Method for treating high-fluorine-content wastewater by utilizing fly ash

A fly ash and waste water technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of lack of large adsorption capacity, low-cost adsorbent, poor treatment effect and high treatment cost , achieve the effect of shortening the heating reaction time and improving the efficiency of fluorine removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

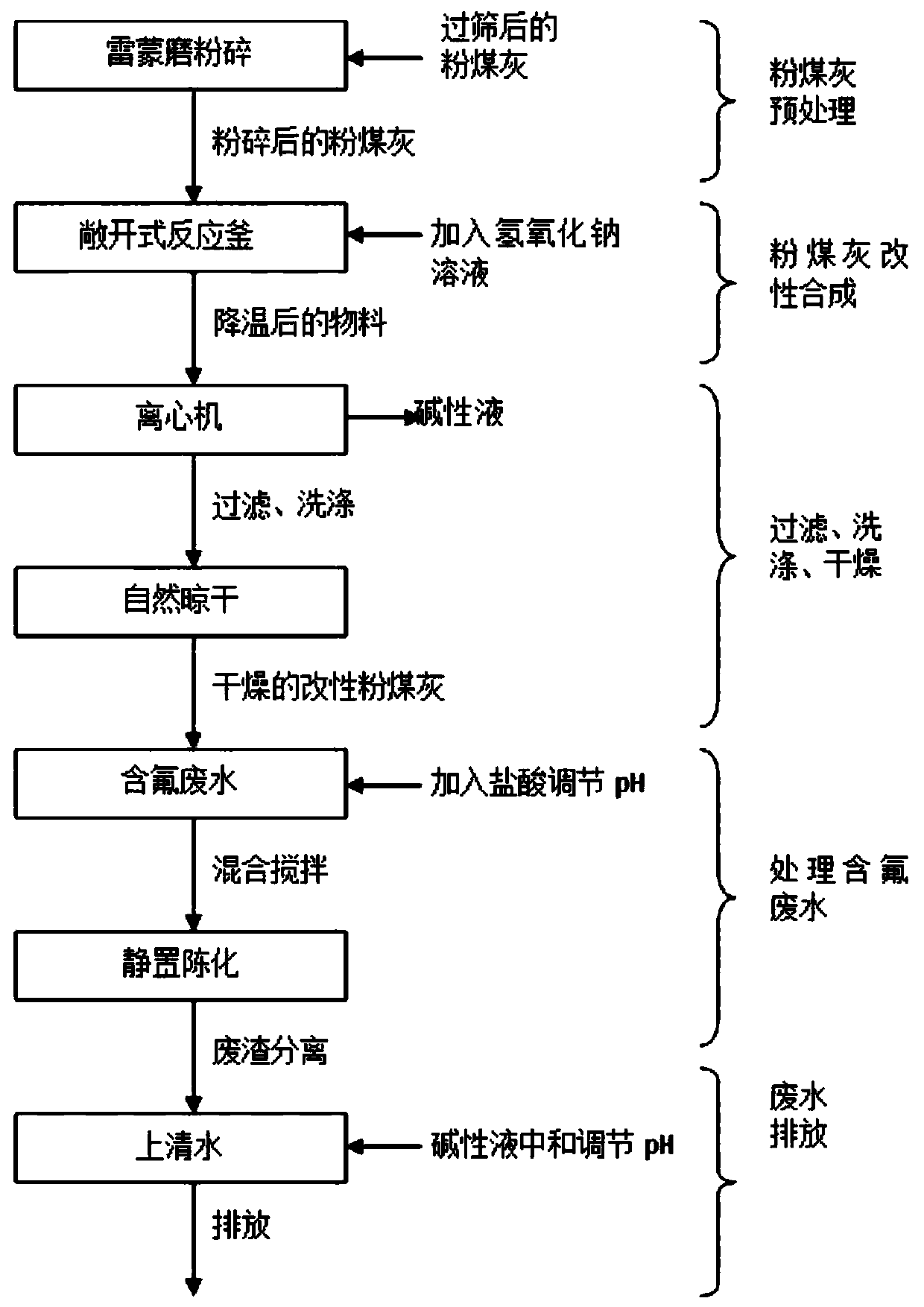

[0036] A method of utilizing fly ash to treat high fluorine-containing wastewater comprises the following steps:

[0037] a. Pretreatment of fly ash: get the fly ash to pick out the impurities mixed therein, use Raymond mill to grind the fly ash evenly, then pass through a 300 mesh sieve for subsequent use; get the pretreated fly ash (containing 47.8g SiO 2 and 40.2g Al 2 o 3 ) 100g and 500g concentration are 3mol / L sodium hydroxide solution (alkaline density is 1.12g / cm 3 ) in an open reactor at a reaction temperature of 95-100°C, a stirring speed of 100 rpm and a reaction time of 6 hours for a modification reaction, and then the reaction product is cooled and separated from solid and liquid by a centrifuge to obtain a modification Reactive solid phase and alkaline liquid, take the modified solid phase, filter and dry naturally to obtain modified fly ash; in step a, the modification reaction adopts electric heating or oil bath heating to heat the reactor ; The modificatio...

Embodiment 2

[0042] In step a, the liquid-solid ratio of sodium hydroxide solution and the fly ash after pretreatment is 4:1, and other technical schemes are the same as embodiment 1, and the fluorine removal rate is 81.9%.

Embodiment 3

[0044] The sodium hydroxide solution adopts 2mol / L in the step a, and other technical schemes are the same as embodiment 1, and the fluorine removal rate is 79.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com