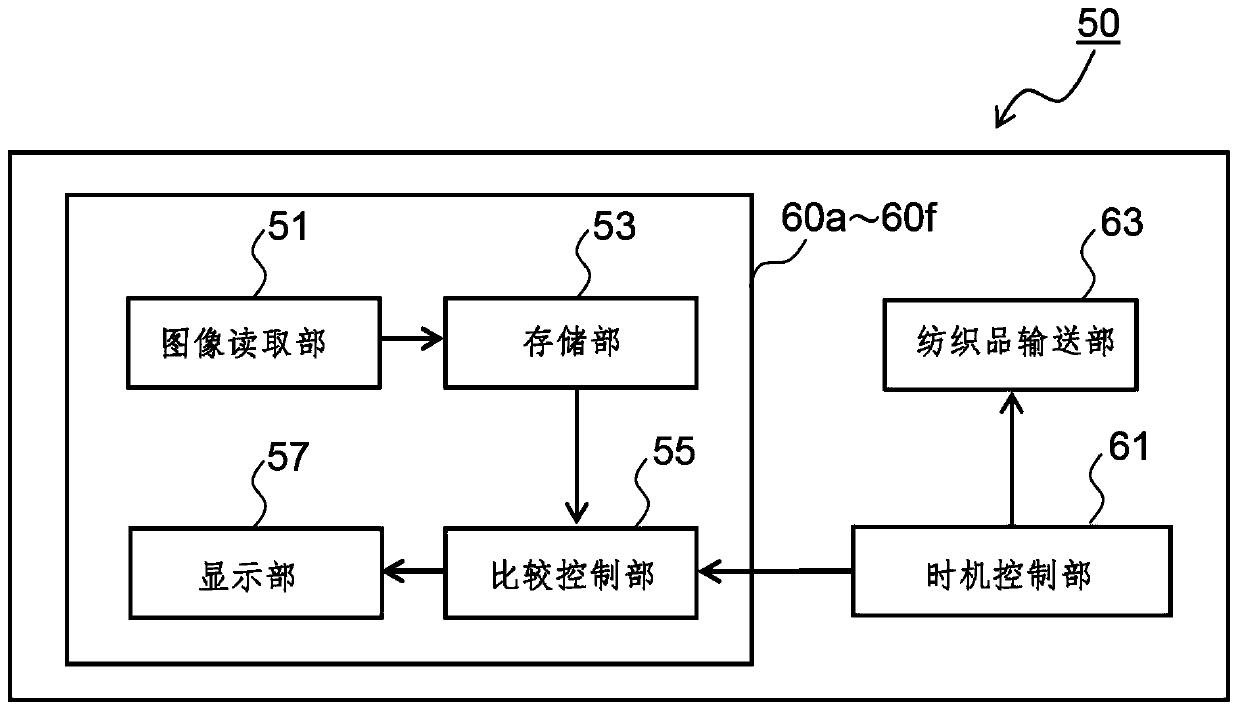

[0022] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a schematic diagram showing the overall structure of the inkjet printing and dyeing apparatus 100 provided with the inspection apparatus 50 of the present invention. The inkjet printing and dyeing device 100 prints and dyes the textile R by direct printing and dyeing, such as figure 1 As shown, it includes a textile extraction unit 1 , an inkjet recording unit 3 , a drying unit 5 , a textile recovery unit 7 , an inspection device 50 and a control unit 90 .

[0023] A long recording sheet, that is, a textile R is set on a textile delivery unit 1 provided on the upstream side of the inkjet recording unit 3 in the transport direction ( figure 1 to the left of the ). The woven fabric delivery unit 1 includes a rotating shaft on which a rolled woven fabric R is attached, and a motor (both not shown) that drives the rotating shaft to rotate in a predetermined rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com