Method for improving adhesive force between polyester cord and coating rubber

A technology of polyester cord and rubber sticking, applied in fiber types, textiles and paper making, ultrasonic/sonic fiber treatment, etc., to avoid environmental pollution, improve adhesion, and stabilize quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

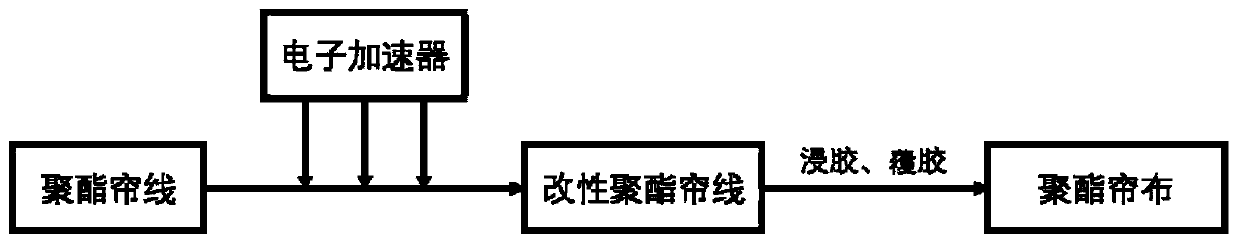

Method used

Image

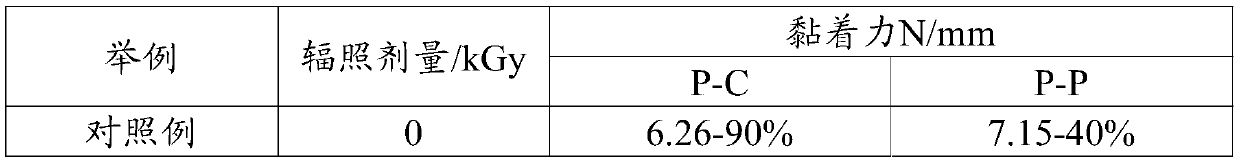

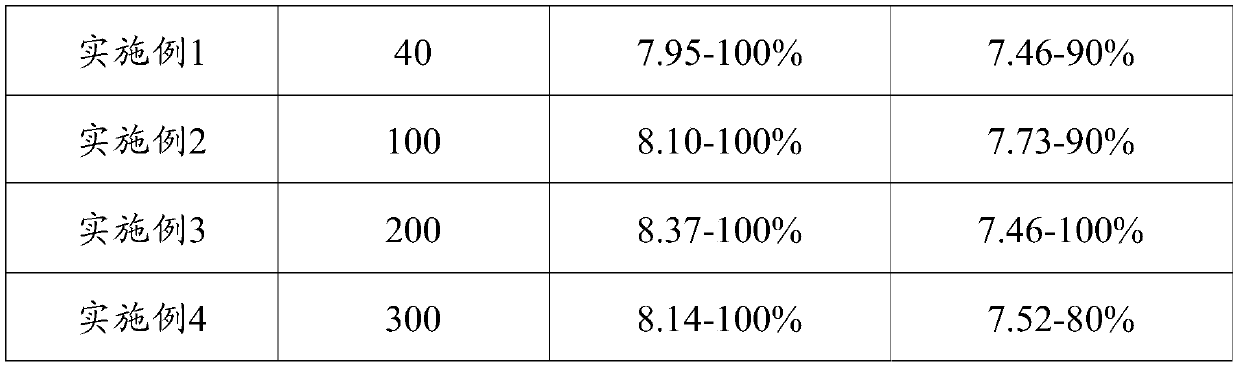

Examples

Embodiment 1

[0019] The polyester cord is placed on the transmission device, and the transmission device carries the polyester cord into the irradiation room at a certain speed, and passes through the scanning window of the electron accelerator in the irradiation room to complete the irradiation of the polyester cord. When the polyester cord passes through the scanning window of the electron accelerator, the electron beam energy of the electron accelerator is 1MeV, the beam current intensity of the electron beam is 8mA, the temperature of the irradiation room is 30°C, and the transmission speed of the transmission device is 5m / min. The irradiation dose is 40kGy, normal pressure, air atmosphere, and the irradiation times are 1 time. After irradiation, the second dipping method is used for dipping. The dipping method is to scrape the sample by hand, and the rubber is covered with natural rubber to obtain polyester cord. The adhesion test of the polyester cord was carried out according to the...

Embodiment 2

[0021] The polyester cord is placed on the transmission device, and the transmission device carries the polyester cord into the irradiation room at a certain speed, and passes through the scanning window of the electron accelerator in the irradiation room to complete the irradiation of the polyester cord. When the polyester cord passes through the scanning window of the electron accelerator, the electron beam energy of the electron accelerator is 1MeV, the beam current intensity of the electron beam is 6.5mA, the temperature of the irradiation chamber is 60°C, and the transmission speed of the transmission device is 5m / min. The irradiation dose is 100kGy, normal pressure, air atmosphere, and the irradiation times are 3 times. After irradiation, the second dipping method is used for dipping. The dipping method is to scrape the sample by hand, and the rubber is covered with natural rubber to obtain polyester cord. The adhesion test of the polyester cord was carried out according...

Embodiment 3

[0023] The polyester cord is placed on the transmission device, and the transmission device carries the polyester cord into the irradiation room at a certain speed, and passes through the scanning window of the electron accelerator in the irradiation room to complete the irradiation of the polyester cord. When the polyester cord passes through the scanning window of the electron accelerator, the electron beam energy of the electron accelerator is 1MeV, the beam current intensity of the electron beam is 12mA, the temperature of the irradiation room is 60°C, and the transmission speed of the transmission device is 5m / min. The irradiation dose is 200kGy, normal pressure, air atmosphere, and the irradiation times are 4 times. After irradiation, the second dipping method is used for dipping. The dipping method is to scrape the sample by hand, and the rubber is covered with natural rubber to obtain polyester cord. The adhesion test of the polyester cord was carried out according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com