Synthesis method of adsorbent for removing fluorine in high salt

A synthesis method and adsorbent technology, which is applied in the field of fluorine removal adsorbent synthesis in high salt, can solve the problems of low fluorine removal efficiency, secondary pollution, high operation and maintenance costs, etc., and achieve high fluoride removal capacity and affinity, Efficient defluorination and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

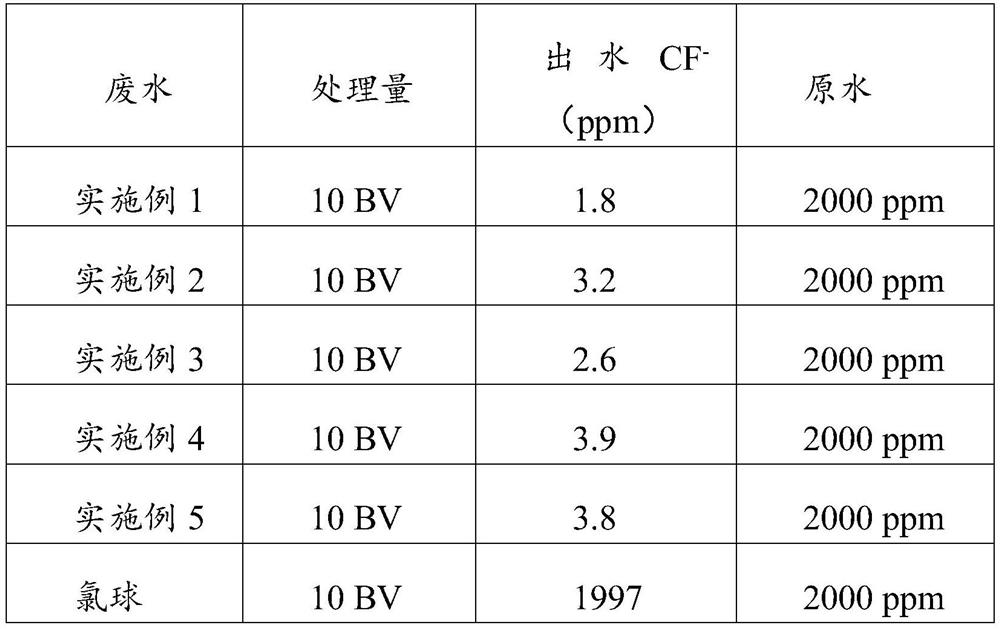

Embodiment 1

[0035] 1. Put 2g of chlorine ball resin (made by Jiangsu Haipu Functional Materials Co., Ltd.) into a three-necked flask, add 50mL of absolute ethanol to swell, and stir at room temperature for 8h.

[0036] 2. Add 10 mL of 20% NaOH aqueous solution and 2 g of 2-aminoquinoline-6-carboxamide, stir at 40° C. for 3 hours, and then filter the excess reaction solution with suction.

[0037] 3. Add 2 g of 2-aminoquinoline-3-carboxylic acid and 50 mL of DMSO to the above resin, and react under reflux at 80° C. for 4 h. Suction filtration, washing with ethanol and deionized water 3 times.

[0038] 4. Mix 1g of heavy metal salt solution: Cu(NO 3 ) 2 Dissolve in 50 mL of a mixed solution of ethanol and water with a volume ratio of 1:1.

[0039] 5. Add the above-mentioned resin to the above-mentioned nitrate solution, distill under reduced pressure at 80°C for 4 hours, filter the excess solution with suction, wash with distilled water until neutral, and dry in an oven at 60°C.

Embodiment 2

[0041] 1. Add 3g of chlorine ball resin (made by Jiangsu Haipu Functional Materials Co., Ltd.) into a three-necked flask, add 60mL of DMF to swell, and stir at room temperature for 8h.

[0042] 2. Add 10 mL of 30% NaOH aqueous solution and 2 g of 2-aminoquinoline-4-carboxamide, stir at 50° C. for 3 hours, and then filter the excess reaction solution with suction.

[0043] 3. Add 2 g of 2-aminoquinoline-3-carboxylic acid and 60 mL of DMF to the above resin, and react under reflux at 80° C. for 4 h. Suction filtration, washing with ethanol and deionized water 3 times.

[0044] 4. Mix 2g of heavy metal salt solution: Ce(NO 3 ) 3 Dissolve in 50mL of a mixed solution of ethanol and water with a volume ratio of 1:2.

[0045] 5. Add the above-mentioned resin to the above-mentioned nitrate solution, distill under reduced pressure at 70°C for 4 hours, filter the excess solution with suction, wash with distilled water until neutral, and dry in an oven at 70°C.

Embodiment 3

[0047] 1. Put 8g of chlorine ball resin (made by Jiangsu Haipu Functional Materials Co., Ltd.) into a three-necked flask, add 100mL of toluene to swell, and stir at room temperature for 10h.

[0048] 2. Add 10 mL of 50% NaOH aqueous solution and 4 g of 2-aminoquinoline-6-carboxamide, stir at 60° C. for 6 hours, and then filter the excess reaction solution with suction.

[0049] 3. Add 5 g of 4-aminoquinoline-3-carboxylic acid and 100 mL of acetone to the above resin, and react under reflux at 100° C. for 7 h. Suction filtration, washing with ethanol and deionized water 3 times.

[0050] 4. Mix 7g of heavy metal salt solution: Zr(NO3 ) 4 Dissolve in 100mL of a mixed solution of ethanol and water with a volume ratio of 1:4.

[0051] 5. Add the above-mentioned resin to the above-mentioned nitrate solution, distill under reduced pressure at 100°C for 6 hours, filter the excess solution with suction, wash with deionized water until neutral, and dry in an oven at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com