Modular electric heating simulation heat source for ETG

An electric heating and modular technology, which is applied in ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of the absence of simulated heat sources, etc., and achieve the effects of reducing research costs, long life at high temperature, and speeding up research progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

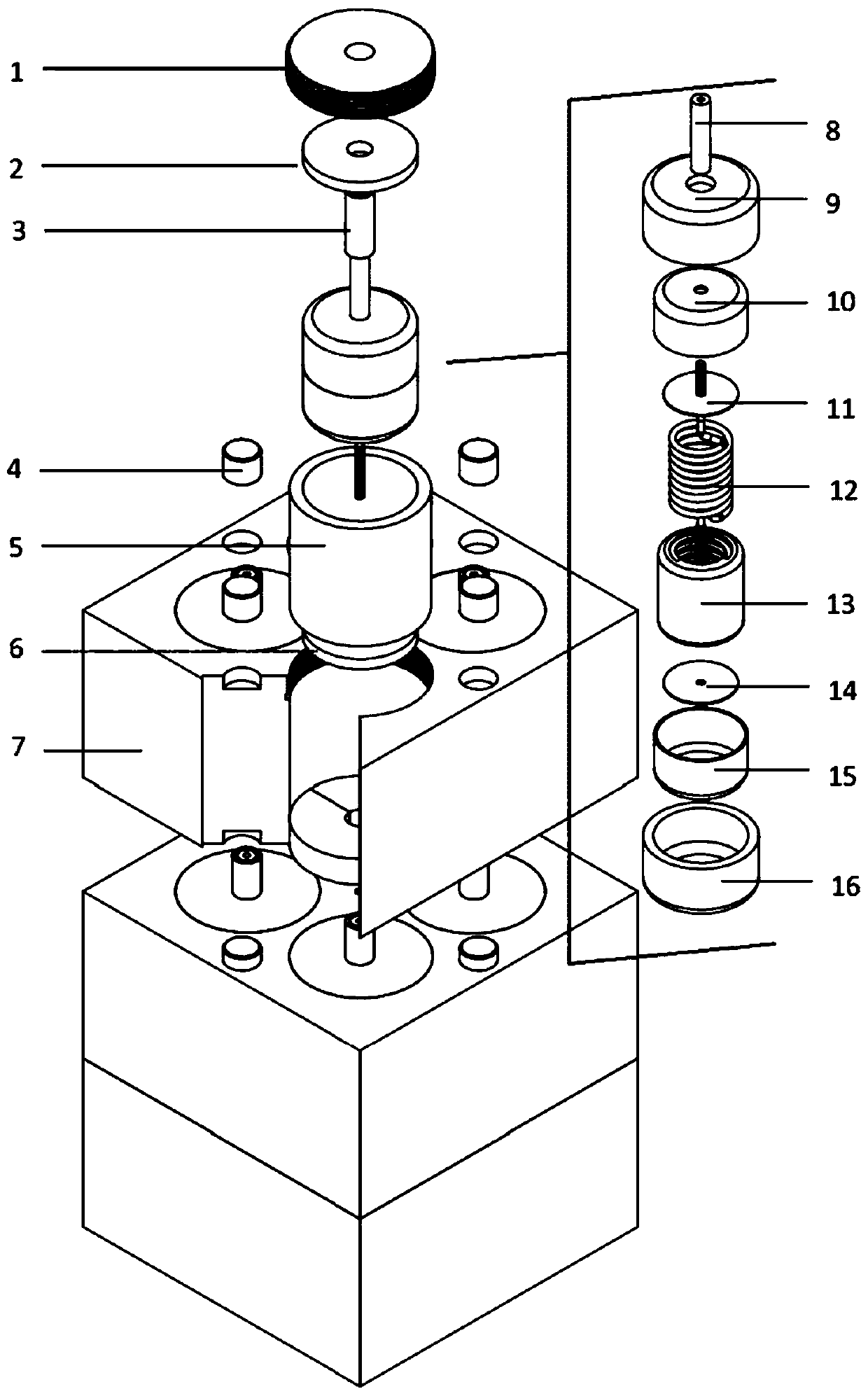

[0024] Such as figure 1 As shown, the present invention provides a modular electric heating simulation heat source for ETG, which includes at least two stacked modules; the modules include a module box and an electric heating unit arranged in the module box. The module box includes a module box main body 7 and a module box end cover 1, the number of end covers is consistent with the number of electric heating units; each module box is provided with at least two electric heating units, preferably four. The electric heating unit is wrapped with a heat insulation layer. The heat insulation layer includes a heat insulation layer cylinder body 5 , a heat insulation layer upper end cap 2 and a heat insulation layer lower end cap 6 .

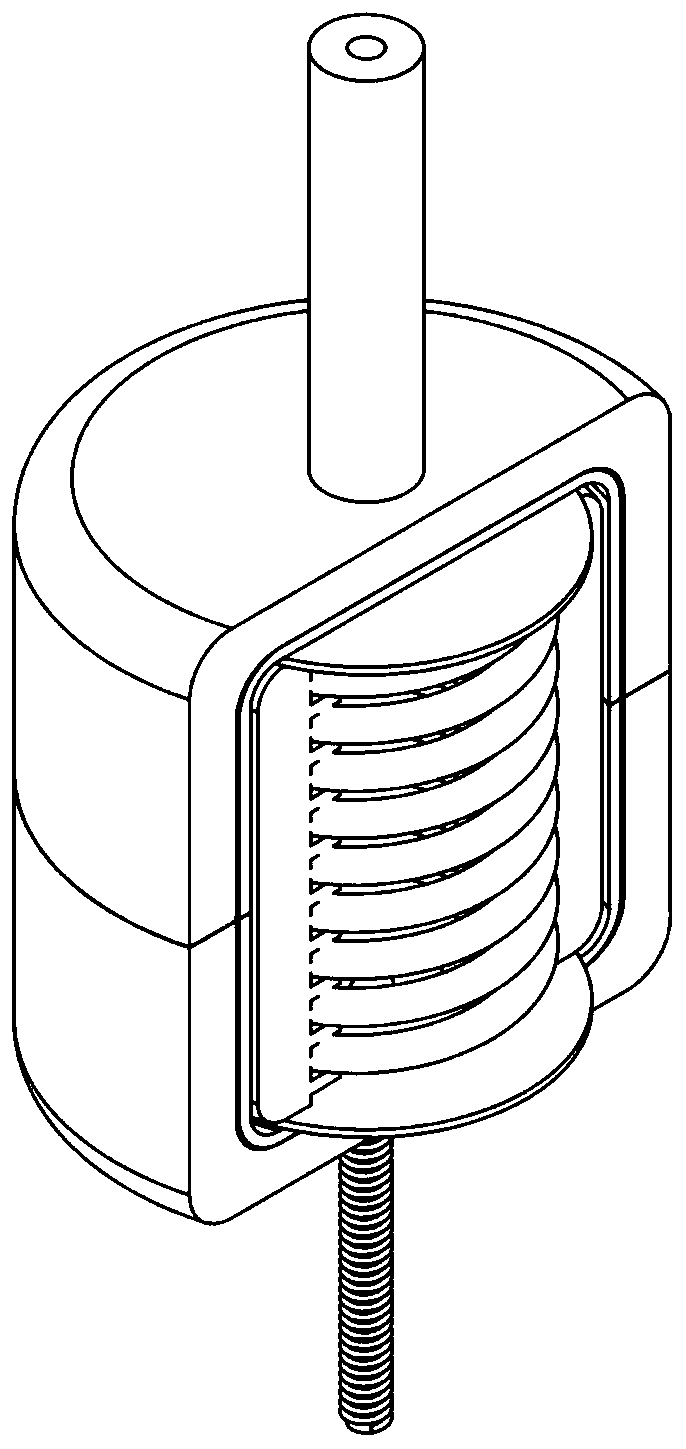

[0025] Such as figure 2 As shown, the electric heating unit includes a casing, a coil holding threaded pipe 13 and a res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com