Chromium polluted soil remediation material

A technology for chromium-contaminated soil and remediation materials, which is applied in the restoration of polluted soil and other directions, can solve problems such as intractability, and achieve the effects of convenient production, fast reaction rate, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] This specific embodiment adopts the following technical scheme: the chromium-contaminated soil remediation material is composed of the following parts by mass: CaSO 4 15%, CaS 4 21%, FeSO 4 21%, Ca(OH) 2 20%, AL(OH) 3 23%;

[0021] The preparation steps of the restoration material are as follows:

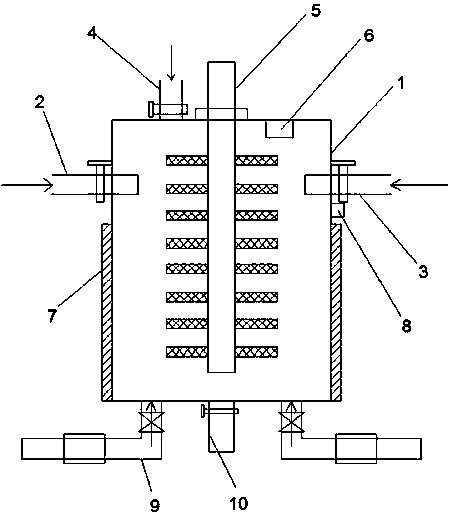

[0022] (1) Adjust the temperature of the reaction device to 110°C, and the CaSO 4 Added to the reaction device from the first feed port, CaSO 4 is 15%, then add AL(OH) to the reaction device from the second feed port 3 , Ca(OH) 2 , AL(OH) 3 23%, Ca(OH) 2 Mix and stir the three materials through the stirring shaft of the reaction device to fully react the three materials, keep the reaction temperature at 110°C, and the reaction time at 3H, CaSO 4 and AL(OH) 3 , Ca(OH) 2 The reaction produces layered double metal hydroxides;

[0023] (2) Add 21% CaS to the reaction device sequentially from the top feeding port 4 and 21% FeSO 4 , stir through the stirring shaft to...

specific Embodiment approach 2

[0026] This specific embodiment adopts the following technical scheme: the chromium-contaminated soil remediation material is composed of the following parts by mass: CaSO 4 17%, CaS 4 22%, FeSO 4 22%; Ca(OH) 2 21%, AL(OH) 3 24%;

[0027] The preparation steps of the restoration material are as follows:

[0028] (1) Adjust the temperature of the reaction device to 110°C, and the CaSO 4 Added to the reaction device from the first feed port, CaSO 4 17%, then add AL(OH) from the second feed port to the reaction device 3 , Ca(OH) 2 , AL(OH) 3 24%, Ca(OH) 2 The three materials are mixed and stirred through the stirring shaft of the reaction device to fully react the three materials, and the reaction temperature is kept at 110°C, and the reaction time is 3.5H. CaSO 4 and AL(OH) 3 , Ca(OH) 2 The reaction produces layered double metal hydroxides;

[0029] (2) Add 22% CaS to the reaction device sequentially from the top feeding port 4 and 22% FeSO 4 , stir through the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com