High-toughness phenolic resin adhesive for abrasive paper, and preparation method and application method thereof

A phenolic resin, high toughness technology, used in non-polymer adhesive additives, aldehyde/ketone condensation polymer adhesives, adhesives, etc., can solve the problem of insufficient bonding strength, poor leveling, poor flexibility, etc. problem, to achieve the effect of low production cost, improved brittleness and service life, and increased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A high-toughness phenolic resin binder for sandpaper, which is prepared by mixing four components A, B, C and D, and the weight ratio of each component of A, B, C and D is 100:20:3:20 ;

[0056] Wherein, A component comprises the raw material of following parts by weight:

[0057] 60 parts of phenolic resin

[0058] Polyurethane 40 parts

[0059] 3 parts of multifunctional amine additives;

[0060] Wherein, component B is water;

[0061] Wherein, C component comprises the raw material of following parts by weight:

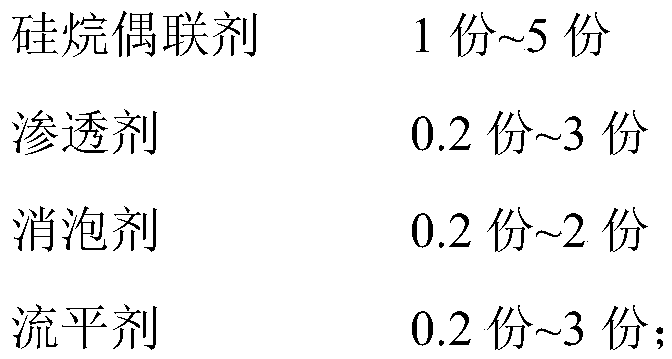

[0062]

[0063] Among them, component D is filler.

[0064] Wherein, the phenolic resin is a thermosetting resole phenolic resin, and in this embodiment, the solid content of the phenolic resin is 70%.

[0065] In this embodiment, polyurethane is a one-component water-based polyurethane emulsion, and in this embodiment, the solid content of polyurethane is 30%.

[0066] In this embodiment, the multifunctional amine additive is Dow AMP-95 multifunctio...

Embodiment 2

[0078] A high-toughness phenolic resin binder for sandpaper, which is prepared by mixing four components A, B, C and D, and the weight ratio of each component of A, B, C and D is 100:1:0.5:5 ;

[0079] Wherein, A component comprises the raw material of following parts by weight:

[0080] 50 parts of phenolic resin

[0081] Polyurethane 30 parts

[0082] 1 part of multifunctional amine additive;

[0083] Wherein, component B is water;

[0084] Wherein, C component comprises the raw material of following parts by weight:

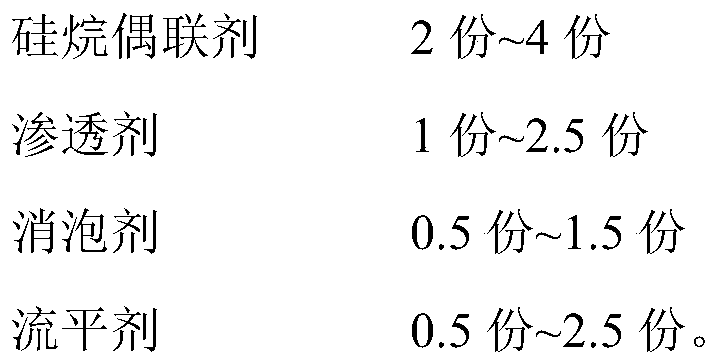

[0085]

[0086] Among them, component D is filler.

[0087] Wherein, the phenolic resin is a thermosetting resole phenolic resin, and in this embodiment, the solid content of the phenolic resin is 60%.

[0088] In this embodiment, polyurethane is a one-component aqueous polyurethane dispersion, and in this embodiment, the solid content of polyurethane is 20%.

[0089] In this example, the multifunctional amine additive is French Solvay AN-130 multifu...

Embodiment 3

[0101] A high-toughness phenolic resin binder for sandpaper, which is prepared by mixing four components A, B, C and D, and the weight ratio of each component of A, B, C and D is 100:40:5:40 ;

[0102] Wherein, A component comprises the raw material of following parts by weight:

[0103] 70 parts of phenolic resin

[0104] Polyurethane 50 parts

[0105] 5 parts of multifunctional amine additives;

[0106] Wherein, component B is water;

[0107] Wherein, C component comprises the raw material of following parts by weight:

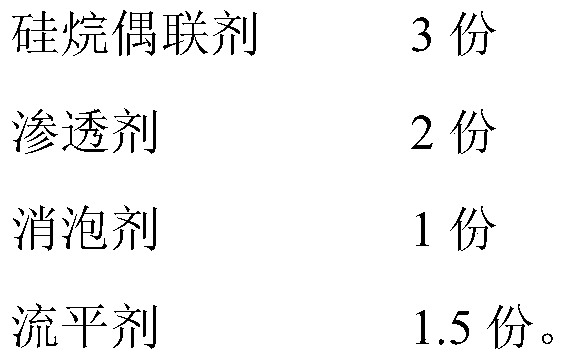

[0108]

[0109] Among them, component D is filler.

[0110] Wherein, the phenolic resin is a thermosetting resole phenolic resin, and in this embodiment, the solid content of the phenolic resin is 80%.

[0111] In this embodiment, polyurethane is a one-component aqueous polyurethane dispersion, and in this embodiment, the solid content of polyurethane is 40%.

[0112] In this example, the multifunctional amine additive is French Solvay AN-130 multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com