Halogen-free and non-phosphorus flame-retardant epoxy resin composition and preparation method thereof

A technology of epoxy resin and manufacturing method, which is applied in the field of environmentally friendly flame-retardant materials, can solve the problems of reducing the insulation and drilling performance of PCB boards, heat resistance, insufficient moisture resistance, and insignificant improvement of moisture resistance, etc., to achieve improved resistance Effects of peel performance, smoke reduction, high chemical bond energy, and thermo-oxygen stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

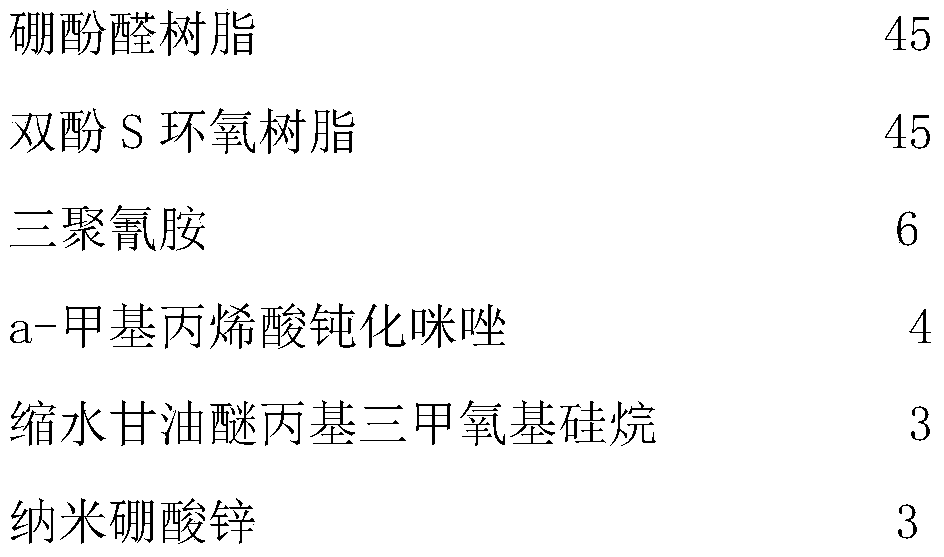

[0018] The halogen-free and phosphorus-free flame-retardant epoxy resin composition of the present invention has the following weight and component ratios:

[0019]

[0020] The above-mentioned components are dissolved in acetone or absolute ethanol solvent, and after being uniform and transparent, they are mixed to form a halogen-free and phosphorus-free flame-retardant epoxy resin composition.

[0021] The a-methacrylic acid deactivated imidazole is generated by the reaction of equal chemical equivalents of a-methacrylic acid and 2-ethyl, 4-methylimidazole.

[0022] The above-mentioned halogen-free and phosphorus-free flame-retardant epoxy resin composition is impregnated with 0.05-0.2mm thick E-glass fiber plain weave cloth, and acetone or absolute ethanol solvent is removed to make E-glass cloth / epoxy resin prepreg. After the prepregs are stacked in multiple layers, they are placed in a steel mold and pressed on a flat hot press to obtain an E-glass cloth / halogen-free a...

Embodiment 2

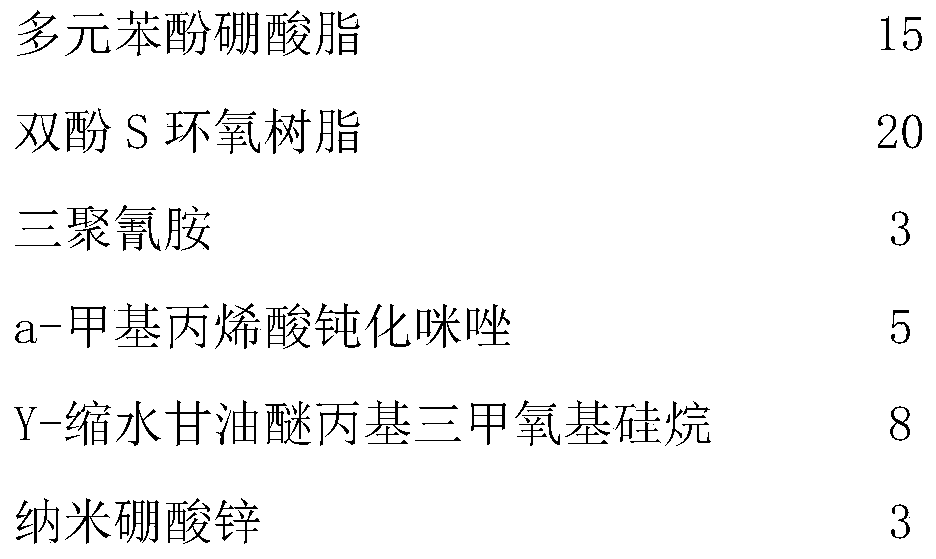

[0024] The halogen-free and phosphorus-free flame-retardant epoxy resin composition of the present invention has the following weight and component ratios:

[0025]

[0026] The above-mentioned components are dissolved in acetone or absolute ethanol solvent, and after being uniform and transparent, they are mixed to form a halogen-free and phosphorus-free flame-retardant epoxy resin composition.

[0027] The above-mentioned halogen-free and phosphorus-free flame-retardant epoxy resin composition is impregnated with 0.05-0.2mm thick E-glass fiber plain weave cloth, and acetone or absolute ethanol solvent is removed to make E-glass cloth / epoxy resin prepreg. After the prepregs are stacked in multiple layers, they are placed in a steel mold and pressed on a flat hot press to obtain an E-glass cloth / halogen-free and phosphorus-free flame-retardant epoxy resin laminate; use the same process as above, use copper foil and E - Glass cloth / halogen-free and phosphorus-free flame-reta...

Embodiment 3

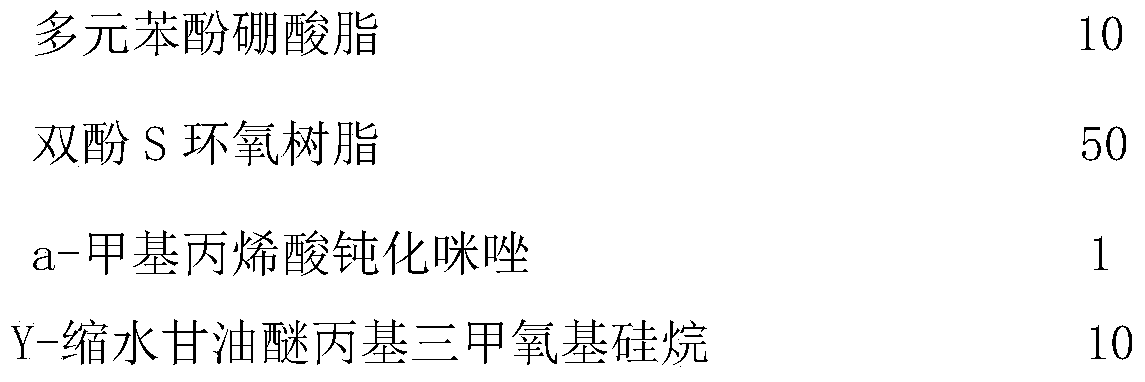

[0029] The halogen-free and phosphorus-free flame-retardant epoxy resin composition of the present invention has the following weight and component ratios:

[0030]

[0031] The above-mentioned components are dissolved in acetone or absolute ethanol solvent, and after being uniform and transparent, they are mixed to form a halogen-free and phosphorus-free flame-retardant epoxy resin composition.

[0032] The a-methacrylic acid deactivated imidazole is generated by the reaction of equivalent stoichiometric a-methacrylic acid and 2-ethyl, 4-methylimidazole.

[0033] The above-mentioned halogen-free and phosphorus-free flame-retardant epoxy resin composition is impregnated with 0.05-0.2mm thick E-glass fiber plain weave cloth, and acetone or absolute ethanol solvent is removed to make E-glass cloth / epoxy resin prepreg. After the prepregs are stacked in multiple layers, they are placed in a steel mold and pressed on a flat hot press to obtain an E-glass cloth / halogen-free and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com