Stone color spot removing method and stone color spot removing agent

A scavenger and stain removal technology, which is applied in the direction of stone processing tools, stone processing equipment, chemical instruments and methods, etc., can solve the problems of short cleaning agent action time, long cleaning process, and unstable cleaning effect, so as to avoid oxidants Flowing, stable cleaning process, and thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 2

[0027] With the mass ratio of 100:35, 200 mesh diatomite and bentonite are mixed into powdery carrier, then with the mass ratio of 100:40, the powdery carrier is mixed with sodium percarbonate powder (active oxygen content 13%), then Measuring, dispensing and packaging to make the finished product of stone stain remover. When in use, mix stone stain removal powder with water at a mass ratio of 1:2.5-4 and stir to form a paste (or add water to stone stain remover and stir to form a paste), and apply it on the stain pollution on the stone surface.

preparation example 3

[0029] Mix 200-mesh bentonite and 300-mesh aluminum magnesium silicate into a powder carrier at a mass ratio of 1:1, and then mix the powdered carrier with sodium percarbonate powder (13% active oxygen content) at a mass ratio of 100:45 Evenly, then metering, subpackaging and packaging to make the finished product of stone stain remover. When in use, mix stone stain removal powder with water at a mass ratio of 1:2.2-4 and stir to form a paste (or add water to stone stain remover and stir to form a paste), and apply it on the stain pollution on the stone surface.

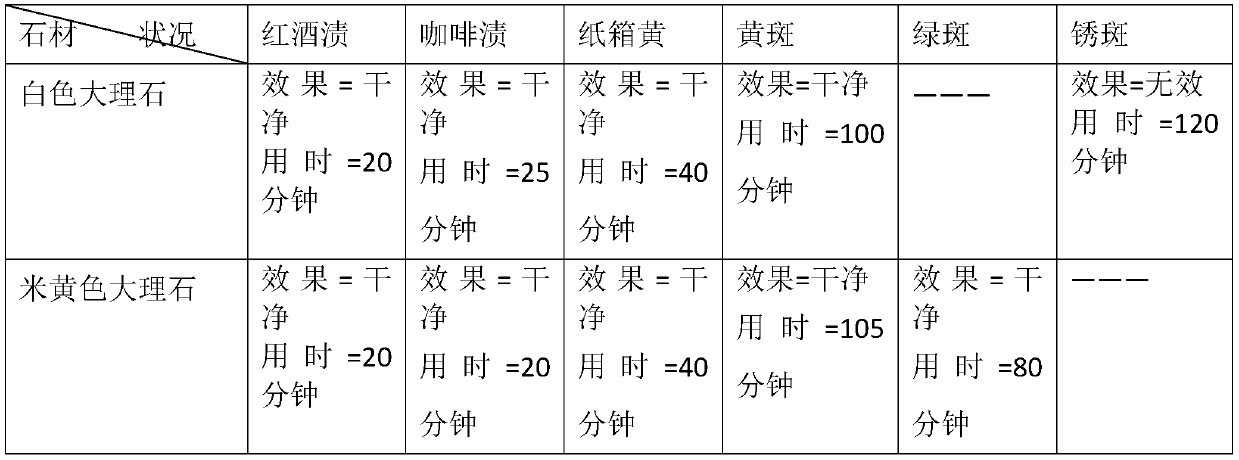

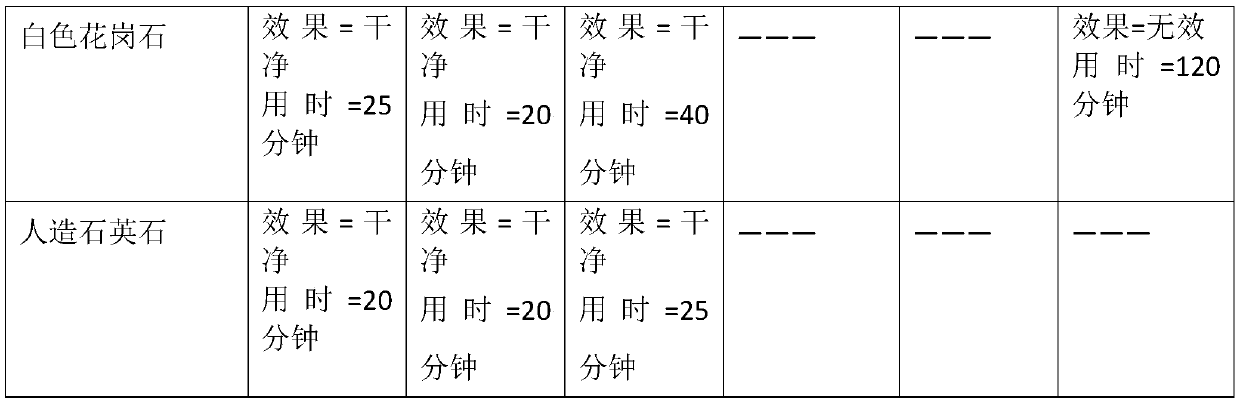

[0030] The following test examples are aimed at the common red wine stains, coffee stains, carton yellow (carton pollution traces), stains (iron-free yellow or brown or green that come out from the inside of the stone under wet conditions) on the surface of architectural decorative stones. stains) and rust spots, and the cleaning effect was compared with common stone types as substrates.

[0031] Clearing method emb...

Embodiment 2

[0038] Wear a protective mask, mix 200 mesh diatomaceous earth and aluminum magnesium silicate powder with a mass ratio of 100:30 to obtain a powdery carrier at the stone stain removal site, and mix the powdery carrier with sodium percarbonate (active oxidation content 13%) ) according to the mass ratio of 1:0.4 mixed to clean the powder mixture. Then mix and stir the cleaning powder mixture and water according to the mass ratio of 1:3.2 to form a paste (the ratio of powder mixture and water can be measured or not, just add water and mix to form a paste).

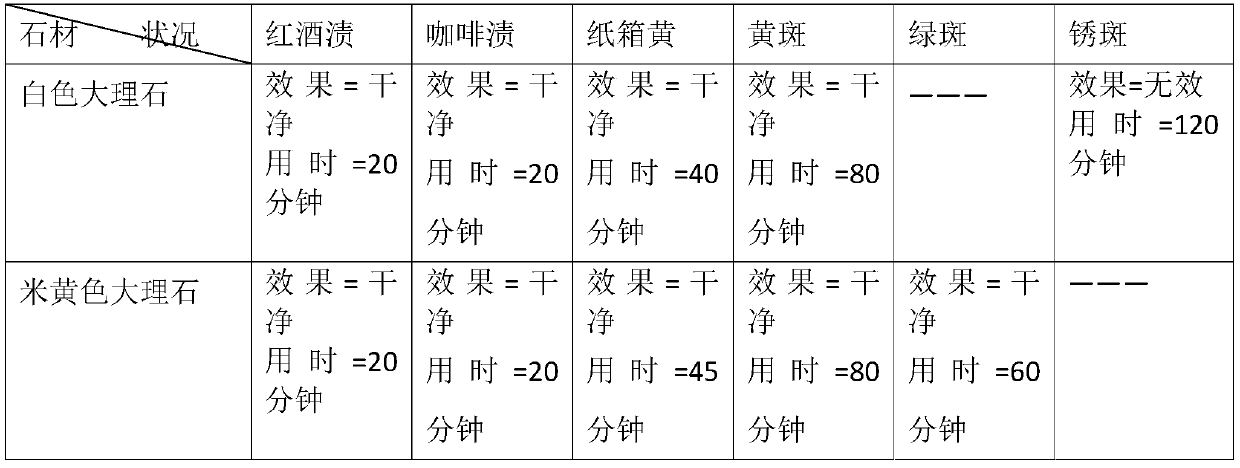

[0039] Apply the above-mentioned mixed paste cleaning agent on the stain or pollution on the stone surface to form an application layer, the thickness of the application layer is about 3-6mm, and keep it for 120 minutes. During the period, observe the effect at intervals of about 20 minutes, and clean the application layer with a spatula or brush at 120 minutes. The effect description is shown in Table 2.

[0040] Table I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com