Single-cylinder glue injection mechanism of injection molding machine

An injection molding machine and injection technology, applied in the field of single-cylinder injection mechanism of injection molding machine, can solve the problems of difficult assembly, complex structure, low injection pressure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

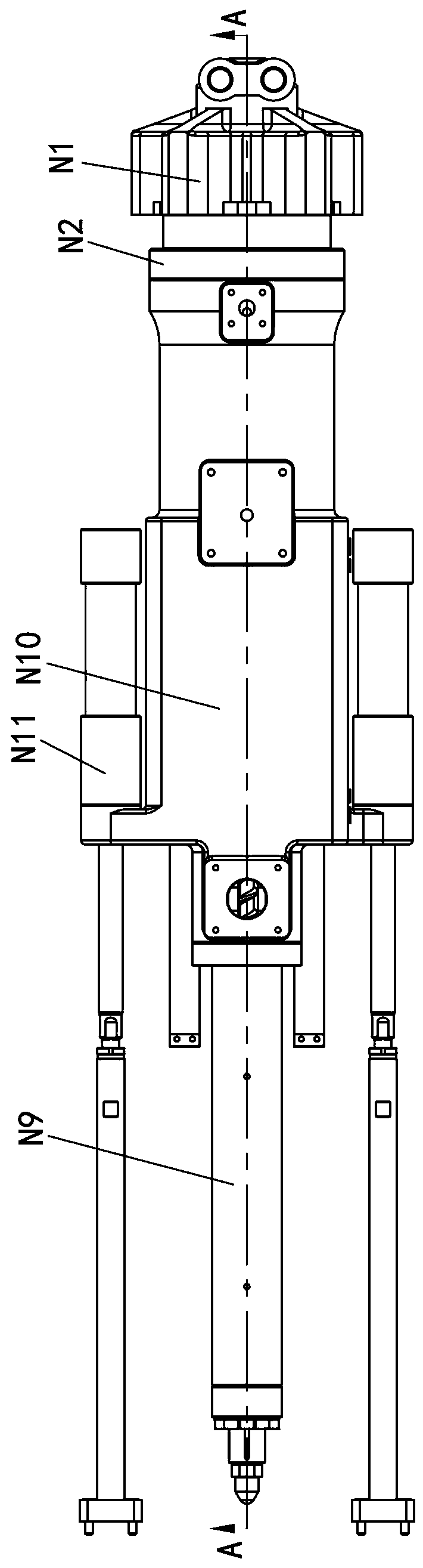

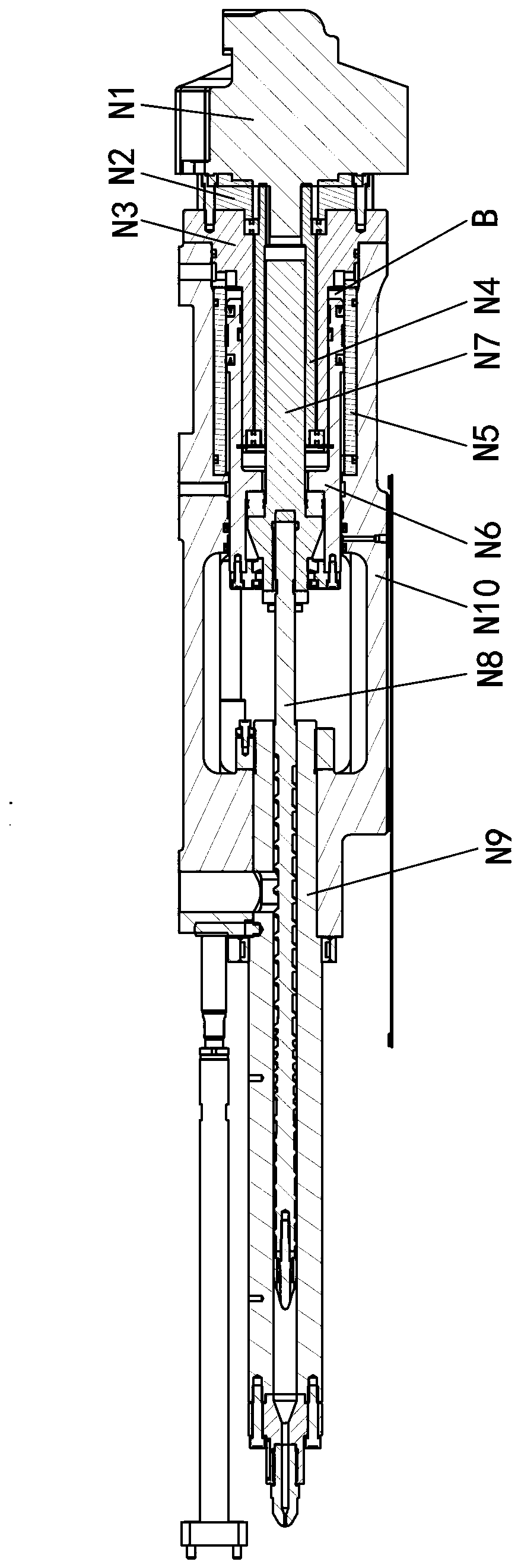

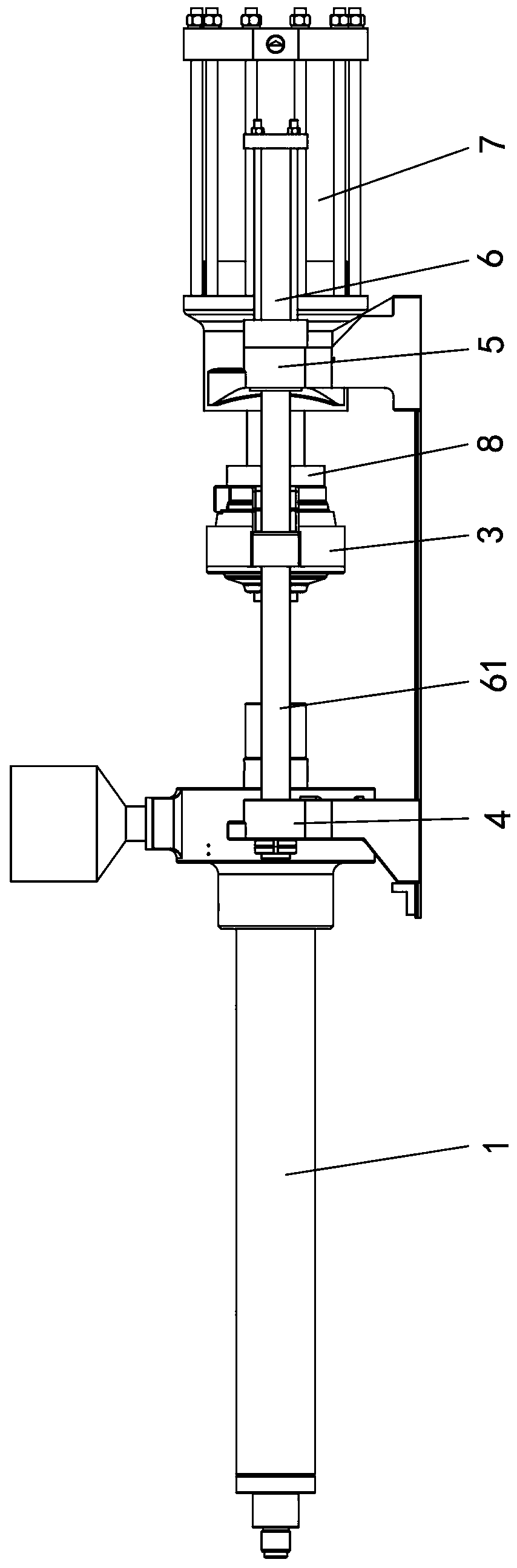

[0025] Embodiment one, see Figure 3-4 As shown, a single-cylinder injection mechanism of an injection molding machine includes a barrel 1, an injection screw 2, a melt motor 3, an injection head plate 4, an injection tail plate 5, a guide post 61, an injection cylinder 6 and an injection cylinder. Glue cylinder 7.

[0026] In this embodiment, there are two shooting cylinders 6 , and the telescoping ends of the shooting cylinders 6 constitute the guide post 61 .

[0027] Wherein, the telescopic end of the injection cylinder 6 passes through the injection tail plate 5 and the injection head plate 4 and is locked and fixed by a limit pin and a nut, and the injection tail plate 5 is slidably connected with the telescopic end of the injection cylinder 6,

[0028] The tail of the gun barrel 1 is fixed on the glue injection head plate 4, the melt glue motor 3 is arranged between the glue injection head plate 4 and the glue injection tail plate 5, and between the telescopic ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com