Intermittent frying system and using method thereof

A fryer and oil tank technology, which is applied in separation methods, chemical instruments and methods, oil/fat baking, etc., can solve the problems of affecting the service life of processing equipment, slipping and falling of soot workers, and avoid overcooking and flavor reduction , Increase the speed of heat loss and quickly reduce the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

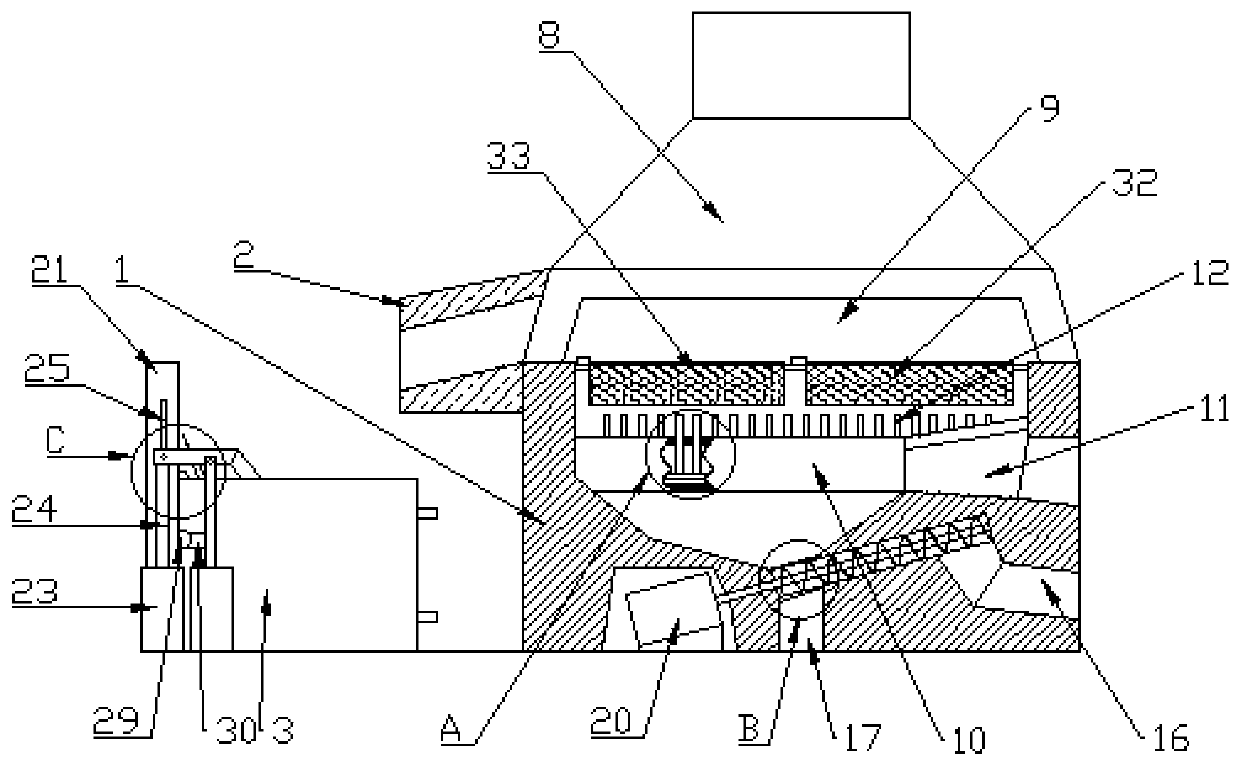

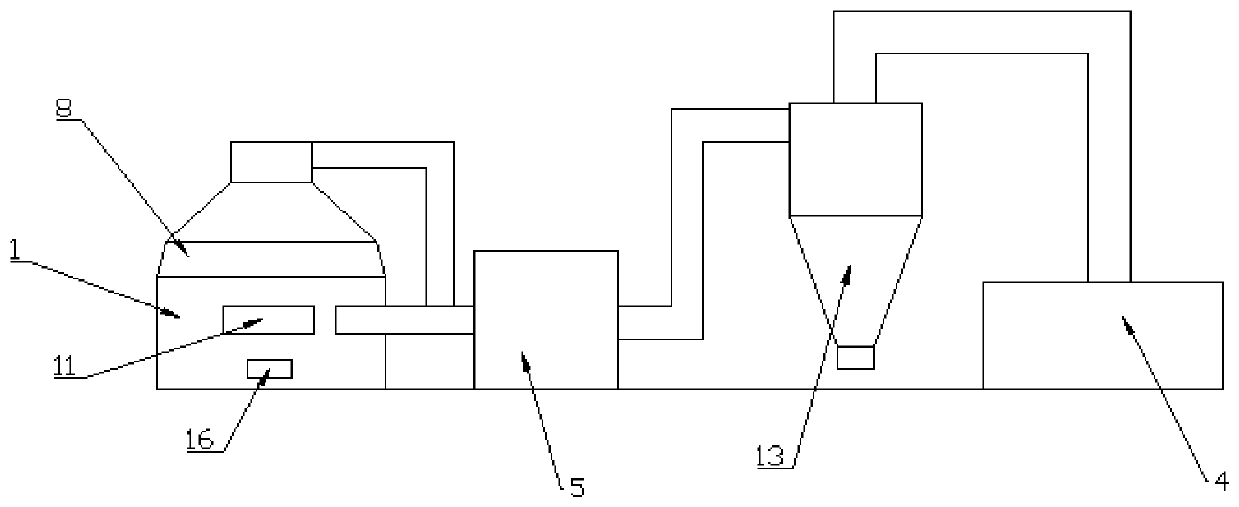

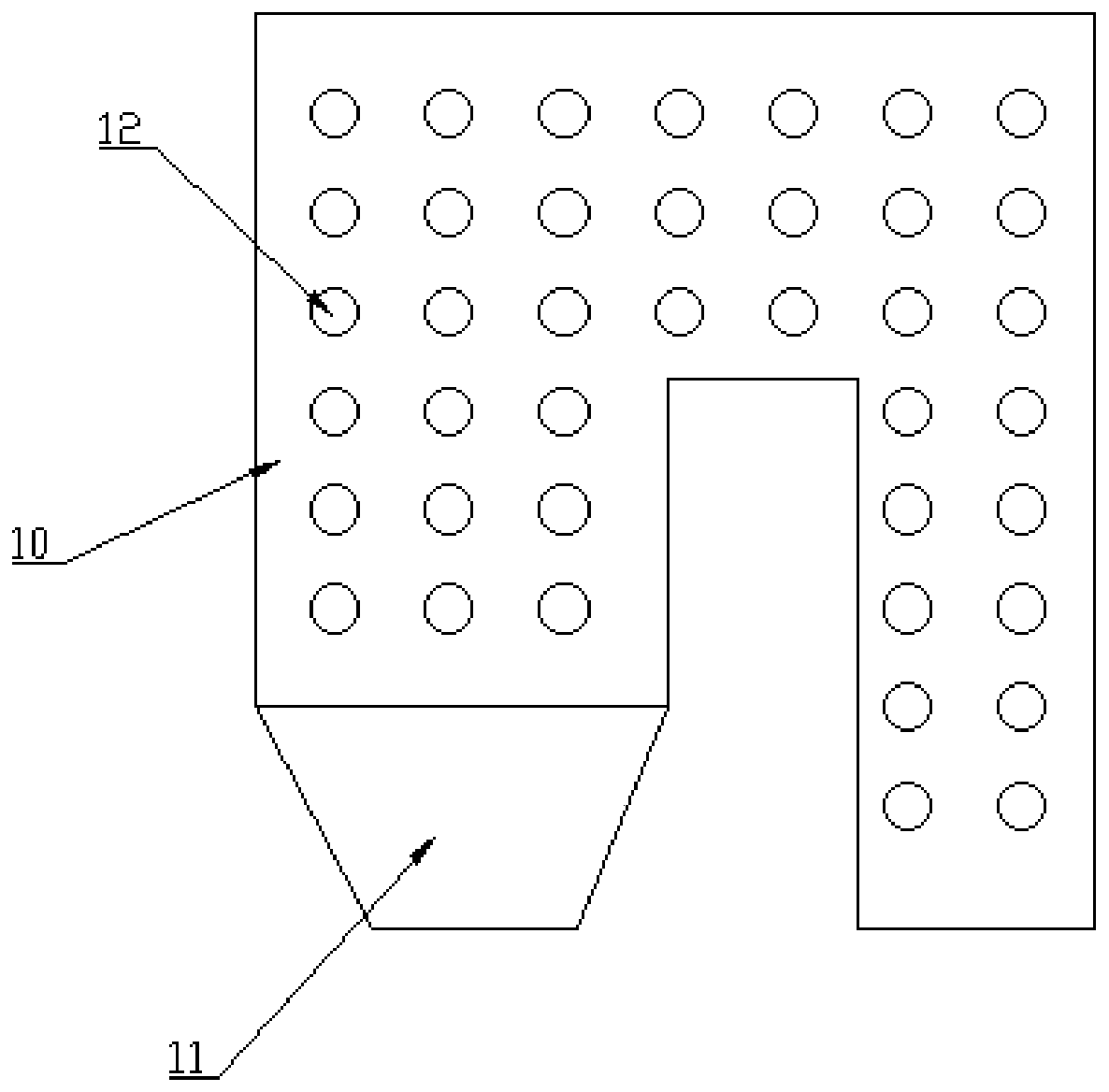

[0035] see Figure 1 to Figure 7 , a discontinuous frying system, comprising a fryer 1, a hopper 2 is arranged on the fryer 1, and a bubble barrel 3 arranged below the hopper 2, and the fryer 1 is connected with a sucker to generate The oil fume suction fan 4, and the electrostatic precipitator 5 communicating with each other is arranged between the suction fan 4 and the fryer 1; the foam material barrel 3 is provided with a foam material basket 6, and the foam material barrel 3 is provided with a foam supply basket 6. The lifting assembly that enters and exits the foam bucket 3, and the foam basket 6 is provided with a guide hopper 7 that facilitates the material to be exported when it is lifted to the highest point, wherein the fryer 1 is provided with a smoke collection cover 8, and the smoke The cover 8 is provided with an operation window 9 communicating with the fryer 1 and the outside world for feeding materials into the fryer 1 , and the electrostatic precipitator 5 co...

Embodiment 2

[0048] see Figure 1 to Figure 7 , a method for using an intermittent frying system, comprising the steps of:

[0049] Through the combustion chamber 11, a high-temperature zone 32 with a temperature of 180-260°C and a low-temperature zone 33 with a temperature of 120-180°C are formed in the fryer 1, and materials are put into the high-temperature zone 32 for high-temperature frying, and then transferred to a low-temperature zone. Zone 33 is for low-temperature frying, and then the material is introduced into the foaming material basket 6 through the discharge hopper 2 for foaming, and the second motor 28 is started at the same time to drive the pulsator 26 to rotate so that the temperature in the foaming material barrel 3 is maintained at 70-85 °C, after the foaming is completed, start the oil cylinder 23 to lift the foaming basket 6 away from the foaming barrel 3, and export the materials through the hopper 7.

[0050] In the above implementation, two frying temperature zon...

Embodiment 1 and 2

[0052] In above-mentioned embodiment 1 and 2:

[0053] The oil fume generated during frying will not spread into the workshop, and will be discharged outside the workshop after being treated by the electrostatic precipitator 5 and the cyclone separator 13, and the oil fume particles in it will not pollute the surrounding environment;

[0054] While dealing with soot, it can also deal with the soot generated by the combustion chamber 11, and the suction fan 4 can provide power for sucking the oil fume, and at the same time, it can also provide power for the combustion chamber 11 to generate heat and transmit it in the heat exchange channel 10;

[0055] The heat pipe 12 directly introduces the frying medium into the heat exchange channel 10 for heating, and transfers the heat to the fryer 1 through the frying medium. Since the heat exchange channel 10 is far away from the combustion chamber 11, the amount of heat and the transfer speed are uniform. Therefore, two frying temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com