Method for resource utilization of waste incineration slag

A waste incineration slag recycling technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as methods and equipment for resource utilization of waste incineration slag that have not yet been seen, and achieve high utilization Value, good application prospects, and the effect of breaking the singleness and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

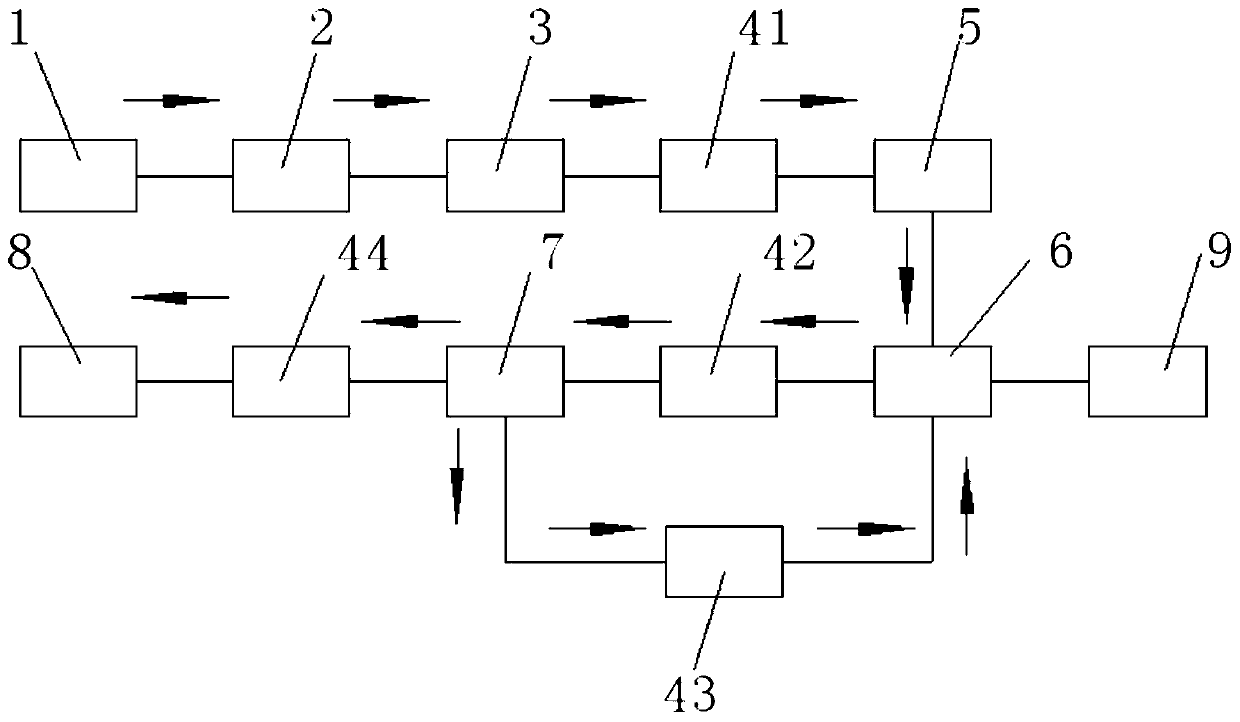

Image

Examples

Embodiment 1

[0039] A method for resource utilization of waste incineration slag, comprising the following steps:

[0040] (1) Preparation of waste incineration slag into slag sand products, specifically:

[0041] (1.1) The garbage incineration slag is transported by a special transport vehicle to the designated storage room, from the storage room through the loader to the vibrating feeder (preferred vibrating feeder screen size 1500*4000, motor power 2*2.2 KW, processing capacity 10-40t / h), the vibrating feeder is mainly to remove the lumps with too large particle size.

[0042] (1.2) Drop the remaining slag from the lumps removed in step (1.1) directly into the crusher (preferably jaw crusher model: PE250*400), and crush the slag to 40-100mm.

[0043] (1.3) The slag in step (1.1) is transported to the iron remover (preferred model: RCYD(C)-6.5) through the first conveying belt, and the iron materials are separated, and the iron materials are collected by the collector.

[0044] (1.4) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com