Novel cold-resistant oil-resistant flame-retardant antistatic conveyor belt

A technology for flame retardant and antistatic conveyor belts, which is applied in the field of cold-resistant, flame-retardant, oil-resistant, and antistatic conveyor belts. Electrostatic failure, avoiding the effect of accelerated damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

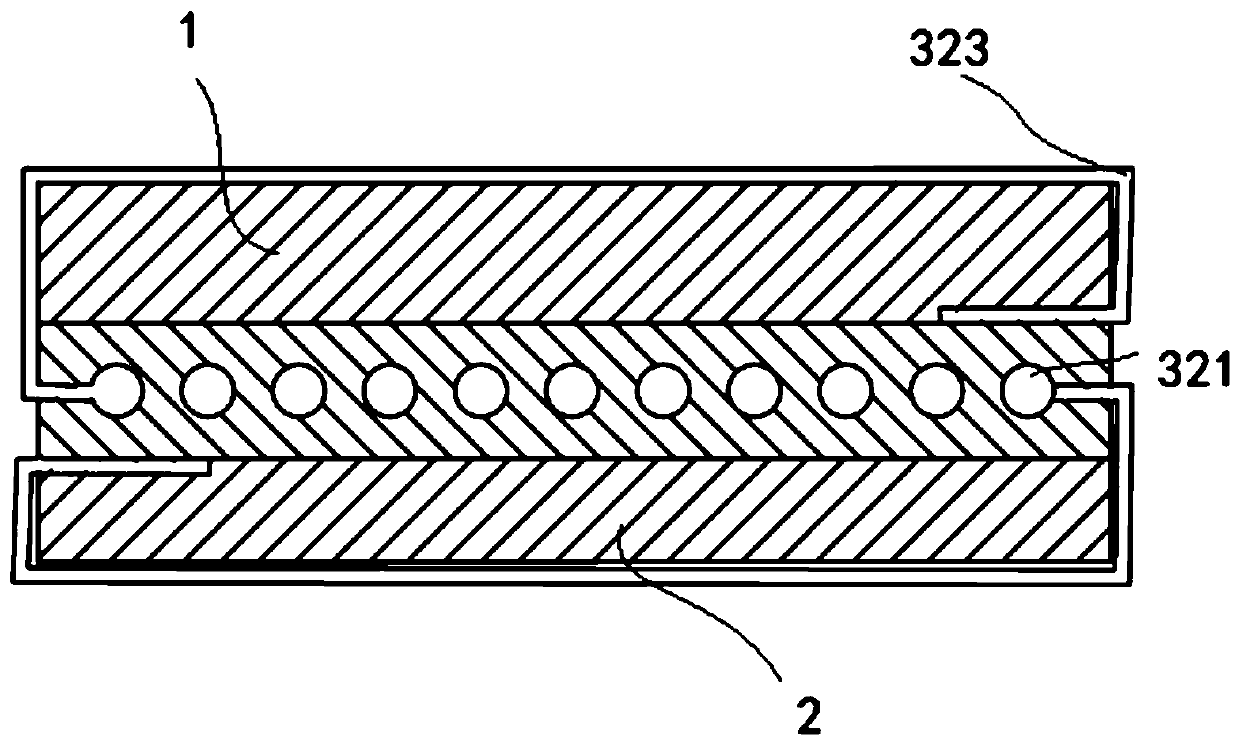

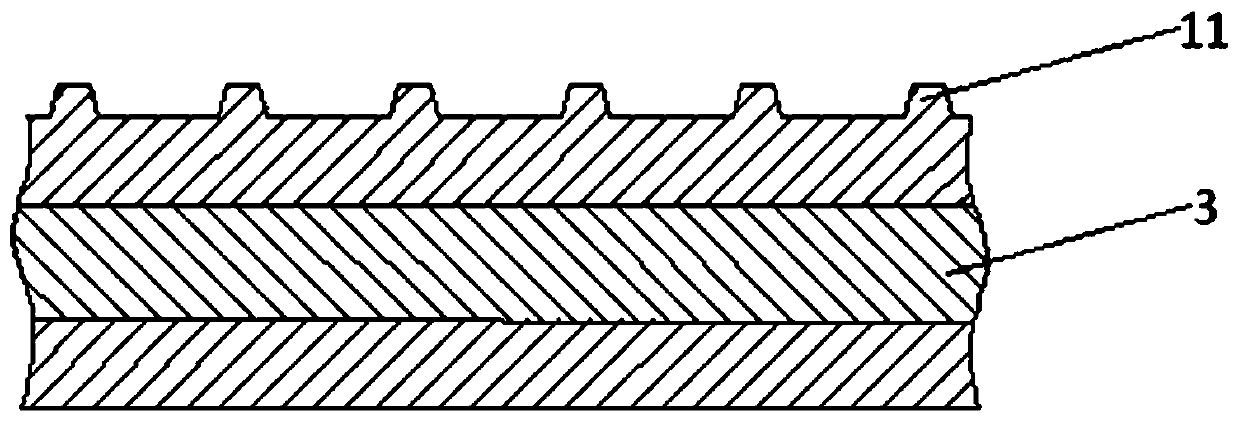

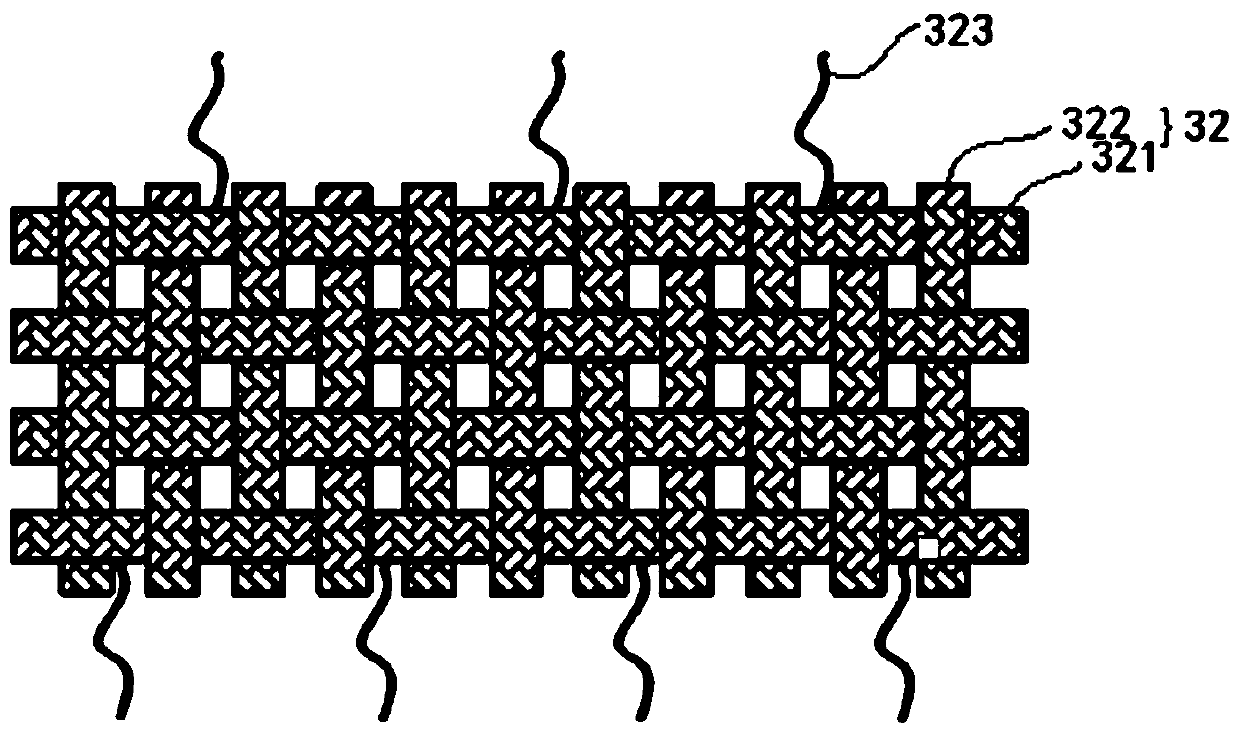

[0032] combine Figure 1-3 , the embodiment of the present invention discloses a new type of cold-resistant, oil-resistant, flame-retardant and antistatic conveyor belt, comprising: an upper cover rubber layer 1, a lower cover rubber layer 2 and a skeleton layer 3, and the upper surface of the upper cover rubber layer 1 is provided with anti-skid protrusions Strip 11, the upper cover rubber layer 1 and the anti-skid raised strip 11 are integrally formed, the skeleton layer 3 is located between the upper cover rubber layer 1 and the lower cover rubber layer 2, and the skeleton layer 3 is mainly composed of adhesive core rubber 31 and steel wire mesh 32 , the steel wire mesh 32 is evenly distributed between the adhesive core rubber 31 .

[0033] In the above embodiments, the cross section of the anti-skid raised strip 11 is trapezoidal, and in other embodiments, the anti-slip raised strip 11 can also be configured as a wavy pattern.

[0034] In the above-mentioned embodiment, t...

Embodiment 2

[0038] The cover rubber in the upper cover rubber layer and the lower cover rubber layer is mainly blended with nitrile rubber, chlorosulfonated polyethylene rubber and butadiene rubber. The formula is by weight: 30 parts of nitrile rubber, chlorosulfonated polyethylene 20 parts of rubber, 20 parts of butadiene rubber, 0.5 parts of magnesium oxide, 1 part of stearic acid, 3 parts of coumarone resin, 3 parts of anti-aging agent, 40 parts of reinforcing filler, 5 parts of cold-resistant plasticizer, liquid flame retardant 9 parts, 12 parts of solid flame retardant, 0.3 parts of vulcanizing agent, 0.8 parts of accelerator, 3 parts of indirect zinc oxide.

[0039] Specifically, from 1 part of antiaging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer (4010NA) and 1 part of antiaging agent N-isopropyl-N'-phenylterephthalene The anti-aging agent composed of amine (RD) is 3 parts in total.

[0040] Specifically, carbon black is selected as the reinforcing filler, and the reinforci...

Embodiment 3

[0044]The cover rubber in the upper cover rubber layer and the lower cover rubber layer is mainly blended with nitrile rubber, chlorosulfonated polyethylene rubber and butadiene rubber. The formula is by weight: 50 parts of nitrile rubber, chlorosulfonated polyethylene 35 parts of rubber, 30 parts of butadiene rubber, 5 parts of magnesium oxide, 3 parts of stearic acid, 6.5 parts of coumarone resin, 6.5 parts of anti-aging agent, 70 parts of reinforcing filler, 12.5 parts of cold-resistant plasticizer, liquid flame retardant 29.5 parts, 26 parts of solid flame retardant, 2.7 parts of vulcanizing agent, 1.4 parts of accelerator, 6.5 parts of indirect zinc oxide.

[0045] Specifically, 3.5 parts of anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer (4010NA) and 3 parts of anti-aging agent N-isopropyl-N'-phenylterephthalene A total of 6.5 parts of antioxidants composed of amines (RD).

[0046] Specifically, carbon black is selected as the reinforcing filler, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com