Capillary mold oil for aluminum alloy casting crystallizer and preparation method of aluminum alloy casting capillary mold oil

A crystallizer and capillary technology, which is applied in the field of aluminum alloy casting mold capillary release oil and its preparation, can solve problems such as poor performance, large mold damage, and smoke, so as to reduce coking and residual carbon and improve surface quality , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

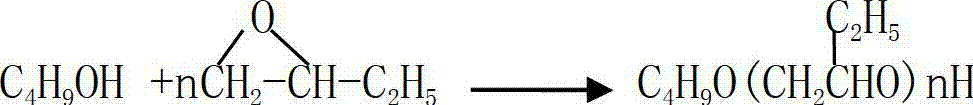

Method used

Image

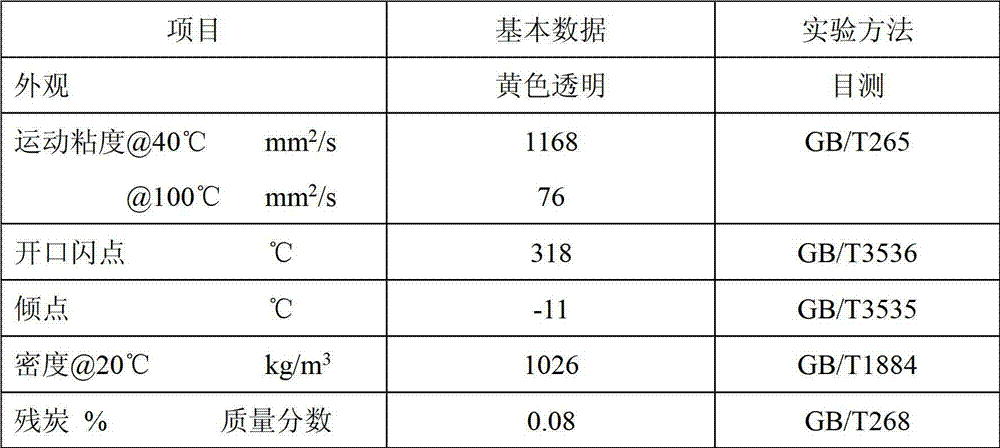

Examples

Embodiment 1

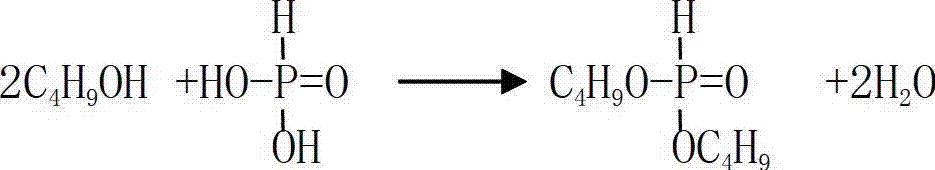

[0028] Step 1: Feed 148.24kg (2000mol) of n-butanol and 82kg (1000mol) of phosphorous acid into the reaction kettle, fill it with nitrogen protection, stir and heat to 130°C, keep it warm for 4 hours, and evaporate the water under reduced pressure to obtain dibutanesulfide Phosphate ester 198.2kg (1000mol);

[0029] Step 2: Add 74.12kg (1000mol) of n-butanol and 15kg of potassium hydroxide into the polymerization kettle cooled by ice-salt water circulation at about 0°C and stir, then pass nitrogen into the polymerization kettle to convert the air in the kettle, when the nitrogen in the polymerization kettle While maintaining the positive pressure, push 1442.2kg (20000mol) of butylene oxide into the polymerization kettle with a nitrogen feed tank, while stirring to raise the temperature to 110-120°C, and adjust the pressure to 0.25MPa. The polymer is extruded to obtain 1531.32kg of polyoxybutylene monobutyl ether (containing potassium hydroxide).

[0030] Step 3: Take 5 kg of ...

Embodiment 2

[0034] Step 1: Add 74.12kg (1000mol) of n-butanol and 4kg of potassium hydroxide into the polymerization kettle cooled by ice-salt water circulation at about 0°C and stir, then pass nitrogen into the polymerization kettle to convert the air in the kettle, when the nitrogen in the polymerization kettle While maintaining the positive pressure, push 721.1kg (10000mol) of butylene oxide into the polymerization kettle with a nitrogen feed tank, while stirring to raise the temperature to 120°C, and adjust the pressure to 0.35MPa. The extruded product is polyoxybutylene monobutyl ether 799.22kg (containing potassium hydroxide).

[0035] Step 2: Feed 148.24kg (2000mol) of n-butanol and 82kg (1000mol) of phosphorous acid into the reaction kettle, fill it with nitrogen protection, stir and heat to 140°C, keep it warm for 3 hours, and evaporate the water under reduced pressure to obtain dibutanesulfide Phosphate ester 198.2kg (1000mol);

[0036] Step 3: Take 3 kg of dibutane phosphite g...

Embodiment 3

[0040] Step 1: Feed 148.24kg (2000mol) of n-butanol and 82kg (1000mol) of phosphorous acid into the reaction kettle, fill it with nitrogen protection, stir and heat to 135°C, keep it warm for 3.5 hours, and steam off the water under reduced pressure to obtain dibutanesulfide Phosphate ester 198.2kg (1000mol);

[0041] Step 2: Add 74.12kg (1000mol) of n-butanol and 6kg of potassium hydroxide into the polymerization kettle cooled by ice-salt water circulation at about 0°C and stir, then pass nitrogen into the polymerization kettle to convert the air in the kettle, when the nitrogen in the polymerization kettle While maintaining the positive pressure, push 1081.5kg (15000mol) butylene oxide into the polymerization kettle with a nitrogen feed tank, while stirring to raise the temperature to 110-120°C, and adjust the pressure to 0.3MPa. The extruded polymer is polyoxybutylene monobutyl ether 1161.62kg (containing potassium hydroxide).

[0042] Step 3: Take 4 kg of dibutane phosphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com