High-solid-content polyurethane emulsion and preparation method thereof

A polyurethane emulsion, high solid content technology, applied in the field of water-based polyurethane, can solve the problem of low solid content of polyurethane emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

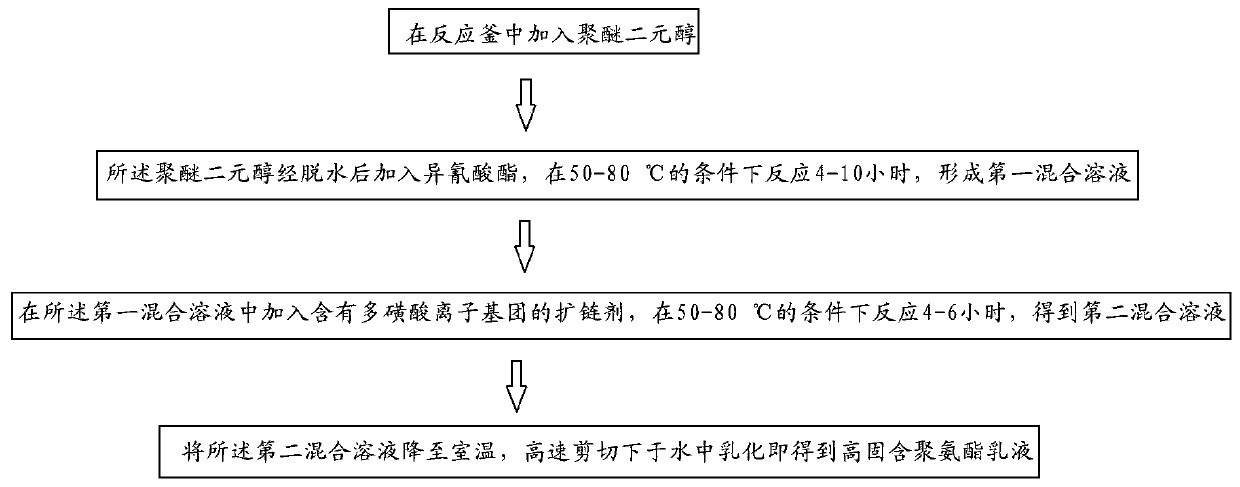

[0039] see figure 1 , based on the same inventive concept, the application also provides a method for preparing a high-solid polyurethane emulsion, comprising the following steps:

[0040] Step 1, add polyether diol in the reactor.

[0041] Step 2: add isocyanate to polyether diol after dehydration, and react at 50-80° C. for 4-10 hours to form a first mixed solution.

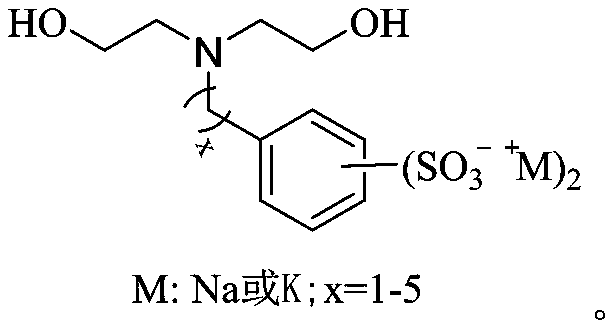

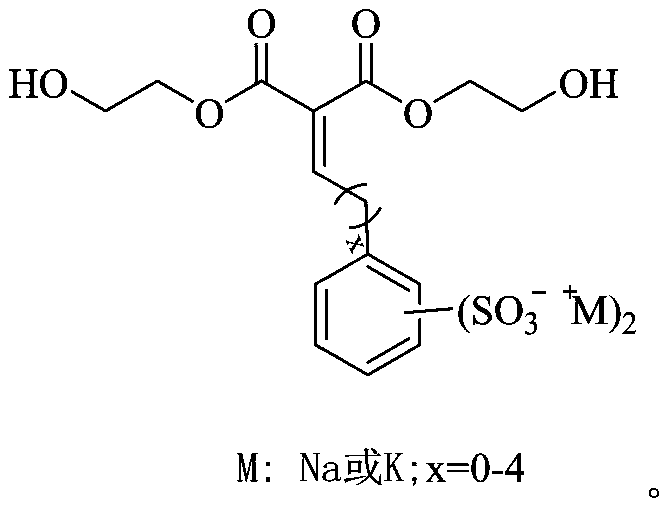

[0042] Step 3, adding a chain extender containing polysulfonic acid ion groups to the first mixed solution, and reacting at 50-80° C. for 4-6 hours to obtain a second mixed solution.

[0043] In step 4, the second mixed solution is lowered to room temperature, and emulsified in water under high-speed shear to obtain a high-solid polyurethane emulsion.

[0044] The preparation method of the present application is simple, easy to enlarge the operation process and realize industrial production. Since the chain extender of the polysulfonic acid ionic group used contains multiple ionic groups, the long-term stabi...

Embodiment 1

[0047] Add 10g of polyethylene glycol (molecular weight: 1000) into the reaction kettle, add 2.09g of toluene diisocyanate after dehydration, and react at 50°C for 4h.

[0048] Add 0.83 g of chain extender (M=Na, x=1) of No. I polysulfonic acid ion group, react at 50°C for 6 hours, cool down to room temperature, and emulsify in water under high-speed shearing to obtain polyurethane emulsion, the highest solid content can be up to 75%.

Embodiment 2

[0050] Add 10 g of polyethylene glycol (molecular weight: 10,000) into the reaction kettle, add 0.26 g of toluene diisocyanate after dehydration, and react at 80°C for 8 hours.

[0051] Add 0.24 g of chain extender (M=Na, x=5) of No. I polysulfonic acid ionic group, react at 80°C for 4 hours, cool down to room temperature, and emulsify in water under high-speed shearing to obtain polyurethane emulsion, the highest solid content can be up to 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com