Low-gloss and good-appearance polypropylene composite material for automotive interiors and preparation method thereof

A technology for composite materials and automotive interiors, applied in the field of polymer modification, can solve the problems of reducing the gloss of polypropylene materials, strong light reflection, and surface gloss reduction, so as to improve surface roughness, enhance diffuse reflection, reduce The effect of gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

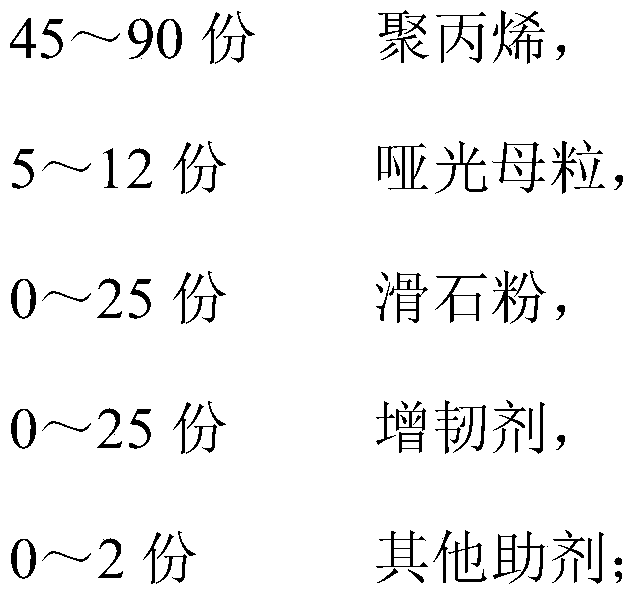

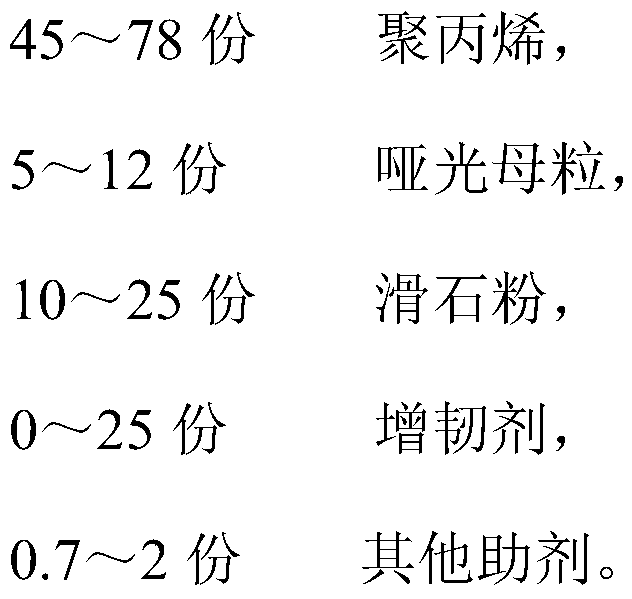

Method used

Image

Examples

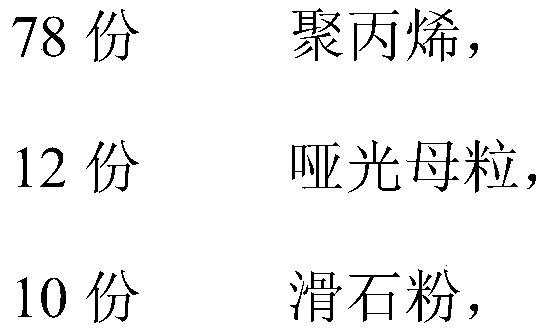

Embodiment 1

[0036] This embodiment provides a low-gloss, good-looking polypropylene composite material for automotive interiors (see Table 1 for the raw material formula) and a preparation method thereof.

[0037] The preparation method is as follows:

[0038] (1) 30 parts of HDPE powder and 3 parts of diethylpropylbenzene peroxide are mixed evenly, added to the side feeding tank, 70 parts of HDPE main feed is added, the extrusion temperature is set at 160 ° C, and the extrusion reaction is carried out to prepare the dumb Optical masterbatch 1;

[0039] (2) Take the material according to the formulas of the embodiments and comparative examples in Table 1, and use high-speed mixing in a high-speed mixer for 4 to 8 minutes; the uniformly mixed mixture is extruded and granulated by a twin-screw extruder; each section of the extruder is set The temperature is 180°C, the screw speed is 450r / min, and the vacuum degree is greater than 0.06MPa.

Embodiment 2

[0041] This embodiment provides a low-gloss, good-looking polypropylene composite material for automotive interiors (see Table 1 for the raw material formula) and a preparation method thereof.

[0042] The preparation method is as follows:

[0043] (1) 20 parts of HDPE powder and 0.5 parts of diethylpropylbenzene peroxide are mixed evenly, added to the side feeding tank, 80 parts of HDPE main feed is added, the extrusion temperature is set at 170 ° C, and the extrusion reaction is carried out to prepare a dumb Optical masterbatch 1;

[0044] (2) Take the material according to the formulas of the embodiments and comparative examples in Table 1, and use high-speed mixing in a high-speed mixer for 4 to 8 minutes; the uniformly mixed mixture is extruded and granulated by a twin-screw extruder; each section of the extruder is set The temperature is 190°C, the screw speed is 480r / min, and the vacuum degree is greater than 0.06MPa.

Embodiment 3

[0046] This embodiment provides a low-gloss, good-looking polypropylene composite material for automotive interiors (see Table 1 for the raw material formula) and a preparation method thereof.

[0047] The preparation method is as follows:

[0048] (1) 30 parts of HDPE powder and 2 parts of diethylpropylbenzene peroxide are mixed evenly, added to the side feeding tank, 70 parts of HDPE main feed is added, the extrusion temperature is set at 160 °C, and the extrusion reaction is carried out to prepare the dumb Optical masterbatch 1;

[0049] (2) Take the material according to the formulas of the embodiments and comparative examples in Table 1, and use high-speed mixing in a high-speed mixer for 4 to 8 minutes; the uniformly mixed mixture is extruded and granulated by a twin-screw extruder; each section of the extruder is set The temperature is 200°C, the screw speed is 500r / min, and the vacuum degree is greater than 0.06MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com