Bag electric dust remover for belt conveyor head and tail

A belt conveyor and dust collector technology, applied in electrostatic effect separation, chemical instruments and methods, dispersed particle filtration, etc., can solve problems affecting the safe, reliable and stable operation of dust removal devices, increasing operating costs, and occupying a large space. , to achieve the effect of significant energy saving, low operating cost and low operating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

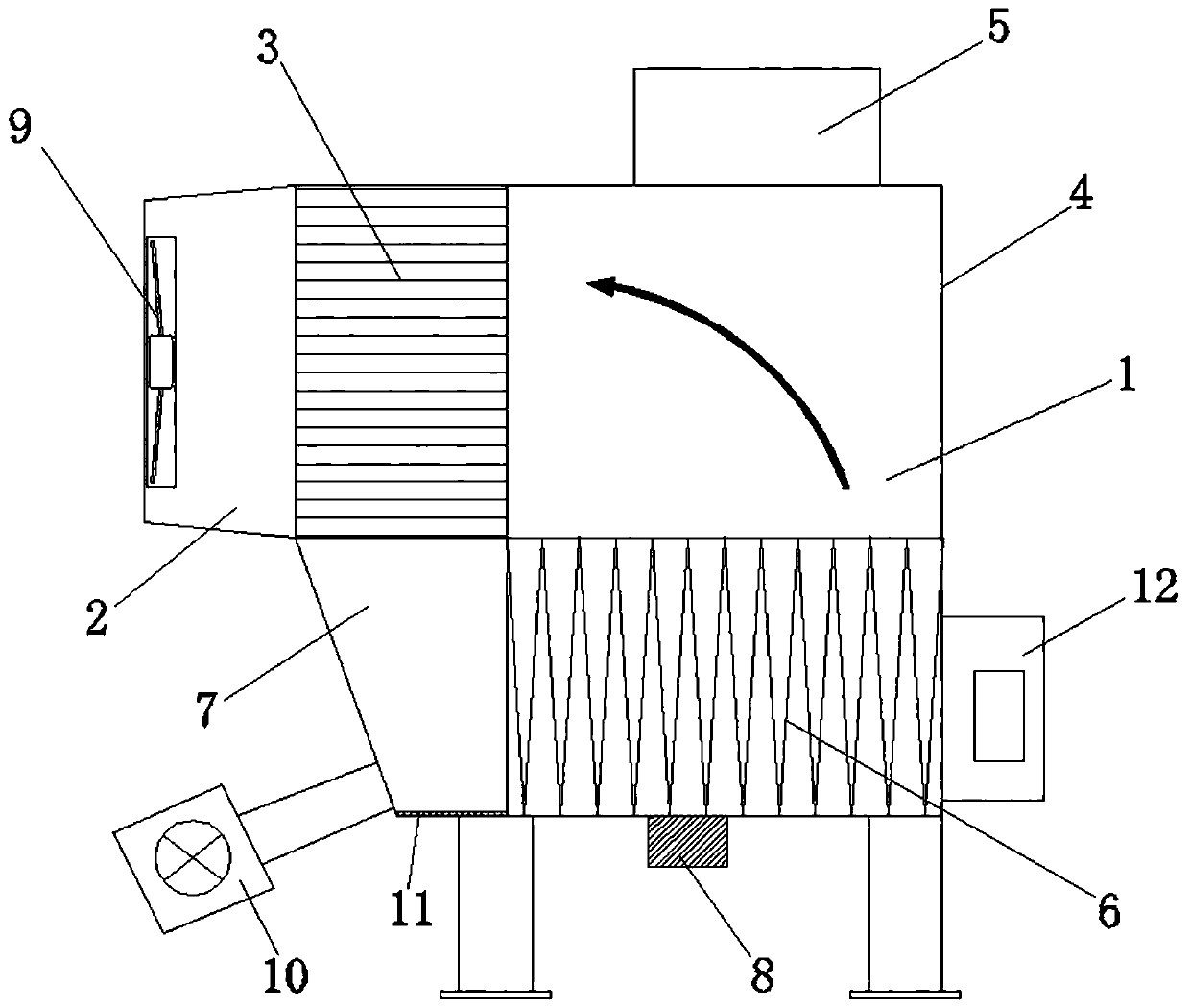

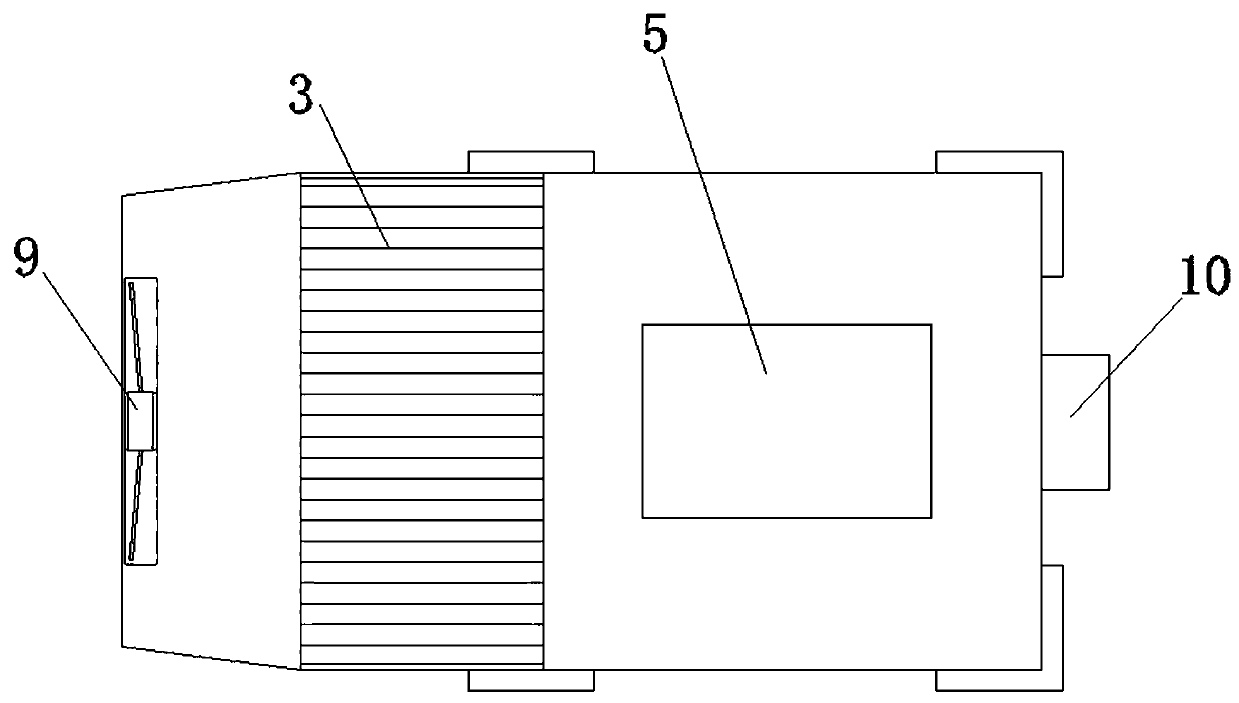

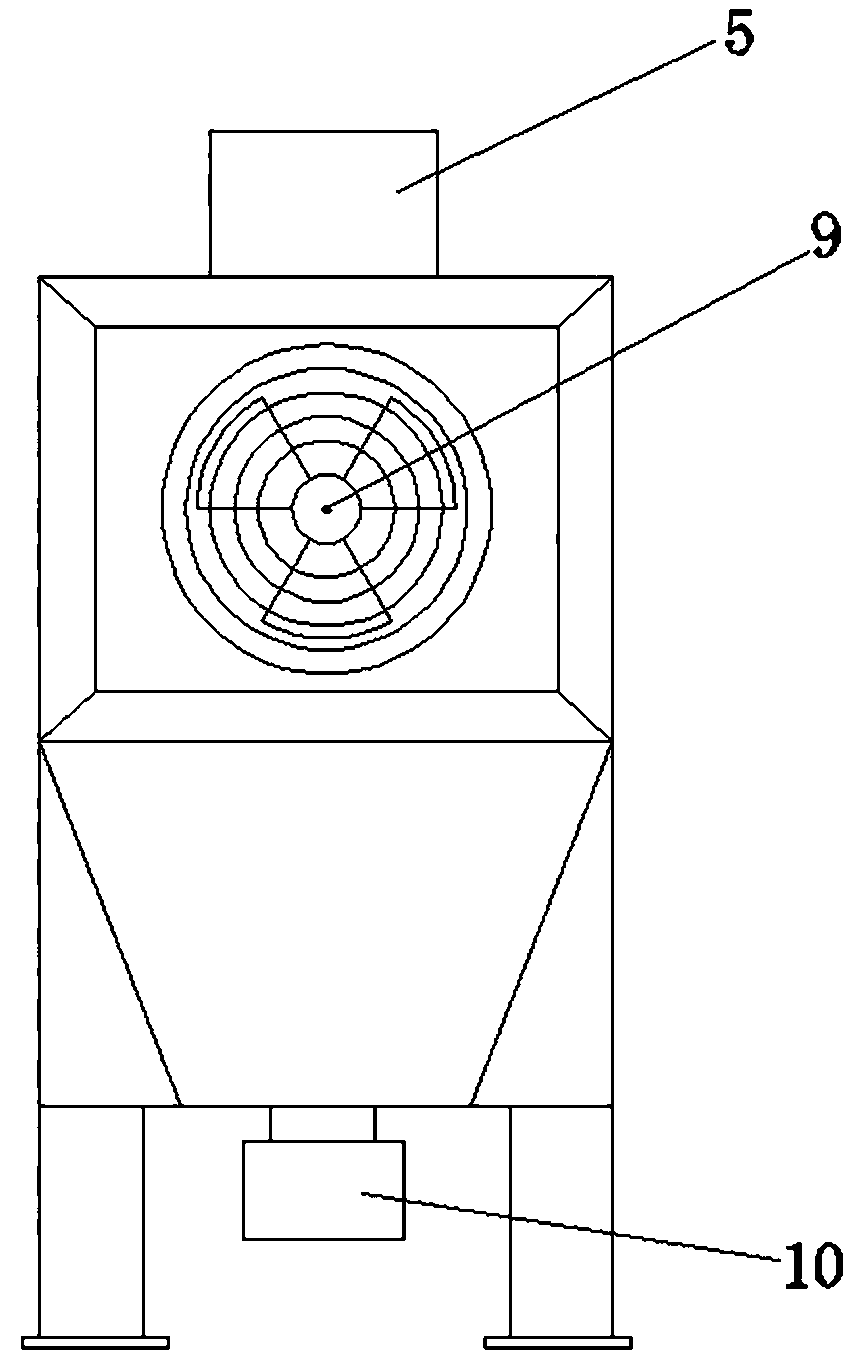

[0018] The present invention will be described below in conjunction with the accompanying drawings.

[0019] like Figure 1-3 As shown, the bag electrostatic precipitator used for the head and tail of the belt conveyor includes a dust collector housing 1, and the upper side of the dust collector housing 1 is sequentially provided with an air outlet channel 2, a plate-type high-voltage electrostatic field 3, and a mixed air Road 4; a high-voltage pulse generator 5 is provided above the mixing air duct 4, and a high-efficiency pre-filter bag 6 is provided below the mixing air duct 4; an air inlet channel 7 is provided on one side of the high-efficiency pre-filter bag 6, and the high-efficiency pre-filter bag The bottom of 6 is provided with automatic dust removal oscillator 8; the air outlet of air outlet channel 2 is provided with exhaust fan 9; An automatic ash unloading plate 11 is also provided at the bottom of the dust collector; a controller 12 is provided on the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com