Permanent magnet brake for adjusting magnetic field intensity

A technology of magnetic field strength and permanent magnets, applied in the direction of permanent magnet clutches/brakes, electrical components, electromechanical devices, etc., can solve the problems of damage to the car's own parts, reduce the service life of parts, and the speed difference between the inner and outer rings cannot be balanced. The effect of reducing vibration, reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

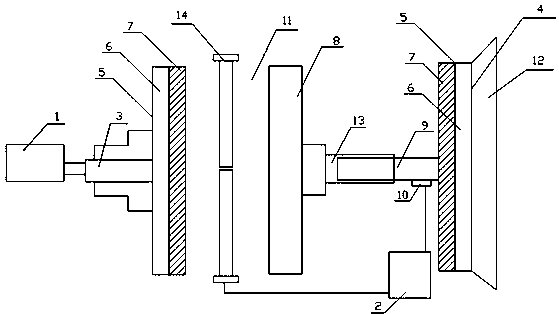

[0020] Further illustrate the present invention in conjunction with accompanying drawing.

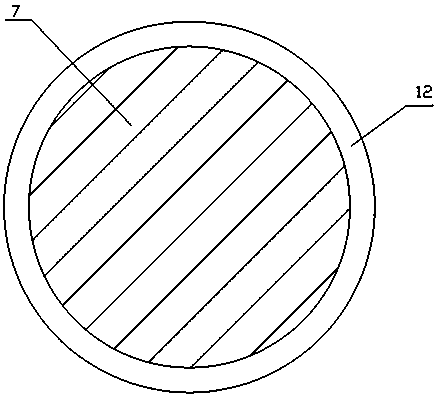

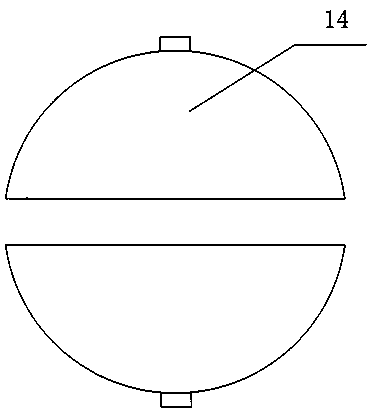

[0021] like figure 1 and figure 2 , the motor 1 is connected with the motor shaft 3, the motor shaft 3 is connected with the conductor rotor 5, the conductor rotor 5 is composed of an outer steel body 6 and an inner copper conductor 7; a permanent magnet 8 is arranged opposite to the conductor rotor 5, and the permanent magnet 8 is connected with the drive shaft 9 is connected through the coaxial sleeve 13, and the drive shaft 9 is connected with the load 4. The load 4 is composed of another set of conductor rotor 5 and hub 12; an air gap 11 is formed between the conductor rotor 5 and the permanent magnet 8; the spline 10 is connected with the drive shaft 9; one end of the coaxial sleeve 13 is connected with the permanent magnet 8, and the other One end is connected with the drive shaft 9; the electronic control system 2 is connected with the magnetic isolation component 14 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com