Multilayer door plate hot-pressing gluing device capable of continuously operating

A technology of gluing machine and door panel, applied in the field of gluing machine, can solve the problems of difficult door panel production, large space occupation, long length of the whole equipment, etc., to achieve the effect of not easily adhering to any substance, reducing the overall height and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

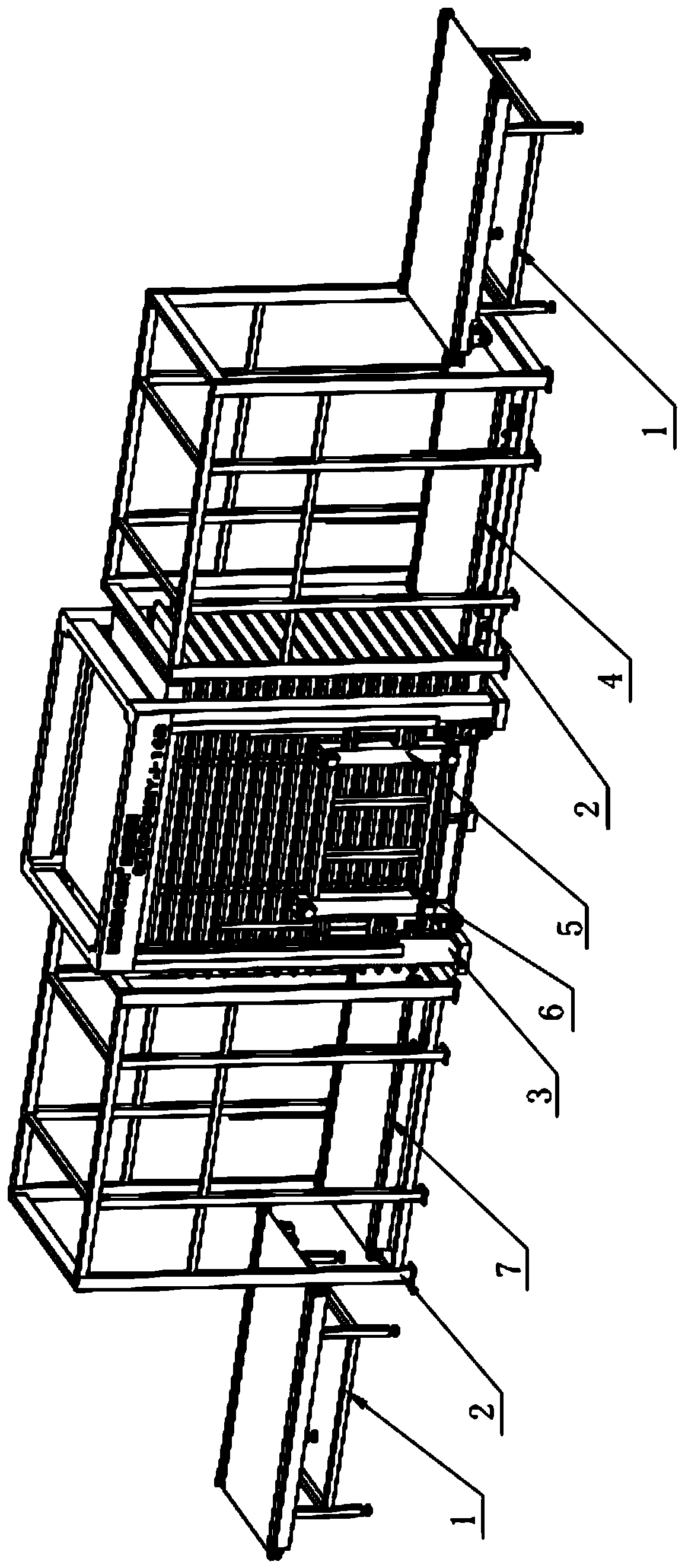

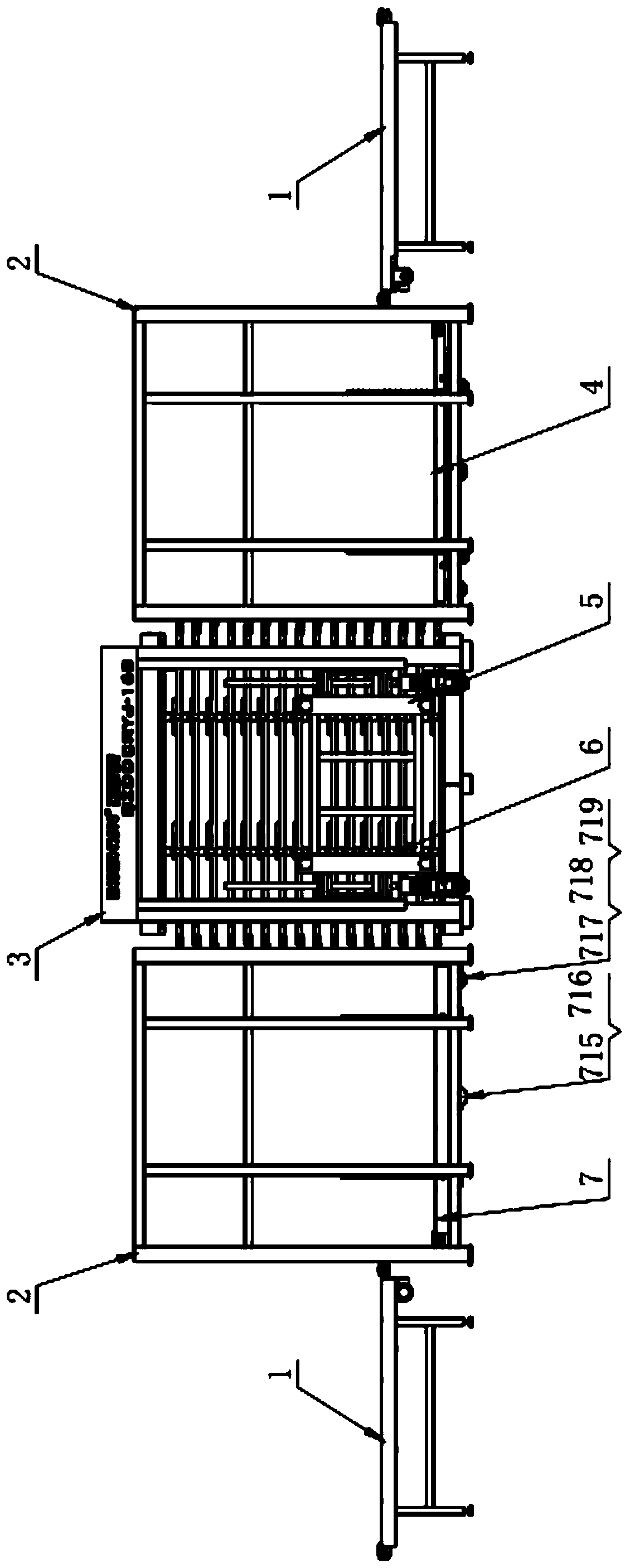

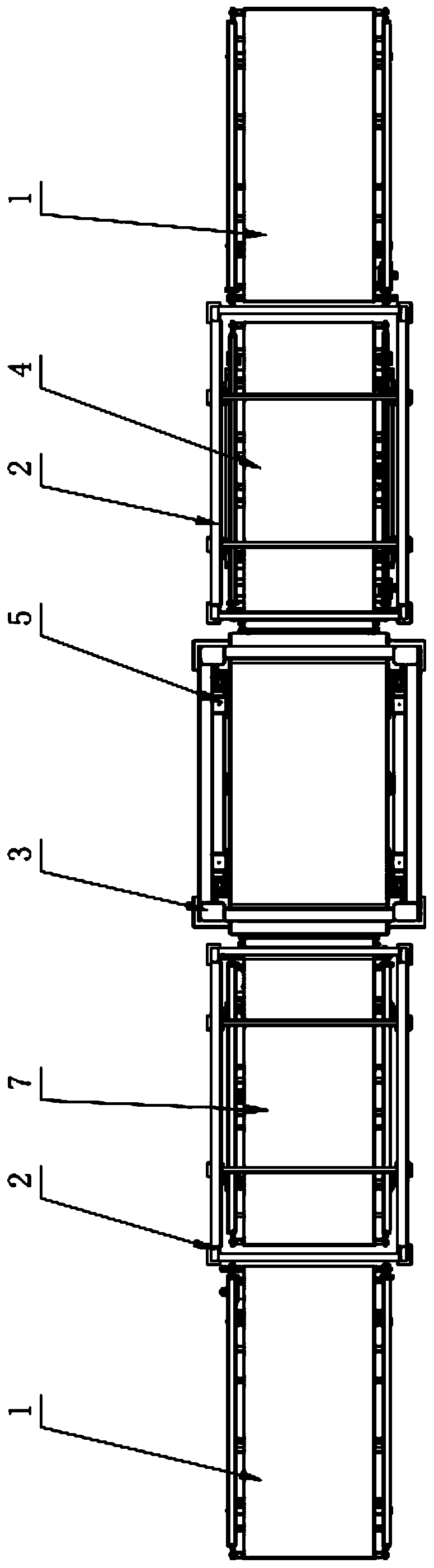

[0029] Figure 1 to Figure 11As shown, it is a specific embodiment created by the present invention, which includes correspondingly installed in and out conveying wire racks 2, feeding conveying lines 4, discharging conveying lines 7, feeding and discharging auxiliary lines 1 and fixedly installed on the main machine 3 inlet and outlet. The insertion and lifting mechanism 5 on the main frame 3, the fast-fitting height-setting mechanism 6, the insertion and lifting mechanism 5 includes a reducer mounting seat 503 fixed on the main frame 3, a servo motor 501 installed on the reducer mounting seat 503, Speed reducer 502, the shaft coupling 504 that connects speed reducer 502 output shaft and screw pair 505, is equipped with balance frame 506 on the nut of screw screw pair 505, is installed on the balance frame 506 limited support wheel 507, inserts and lifts cylinder 508, The latch 509, the latch 509 on the inserting and lifting mechanism 5, under the action of the inserting an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com