Crushing device for treating impurities filtered out from sewage

A crushing equipment and filtration technology, which is applied in grain processing, chemical/physical processes, mixers with rotating stirring devices, etc., can solve the problems of difficulty in meeting crushing requirements, difficult fermentation of filtrate, long fermentation time, etc., to achieve Simple structure, good effect and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

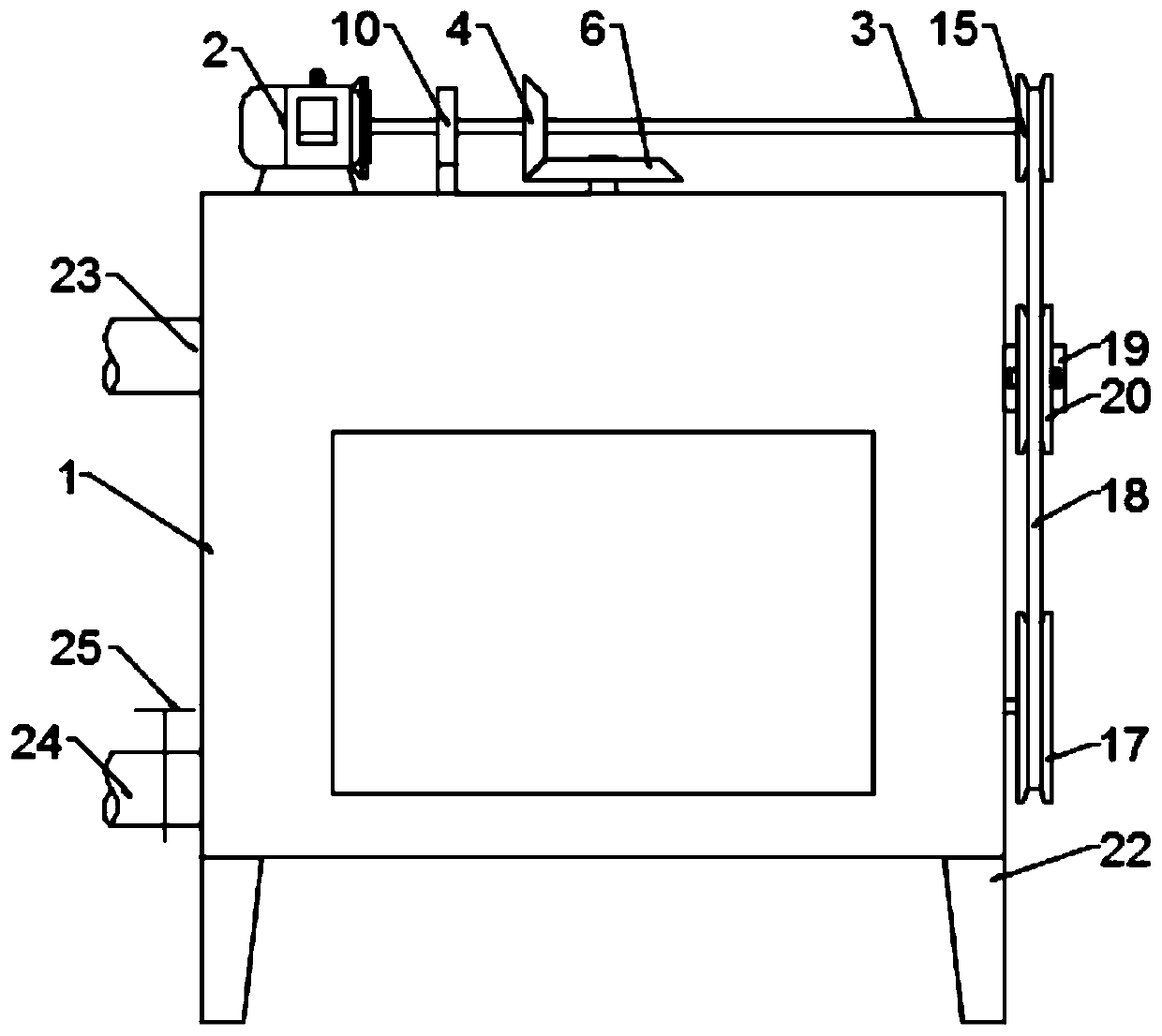

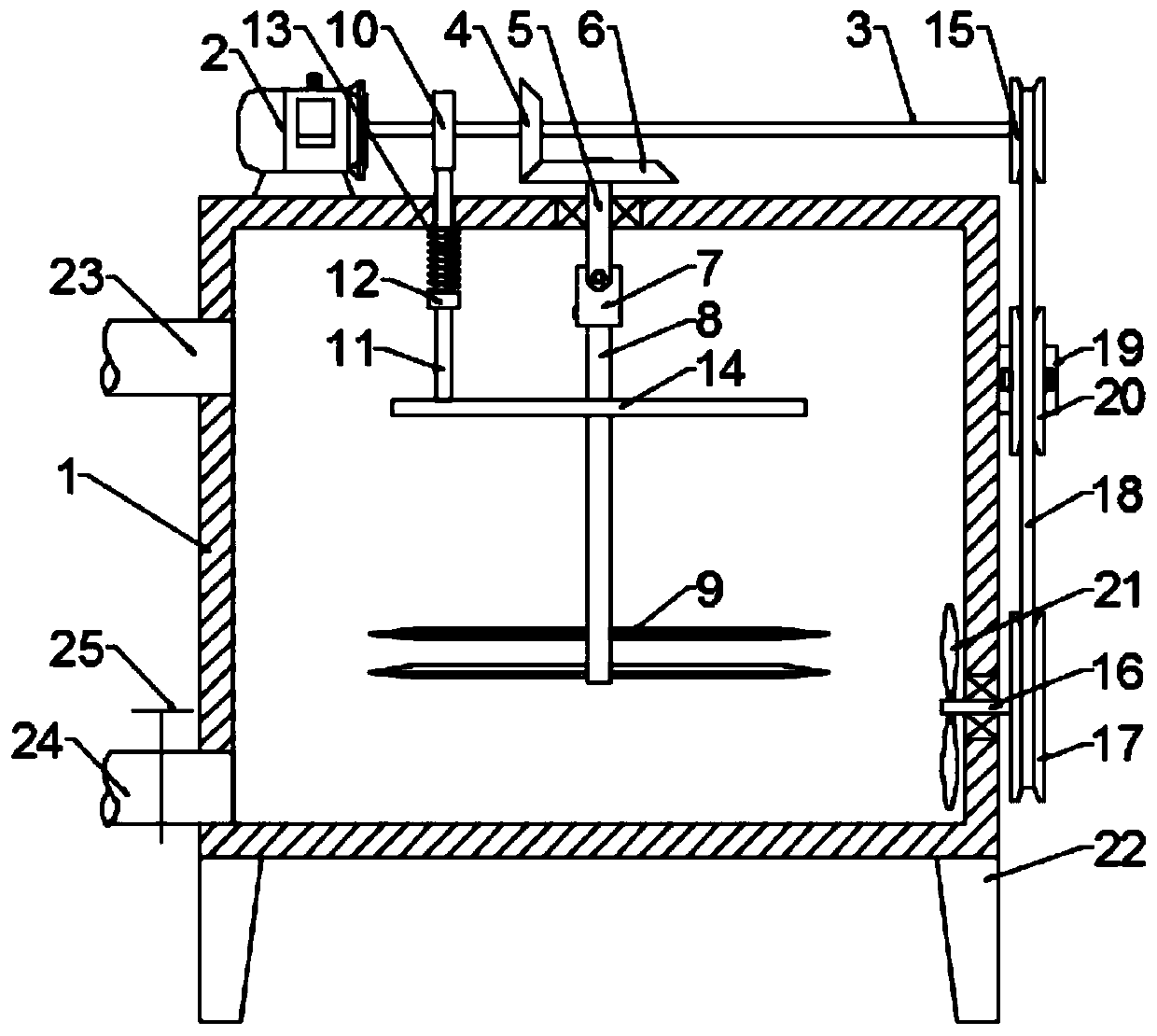

[0024] Example 1: Please refer to Figure 1-4 , a crushing device for treating impurities filtered out of sewage, comprising a crushing box 1, a motor 2 is fixedly connected to the top of the crushing box 1, a horizontal shaft 3 is fixedly connected to the output end of the motor 2, and a driving bevel gear is fixedly connected to the horizontal shaft 3 4. The top of the crushing box 1 is rotatably connected with a driven shaft 5, and the top of the driven shaft 5 is fixedly connected with a driven bevel gear 6, and the driven bevel gear 6 meshes with the driving bevel gear 4;

[0025] When in use, add the impurities filtered out of the sewage into the crushing box 1, turn on the motor 2, the rotation of the motor 2 drives the rotation of the horizontal shaft 3, the rotation of the horizontal shaft 3 drives the rotation of the active bevel gear 4, and then drives the driven shaft 5 through the driven bevel gear 6 turn;

[0026] The bottom of the driven shaft 5 is fixedly conn...

Embodiment 2

[0040] Embodiment 2: This embodiment is a further improvement of the previous embodiment: a ball is provided at the bottom of the longitudinal push rod 11, thereby avoiding damage to the rotating plate 14 caused by contact with the rotating plate 14 during the vertical movement of the vertical pushing rod 11. , A transparent observation window can be fixed on the crushing box 1, which is convenient for intuitive understanding of the crushing process.

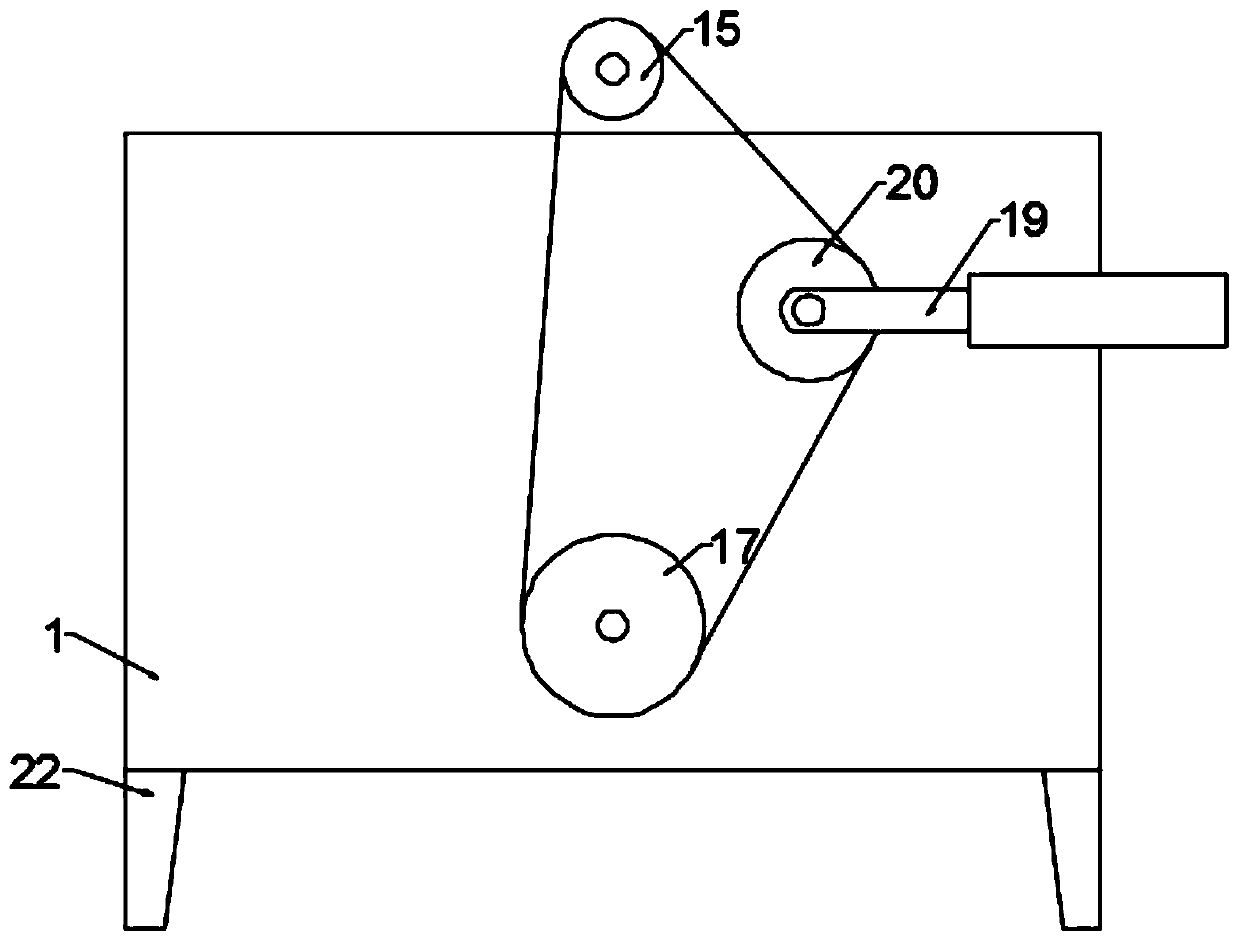

[0041]The working principle of the present invention is: when in use, add the impurities filtered out of the sewage into the crushing box 1, turn on the motor 2, the rotation of the motor 2 drives the horizontal shaft 3 to rotate, the rotation of the horizontal shaft 3 drives the rotation of the active bevel gear 4, and then passes through the driven cone The gear 6 drives the driven shaft 5 to rotate, and the rotation of the driven shaft 5 can drive the crushing shaft 8 to rotate through the universal coupling 7, and crush the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com