Spark-oil-resistant rubber protective cover and preparation method thereof

A rubber protection and spark oil technology, applied in the field of electric spark equipment, can solve the problems of easy combustion of the shield, causing accidents, and the shield is not resistant to the dissolution and corrosion of electric spark oil, and achieves good flame resistance and good resistance to electric spark oil. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

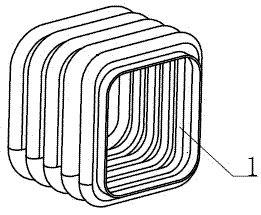

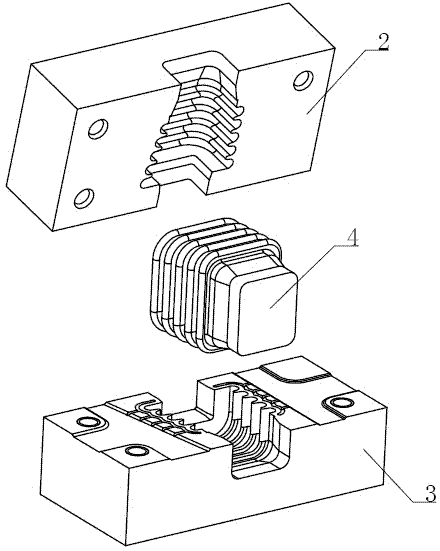

Image

Examples

Embodiment 1

[0026] The anti-spark oil rubber protective cover is made of the following raw materials in parts by weight: 50 parts of nitrile rubber 220S, 30 parts of neoprene rubber CR322, 7 parts of carbon black N330, 4 parts of DOP, 0.5 parts of stearic acid, and 0.5 parts of paraffin , 0.5 parts of anti-aging agent RD, 0.5 parts of 4010Na, 3 parts of light magnesium oxide, 0.2 parts of sulfur, 0.6 parts of DM, 0.6 parts of TMTD, 2 parts of nano ZnO, 0.1 parts of NA-22, and 0.5 parts of DCP.

[0027] The preparation method of above-mentioned anti-spark oil rubber protective cover, comprises the following steps:

[0028] (1) Ingredients: Weigh the above-mentioned raw materials in parts by weight respectively for later use;

[0029] (2) Mastication: put nitrile rubber 220S and neoprene CR322 into the internal mixer for 3-5 minutes, until the two kinds of rubber are fully fused;

[0030] (3) Mixing: In the first step, carbon black N330, plasticizer DOP, stearic acid, paraffin, anti-aging ...

Embodiment 2

[0036] The anti-spark oil rubber protective cover is made of the following raw materials in parts by weight: 60 parts of nitrile rubber 220S, 40 parts of neoprene rubber CR322, 10 parts of carbon black N330, 5 parts of DOP, 1 part of stearic acid, and 1 part of paraffin wax , 1 part of anti-aging agent RD, 1 part of 4010Na, 4 parts of light magnesium oxide, 0.3 parts of sulfur, 0.8 parts of DM, 0.8 parts of TMTD, 2.5 parts of nano-ZnO, 0.3 parts of NA-22, and 1 part of DCP.

[0037] The preparation method of above-mentioned anti-spark oil rubber protective cover, comprises the following steps:

[0038] (1) Ingredients: Weigh the above-mentioned raw materials in parts by weight respectively for later use;

[0039] (2) Mastication: put nitrile rubber 220S and neoprene CR322 into the internal mixer for 3-5 minutes, until the two kinds of rubber are fully fused;

[0040] (3) Mixing: In the first step, carbon black N330, plasticizer DOP, stearic acid, paraffin, anti-aging agent RD, ...

Embodiment 3

[0046] The spark oil resistant rubber protective cover is made of the following raw materials in parts by weight: 70 parts of nitrile rubber 220S, 50 parts of neoprene rubber CR322, 12 parts of carbon black N330, 6 parts of DOP, 1.5 parts of stearic acid, and 1.5 parts of paraffin , 1.5 parts of anti-aging agent RD, 1.5 parts of 4010Na, 6 parts of light magnesium oxide, 0.4 parts of sulfur, 1 part of DM, 1 part of TMTD, 3 parts of nano ZnO, 0.5 parts of NA-22, and 1.5 parts of DCP.

[0047] The preparation method of above-mentioned anti-spark oil rubber protective cover, comprises the following steps:

[0048] (1) Ingredients: Weigh the above-mentioned raw materials in parts by weight respectively for later use;

[0049] (2) Mastication: put nitrile rubber 220S and neoprene CR322 into the internal mixer for 3-5 minutes, until the two kinds of rubber are fully fused;

[0050] (3) Mixing: In the first step, carbon black N330, plasticizer DOP, stearic acid, paraffin, anti-aging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com