Drying device for SHA production

A drying device and drying cylinder technology, applied in the direction of drying gas arrangement, drying solid materials, drying chamber/container, etc., can solve the problems such as unsatisfactory effect, achieve the effect of increasing stirring, good drying effect and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

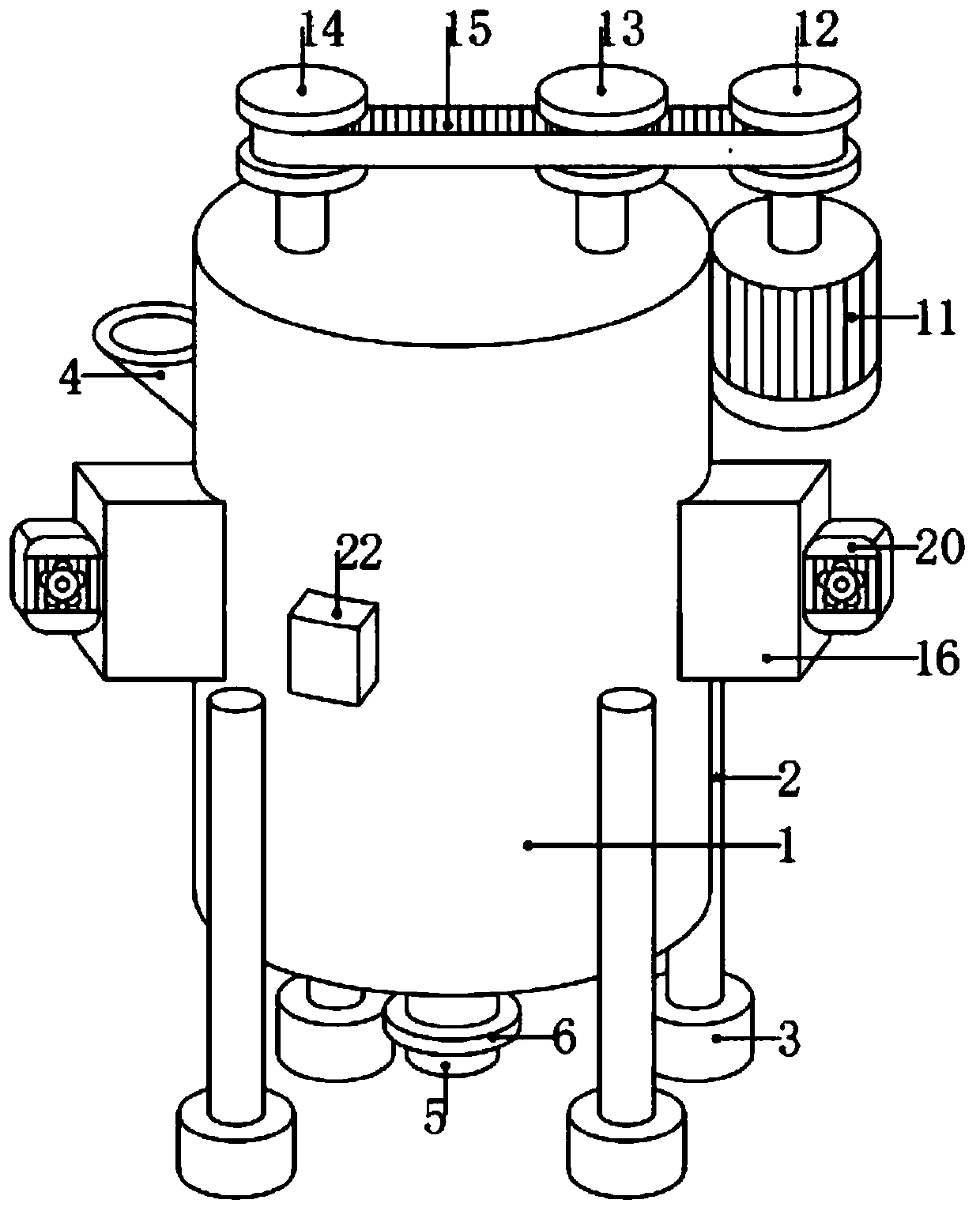

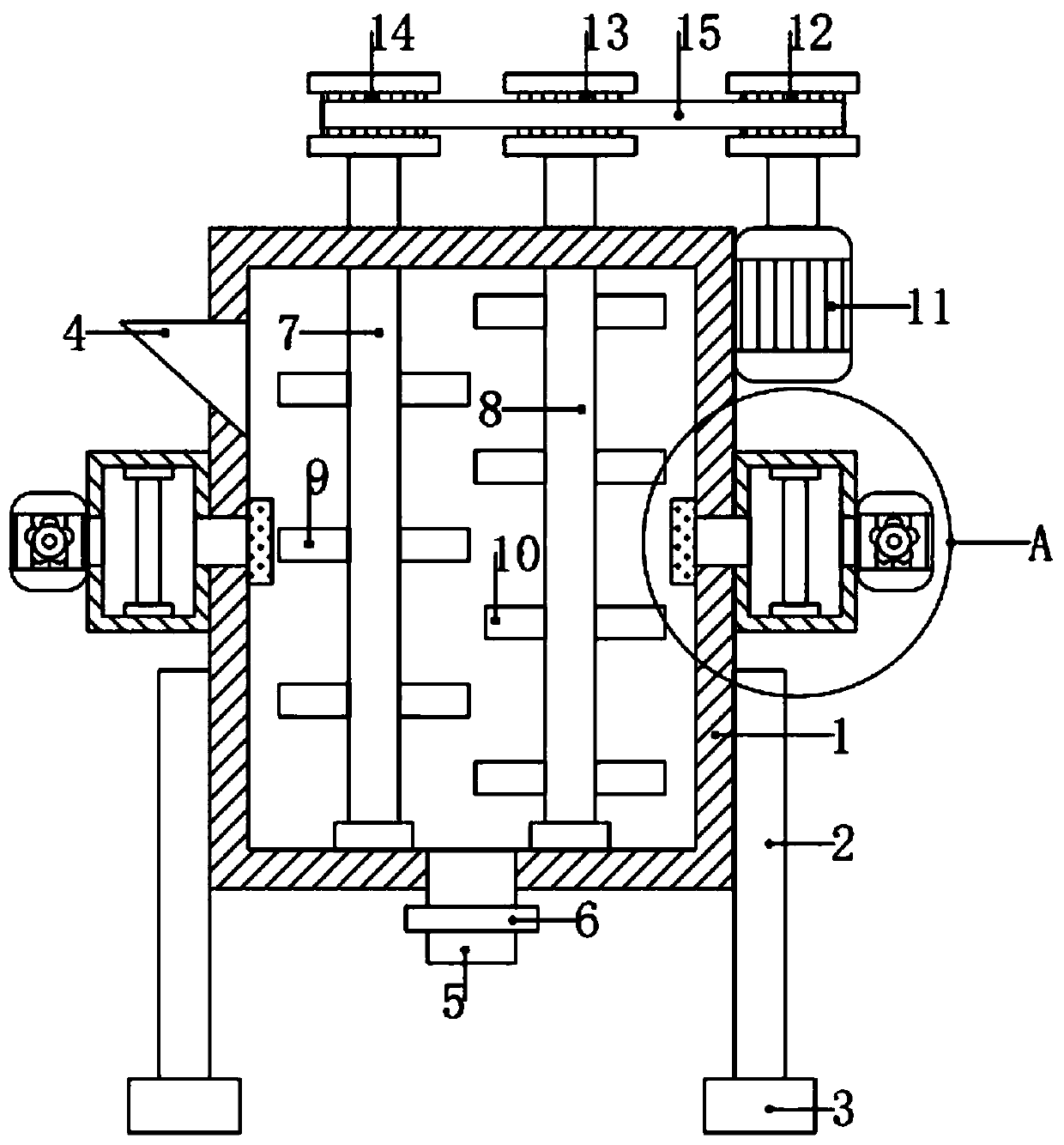

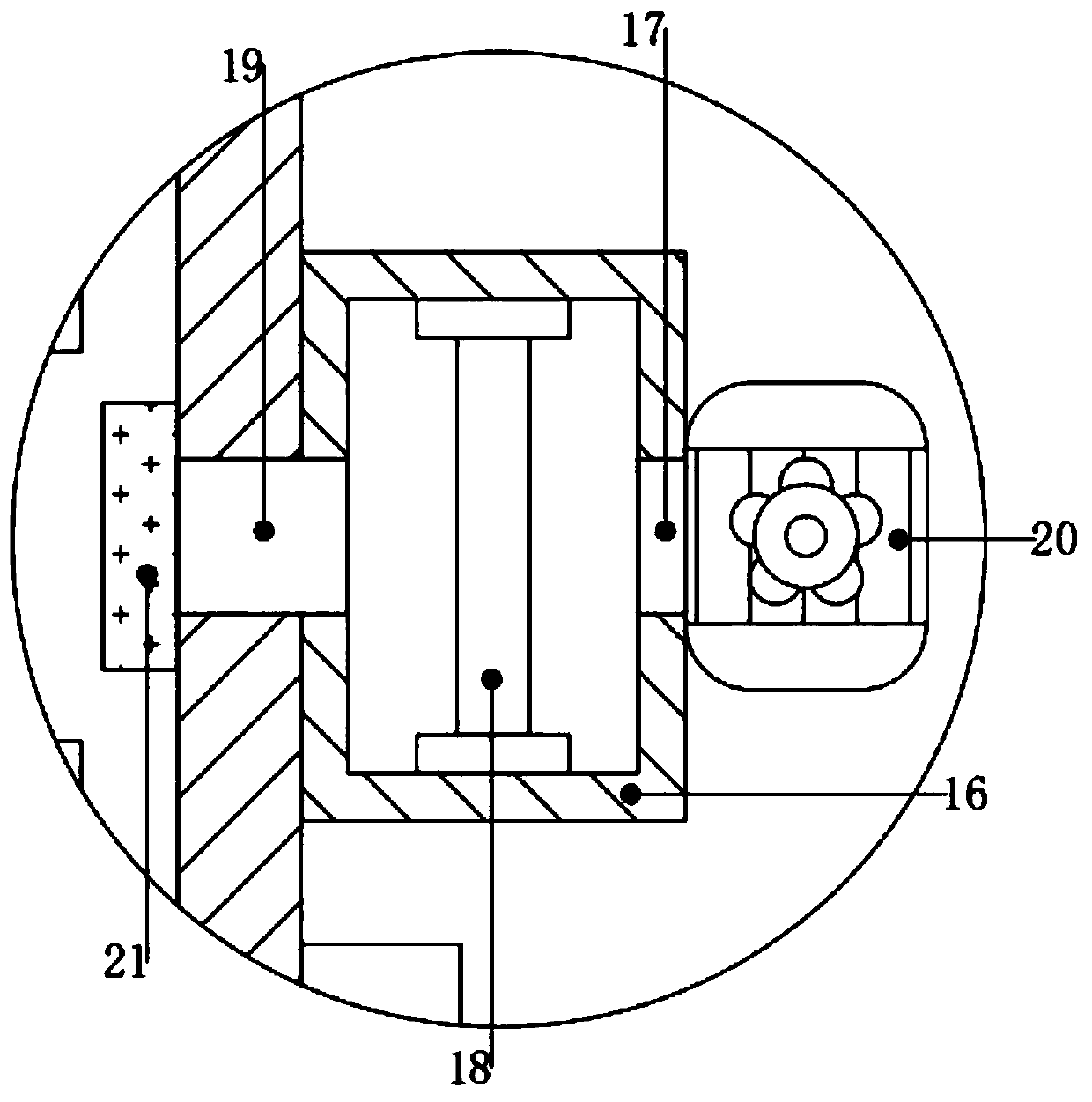

[0033] combine figure 1 with figure 2 Shown is a drying device for buffer fertilizer production, comprising a drying cylinder 1, support feet 2, feed inlet 4, discharge outlet 5 and discharge valve 6, the surface of the drying cylinder 1 is galvanized, and the support feet 2 are provided with Four, and the four supporting feet 2 are respectively fixed on the outer end of the drying cylinder 1, and the lower ends of the four supporting feet 2 are fixed with a shock-absorbing seat 3, and the surface of the shock-absorbing seat 3 is wrapped with a shock-absorbing pad, and the feed port 4 It is fixed on the left end of the drying cylinder 1, the inner wall of the feed port 4 is polished and smooth, the discharge port 5 is fixed on the lower end of the drying cylinder 1, the discharge valve 6 is installed on the discharge port 5, and the drying cylinder 1 is equipped with a speed Stirring device with high drying efficiency, and part of the stirring device extends to the upper sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com