Industrial waste treatment device for environmental protection

A technology for industrial waste and treatment devices, applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of reducing the quality of waste incineration, insufficient waste incineration, etc. The effect of improving incineration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

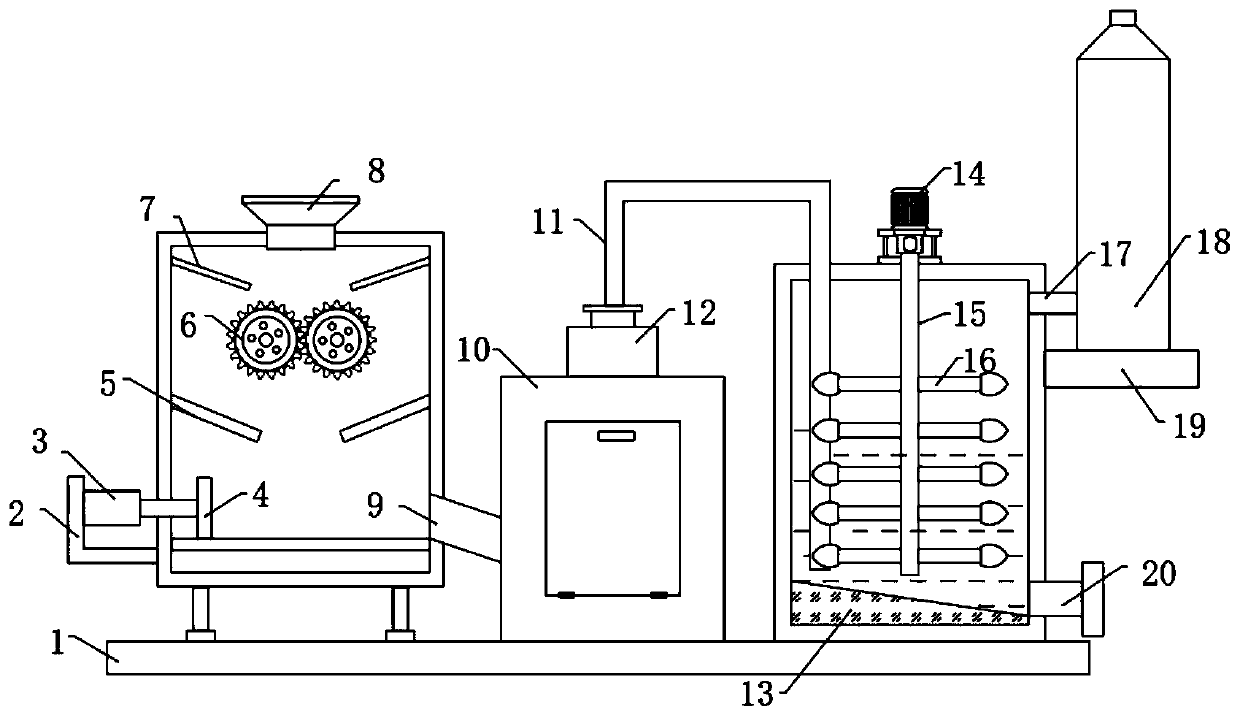

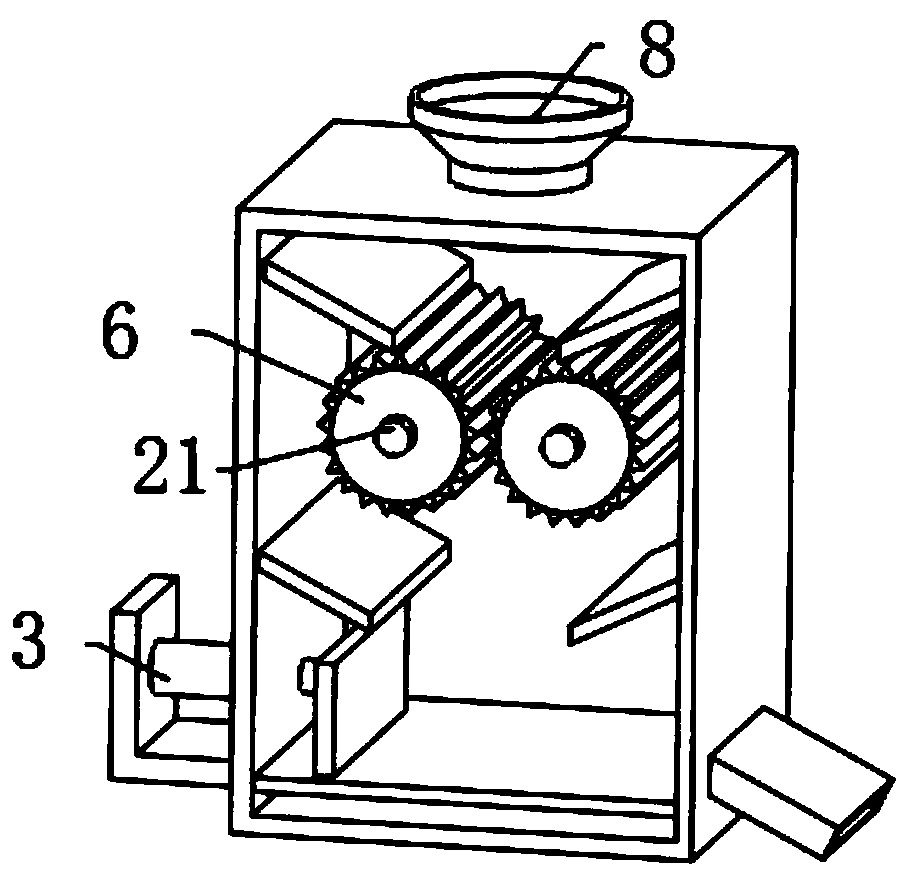

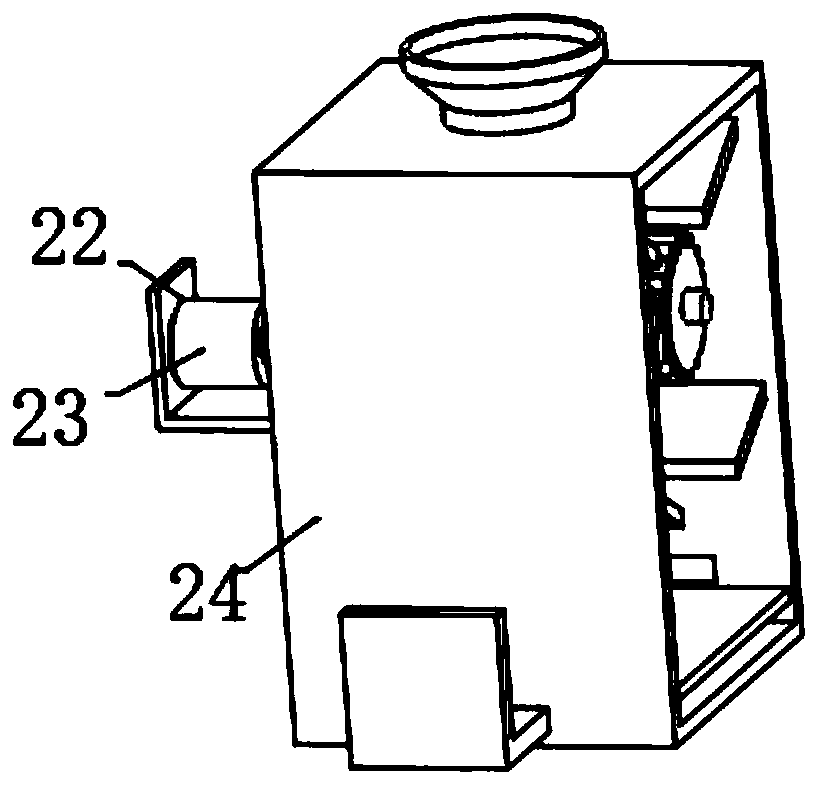

[0029] refer to Figure 1-4 , an industrial waste disposal device for environmental protection, comprising a bottom plate 1, a crushing box 24, an incinerator 10 and a mixing box are fixed on the top outer wall of the bottom plate 1 by screws, and a second connecting plate is fixed on one side of the crushing box 24 by screws 22. The outer wall of one side of the second connecting plate 22 is fixed with a second motor 23 by screws, and the inner wall of the crushing box 24 is connected with two second rotating rods 21 through bearings, and the output shaft of the second motor 23 is connected by a coupling On the outer wall of one of the second rotating rods 21, the outer wall of one side of the crushing box 24 is fixed with a pusher mechanism by screws, and the first inclined plate 5 and the second inclined plate 7 are welded on both sides of the inner wall of the crushing box 24, and the mixing box The top outer wall of the mixing box is fixed with a stirring mechanism by scr...

Embodiment 2

[0033] refer to Figure 5 , an industrial waste treatment device for environmental protection, including, and also including an exhaust fan 27 fixed to the outer wall of the incinerator 10 by screws, the output end of the exhaust fan 27 and the top inner wall of the incinerator 10 are connected by a flange with the same first Two conduits 28 .

[0034] Connect the equipment to the power supply, connect the hydraulic rod 3 to the hydraulic system, put industrial waste from the feed port 8 into the crushing box 24, turn on the second motor 23, and the second motor 23 drives the second rotary rod 21 to rotate and then crush The roller 6 crushes the industrial waste, adjusts the length of the hydraulic rod 3, so that the push plate 4 pushes the crushed waste to the chute 9, and the waste enters the incinerator 10 for incineration, and the waste gas generated by the incineration passes through the purifier 12 and the air duct 11 Enter the mixing box, turn on the first motor 14, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com