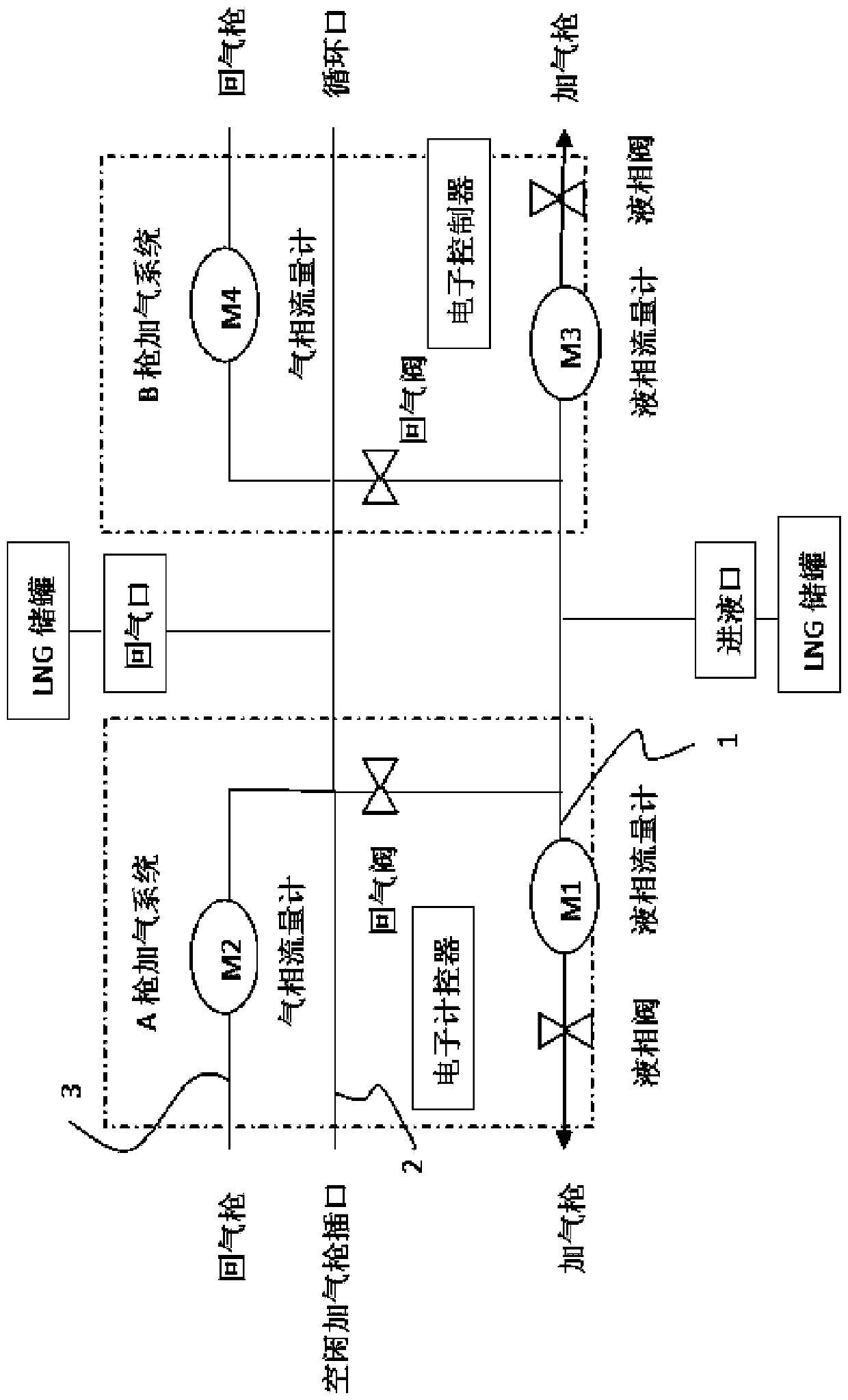

Gas filling control system and method of LNG double-gun gas filling machine

A control method and technology for a control system are applied in the control field of LNG double-gun gas dispensers, and can solve the problems of split flow, reduction of gas charging system flow rate, and increase of gas dispenser cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

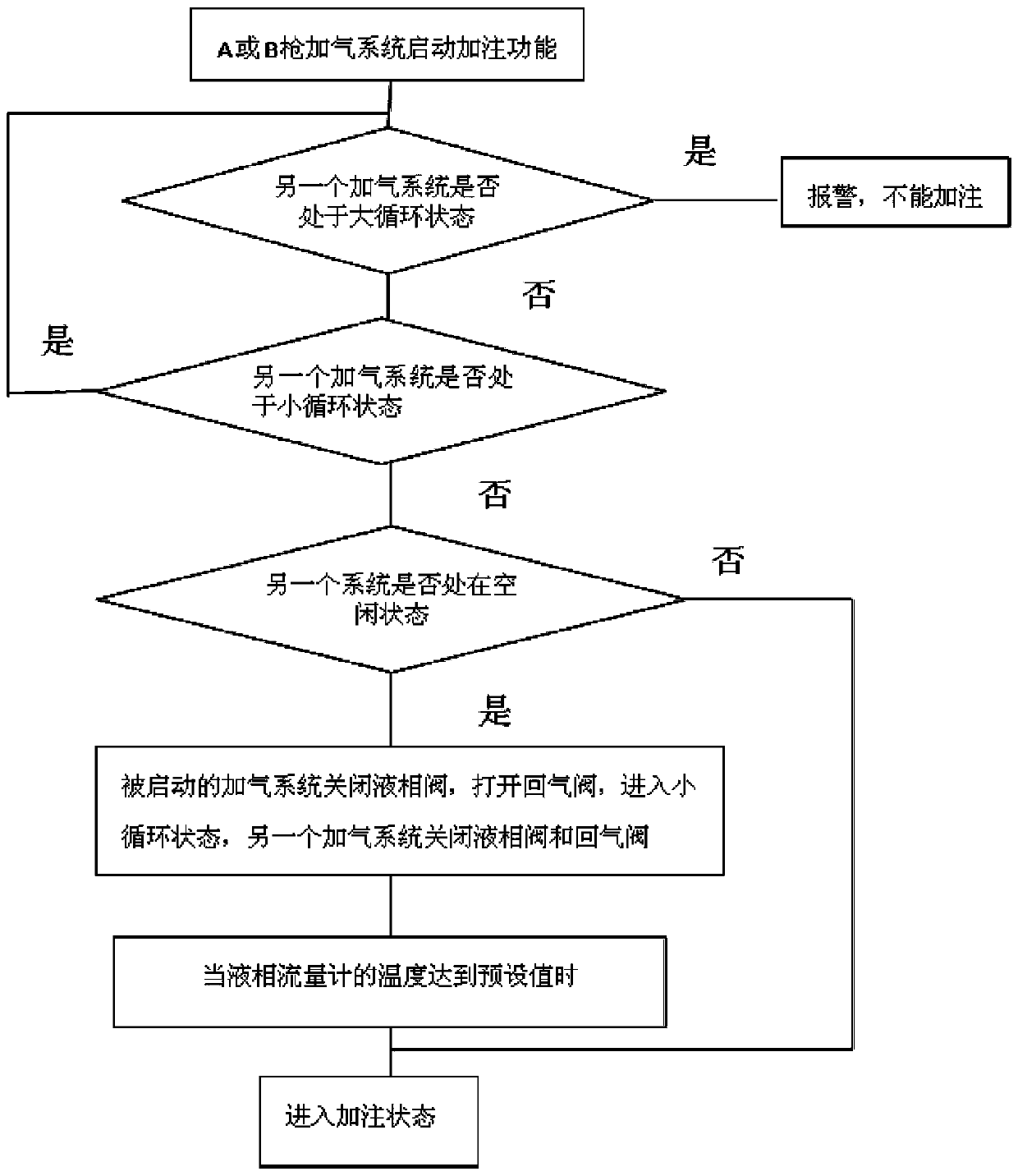

[0050] Embodiment 1, the working process of starting the filling function of the A gun gas filling system is as follows:

[0051] 1) Insert the air gun of the gas filling system of gun A into the gas filling port of the car's gas storage container, and insert the return air gun into the gas return port of the car's gas storage container, and press the filling button of the gas filling system of gun A , to start the filling function of the gas filling system.

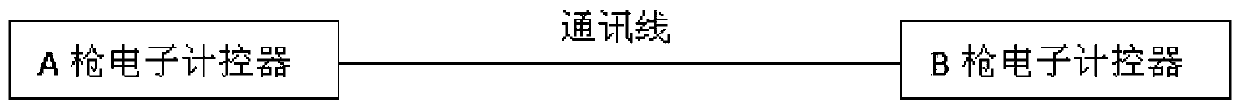

[0052] 2) The electronic controller of the gas filling system of the gun A obtains the current operating status of the gas filling system of the gun B through the detection of the communication line;

[0053] 2-1) First, the gas filling system of gun A detects whether the gas filling system of gun B is in a large cycle state. If it is, the electronic controller of the gas filling system of gun A sends out an alarm signal. Gas conditions, the gas filling system of gun A cannot be filled; if not, check whether the gas fil...

Embodiment 2

[0057] Embodiment 2, the operation process of the large cycle state of the gas filling system of the A gun includes:

[0058] 1) Insert the air gun of the gas filling system of gun A into the socket of the free gas filling gun, and press the precooling key of the gas filling system of gun A.

[0059] 2) The electronic controller of the gas filling system of gun A detects whether the gas filling system of gun B is in an idle state through the communication line.

[0060] 2-1) When it is detected that the gas filling system of gun B is not in the idle state, the electronic controller will send out an alarm signal, indicating that another gas filling system is working at this time, and the gas filling system of gun A cannot be pre-cooled;

[0061] 2-2) When it is detected that the gas filling system of gun B is in an idle state, close the liquid phase valve and the return valve in the gas filling system of gun B, and the gas filling system of gun A opens the liquid phase valve an...

Embodiment 3

[0063] Embodiment 3, when the two gas filling systems are filled at the same time, the control process of the gas filling system of the B gun ending the filling in advance is as follows:

[0064] 1) When the gas filling systems of gun A and gun B are both in the filling state, the gas filling system of gun B ends filling ahead of time;

[0065] 2) Close the liquid phase valve and return air valve of the gas filling system of gun B;

[0066] 3) When the gas filling system of A gun is also finished filling, the two gas filling systems are idle, and then open their respective return valves, close their respective liquid phase valves, and enter the idle state.

[0067] On the basis of the existing pipeline structure of the double gun gas filling machine, the present invention only needs to add a communication line between the electronic controllers of the two gas filling systems to realize the mutual operation status of the two gas filling systems. The lock control enables the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com