Balancing weight type hydraulic pumping unit

A technology of counterweight and pumping unit, applied in the field of beamless hydraulic pumping unit and counterweight hydraulic pumping unit, can solve the problems of high energy consumption and poor stability of the frame, and reduce the volume and impact force. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

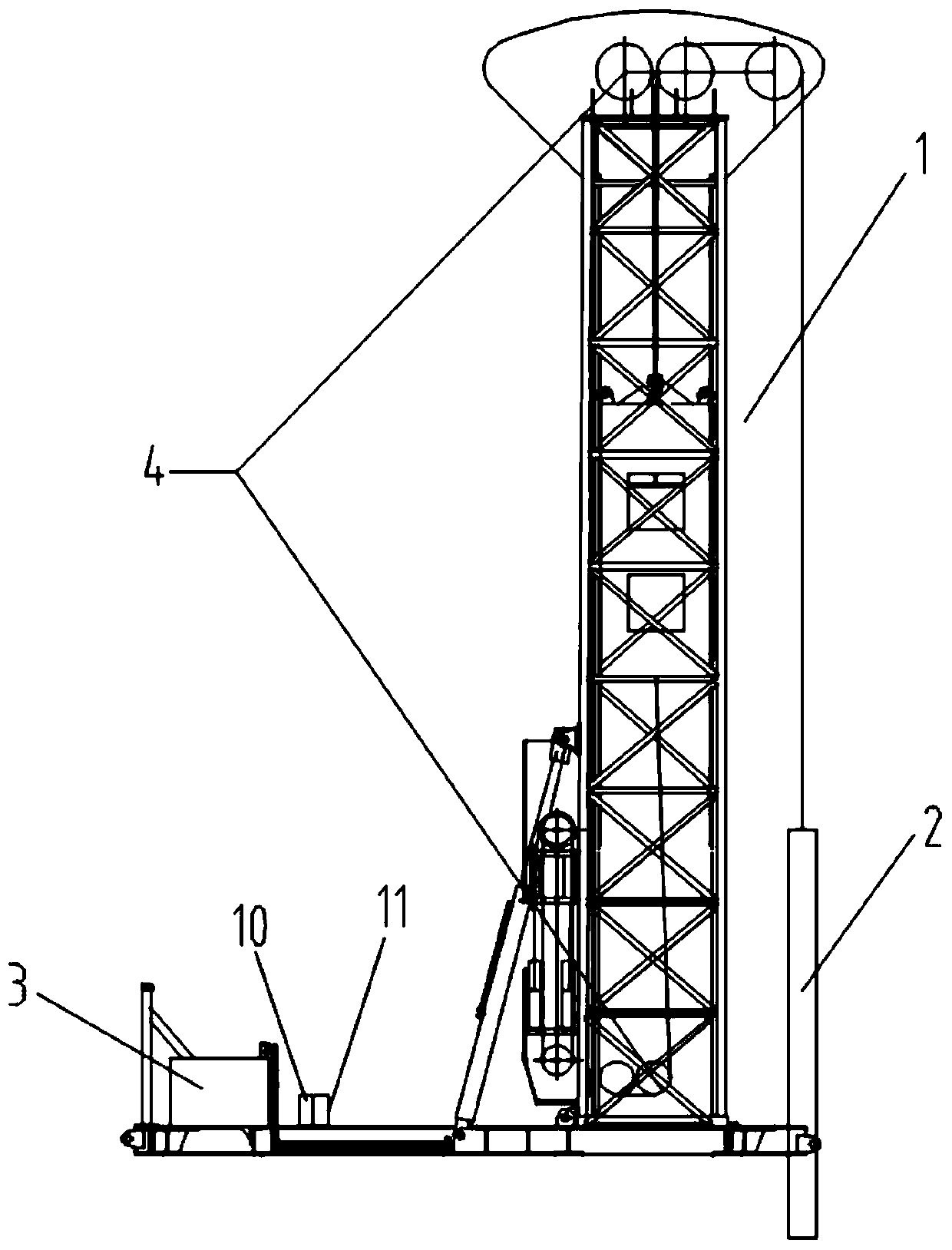

[0039] Such as figure 1 As shown, the counterweight hydraulic pumping unit of the first embodiment of the present invention includes a tower frame 1, a sucker rod 2, a hydraulic constant power power system 3, a stroke amplification system 4, an electronic monitoring and alarm system 10, an electric control system 11, the hydraulic constant power power system includes an oil cylinder to provide power for the sucker rod 1; an electric control system 11 and a monitoring and alarm system 10 are installed on the base below the tower frame, and the top of the tower frame is fixedly equipped with Crane.

[0040] Wherein, the weight of the counterweight is greater than the maximum suspension point load of the sucker rod, and the weight of the counterweight is preferably 1.05 times of the maximum suspension point load of the sucker rod.

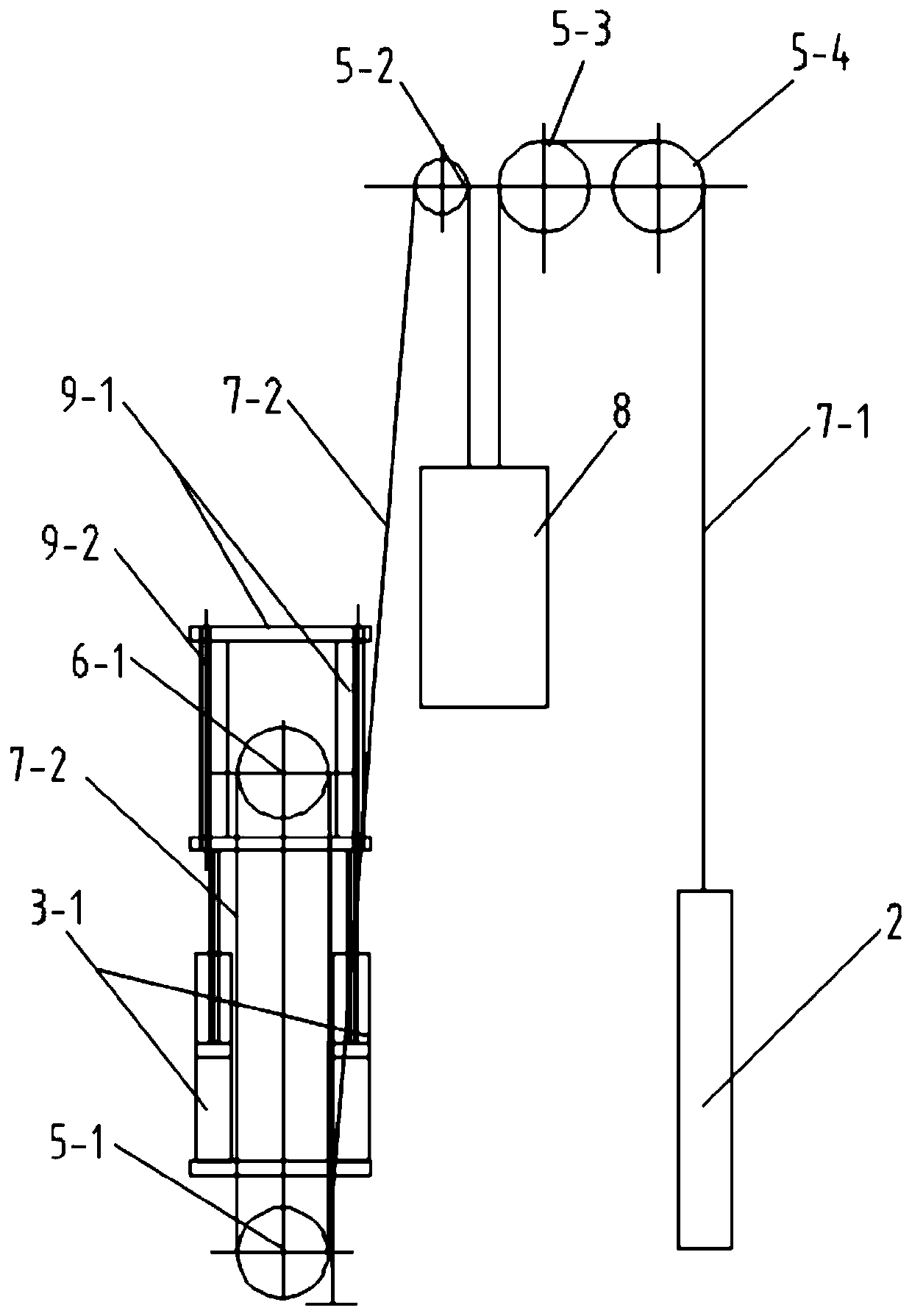

[0041] Such as figure 2 As shown, the stroke amplification system includes a fixed pulley block, a movable pulley block, a lifting device, a count...

Embodiment 2

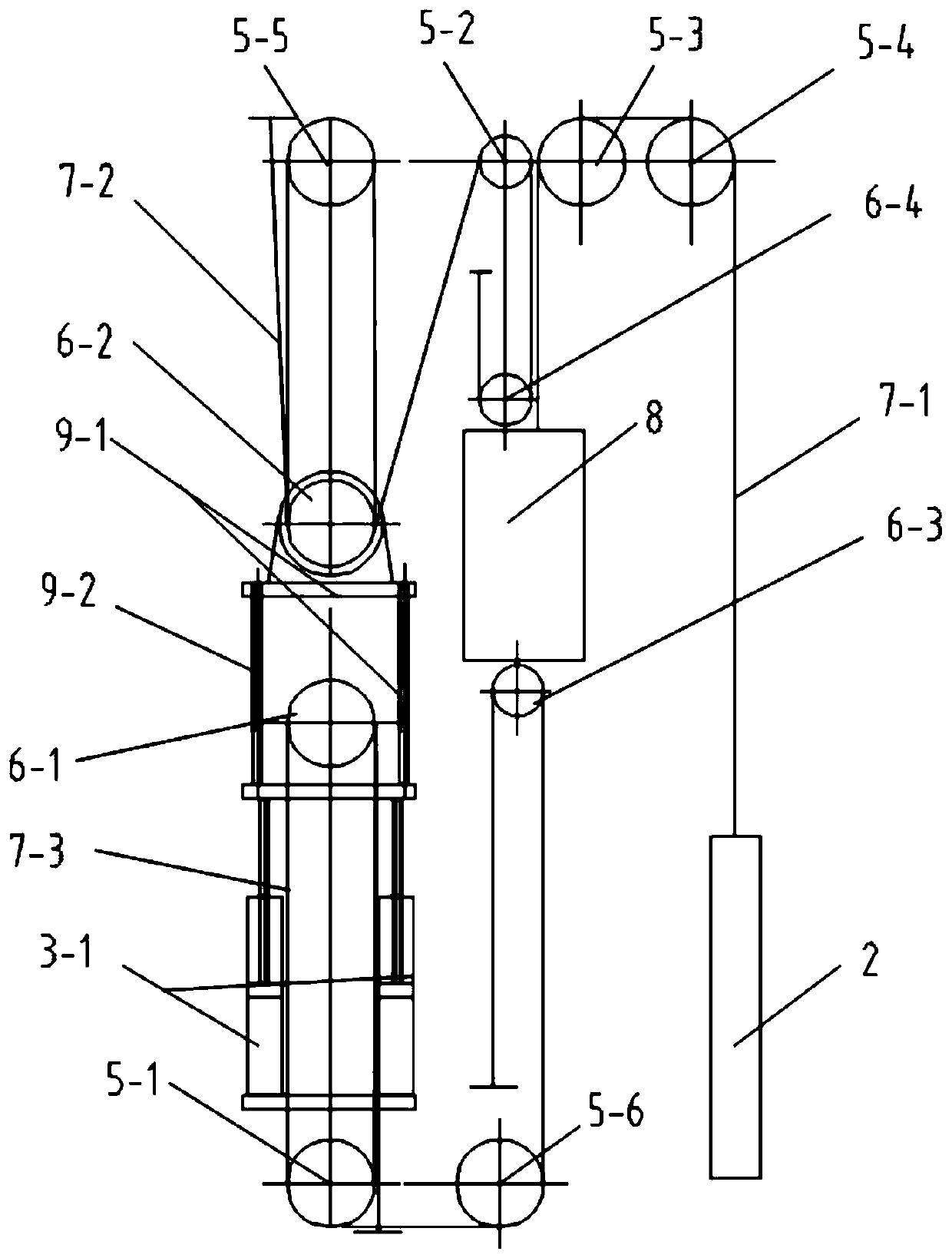

[0054] The difference between the counterweight hydraulic pumping unit of the second embodiment of the present invention and the embodiment 1 lies in the formation of an amplification system.

[0055] Such as image 3 As shown, the stroke amplification system includes a fixed pulley block, a movable pulley block, a lifting device, a counterweight and a steel wire rope group; the lifting device is connected to the output end of the oil cylinder, and the steel wire rope group is connected to the lifting device, the fixed pulley block, The counterweight, the movable pulley block, and the end are fixedly connected with the sucker rod, and the short stroke of the oil cylinder is amplified into the long stroke of the sucker rod.

[0056] Specifically: the fixed pulley block has six fixed pulleys, which are respectively the first fixed pulley 5-1, the second fixed pulley 5-2, the third fixed pulley 5-3, the fourth fixed pulley 5-4, and the fifth fixed pulley. Pulley 5-5, the sixth f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com