Compound taking quinolinone derivative as core and application of compound in organic electroluminescent device

A compound and derivative technology, applied in the application field of organic electroluminescent devices, can solve problems such as performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

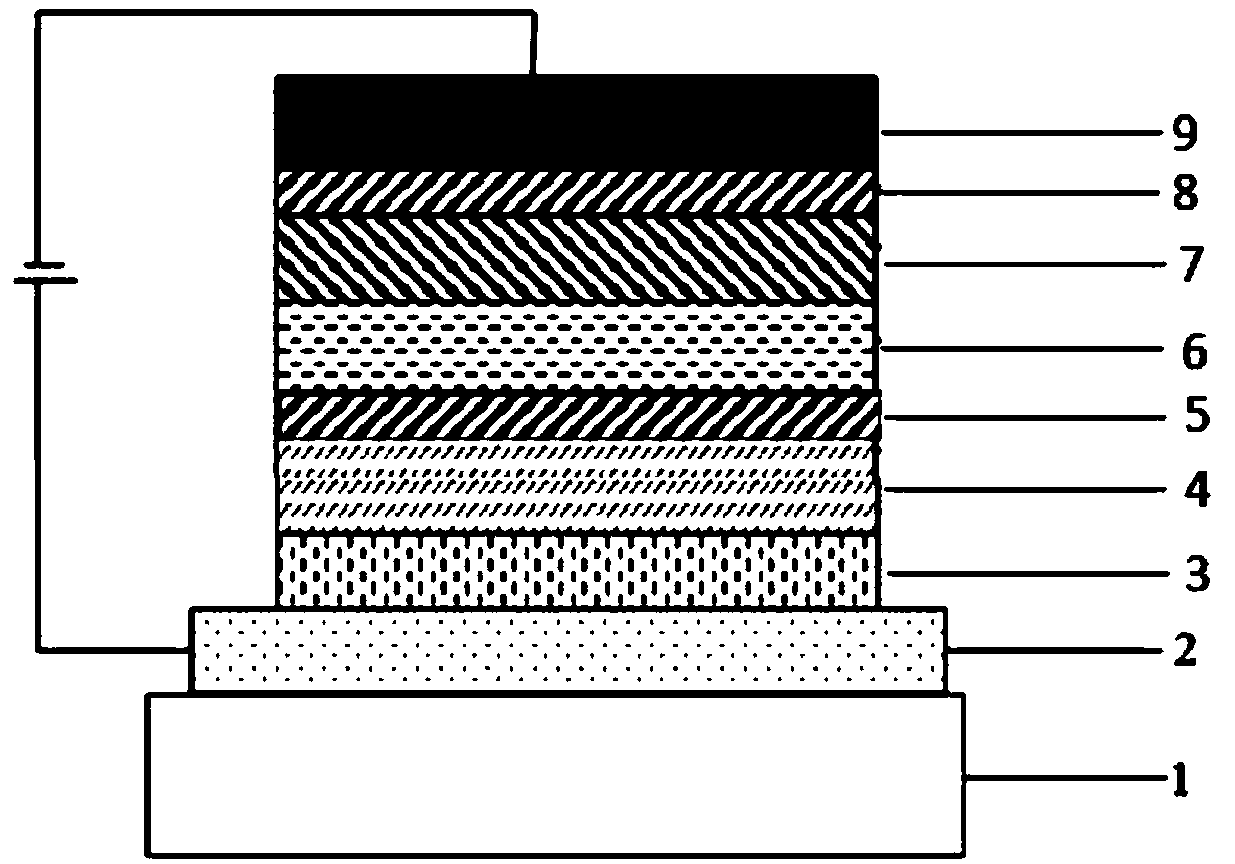

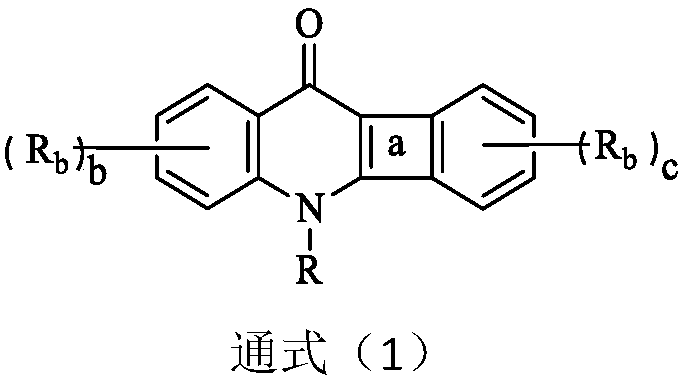

Method used

Image

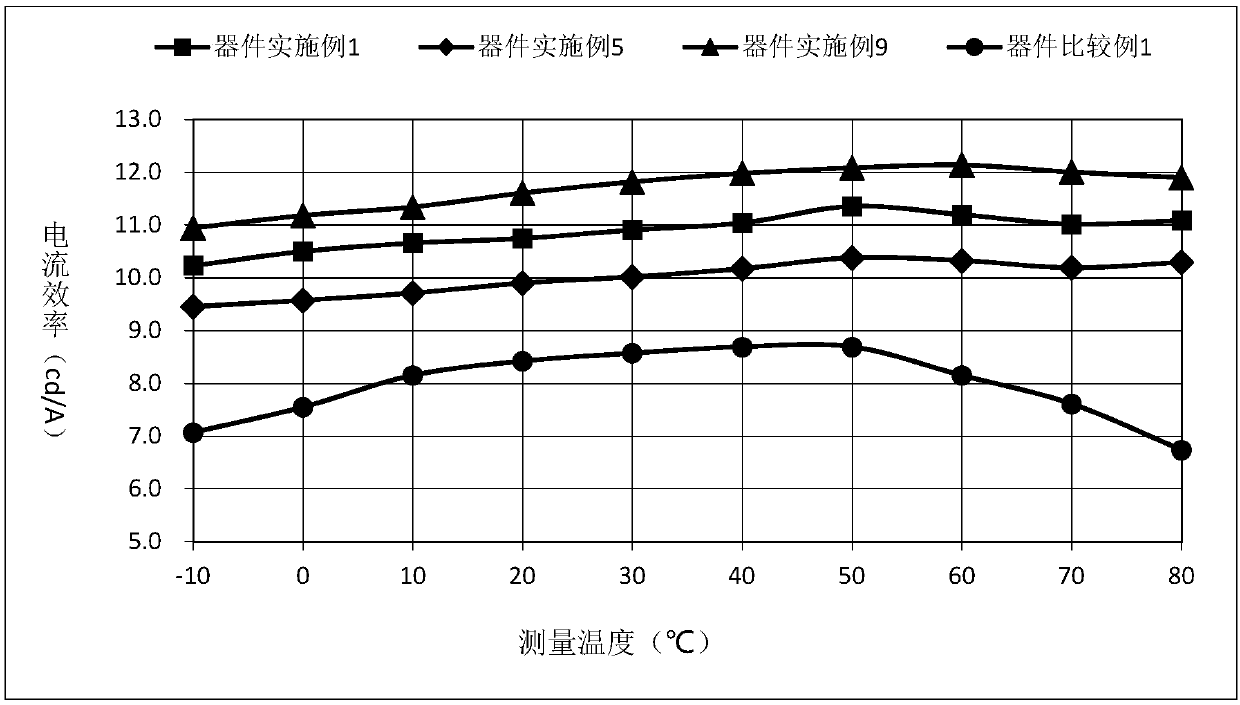

Examples

preparation example Construction

[0067] Preparation of Intermediate B:

[0068] Preparation of Intermediate I-1:

[0069]

[0070] (1) 500mL three-necked flask, under nitrogen protection, add 0.05mol raw material C-1, 0.06mol raw material D-1, dissolve with mixed solvent (180ml toluene, 90ml ethanol), then add 0.15mol Na 2 CO 3 Aqueous solution (2M), stirred with nitrogen for 1 hour, then added 0.0005mol Pd (PPh 3 ) 4 , 100 ℃ heating reflux for 15 hours, sampling point plate, the reaction is complete. Naturally cooled, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain intermediate L-1 with HPLC purity of 93.4% and yield of 64.2%.

[0071] Elemental analysis structure (molecular formula C 23 H 17 BrS 2 ): Theoretical C, 63.16; H, 3.92; Br, 18.27; S, 14.66; Tested: C, 63.15; H, 3.92; Br, 18.27; S, 14.67. ESI-MS (m / z) (M+): theoretical value 436.00, found value 436.12.

[0072] (2) Under nitrogen protection, weigh 0.01 mol of intermediate L-1 and 0.012 mol...

Embodiment 1

[0104] Example 1: Synthesis of Compound 2:

[0105]

[0106] In a 250mL three-necked flask, nitrogen was introduced, 0.01mol of raw material A-1 and 0.015mol of Intermediate I-1 were added, dissolved in a mixed solvent of toluene and ethanol (90mL of toluene and 45mL of ethanol), and then 0.03mol of Na was added. 2 CO 3 Aqueous solution (2M), stirred with nitrogen for 1h, then added 0.0001mol Pd (PPh 3 ) 4 , 100 ℃ heating under reflux for 15h, sampling point plate, the reaction is complete. Natural cooling, filtration, rotary evaporation of the filtrate, and passage of the residue through a silica gel column to obtain the target product with a purity of 98.1% and a yield of 84.9%. Elemental analysis structure (molecular formula C 52 H 36 N 2 OS): Theoretical C, 84.75; H, 4.92; N, 3.80; O, 2.17; S, 4.35; Tested: C, 84.75; H, 4.91; N, 3.82; O, 2.17; ESI-MS (m / z) (M+): Theoretical value is 736.25, and the found value is 736.19.

Embodiment 2

[0107] Example 2: Synthesis of Compound 12:

[0108]

[0109] The preparation method of compound 12 is the same as that of Example 1, except that the starting material A-2 is used to replace the starting material A-1, and the intermediate II-1 is used to replace the intermediate I-1. Elemental analysis structure (molecular formula C 51 H 36 N 4 O): theoretical C, 84.97; H, 5.03; N, 7.77; O, 2.22; found: C, 84.96; H, 5.03; N, 7.77; O, 2.23. HPLC-MS: The molecular weight of the material is 720.29, and the measured molecular weight is 720.35.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com