Culture production system of scoop frame turning and scooping base liquid arc pasting film for photosynthetic microorganism

A technology of photosynthetic microorganisms and production systems, applied in the field of biological filtration, can solve the problems of doping with floating flocculent turbidity, necrosis of single-cell organisms, and consumption of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

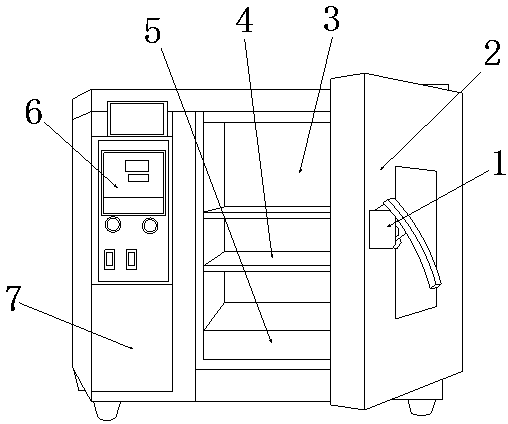

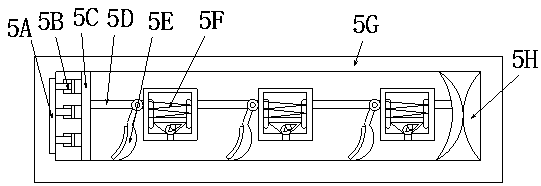

[0033] see Figure 1-Figure 7 , The present invention provides a culture and production system for scooping base liquid arc film with a spoon rack of photosynthetic microorganisms. Bottom groove 5, man-machine interface 6, distribution box shell 7, the bottom groove 5 of the base liquid spoon holder is closely attached to the bottom surface of the inner tank box 3 for lighting, and the flip handle 1 is mechanically connected with the sealing door panel 2 And on the same vertical plane, the sealing door panel 2 is mechanically connected with the light inner tank 3 through hinges, and the lining plate 4 is provided with two and both are inserted into the interior of the light inner tank 3, the said The lining frame plate 4 and the bottom groove 5 of the base liquid spoon frame are parallel to each other, and the man-machine interface 6 is vertically close to the left front side of the distribution box shell 7, and the distribution box shell 7 and the light inner tank 3 Nested i...

Embodiment 2

[0040] see Figure 1-Figure 7 , the present invention provides a kind of culture production system of the spoon rack of photosynthetic microorganisms, scooping base liquid arc film, other aspects are the same as embodiment 1, and the difference is:

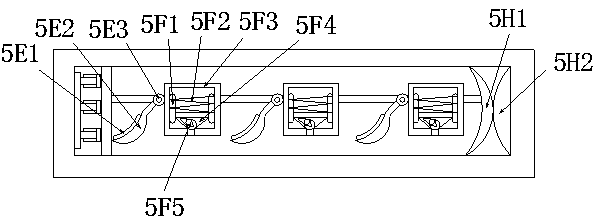

[0041] see image 3 , the surge side carriage 5H is composed of a thin crescent push plate 5H1 and a convex arc to the top pad 5H2, the thin crescent push plate 5H1 and the convex arc to the top pad 5H2 adopt clearance fit, the thin crescent push plate 5H1 is installed Set on the left side of the convex arc top pad 5H2 and on the same vertical plane, through the thin crescent push plate 5H1 and the convex arc top pad 5H2 arc surface tangent point to the top, forming a small amplitude limit swing effect during rolling friction , so that the wave-making effect of the camber surface is less undulating, avoiding excessive splashing into the microbial community, and achieving the effect of guiding the culture medium to provide nutrien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com