Oil slip ring for wind generating set

A wind turbine, oil-smooth technology, applied in the direction of wind turbines, wind power generation, engines, etc., can solve the problems of short service life of seals, low reliability requirements, low maintenance costs, etc., to reduce the increase speed and improve the overall Reliability and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific examples.

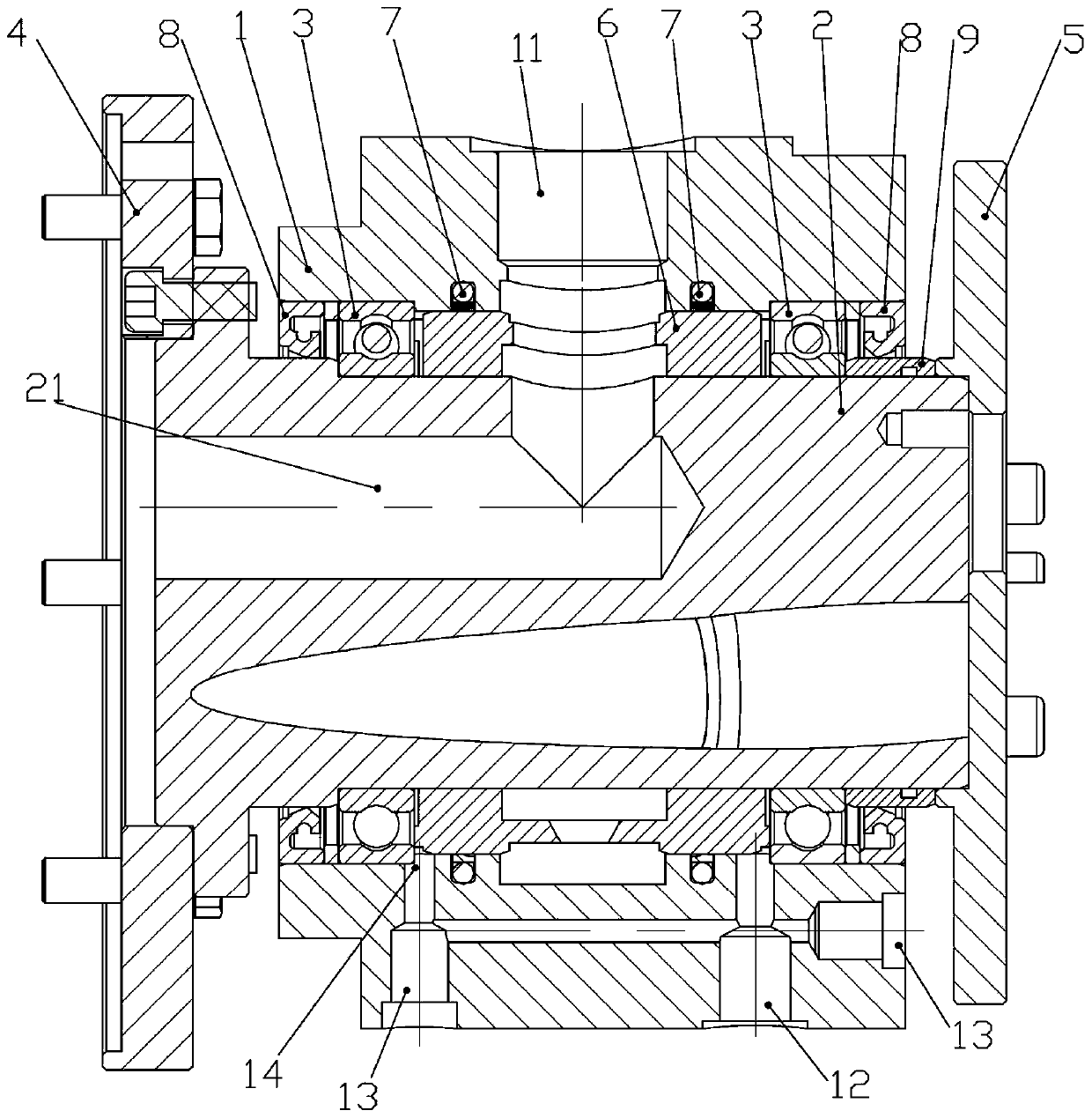

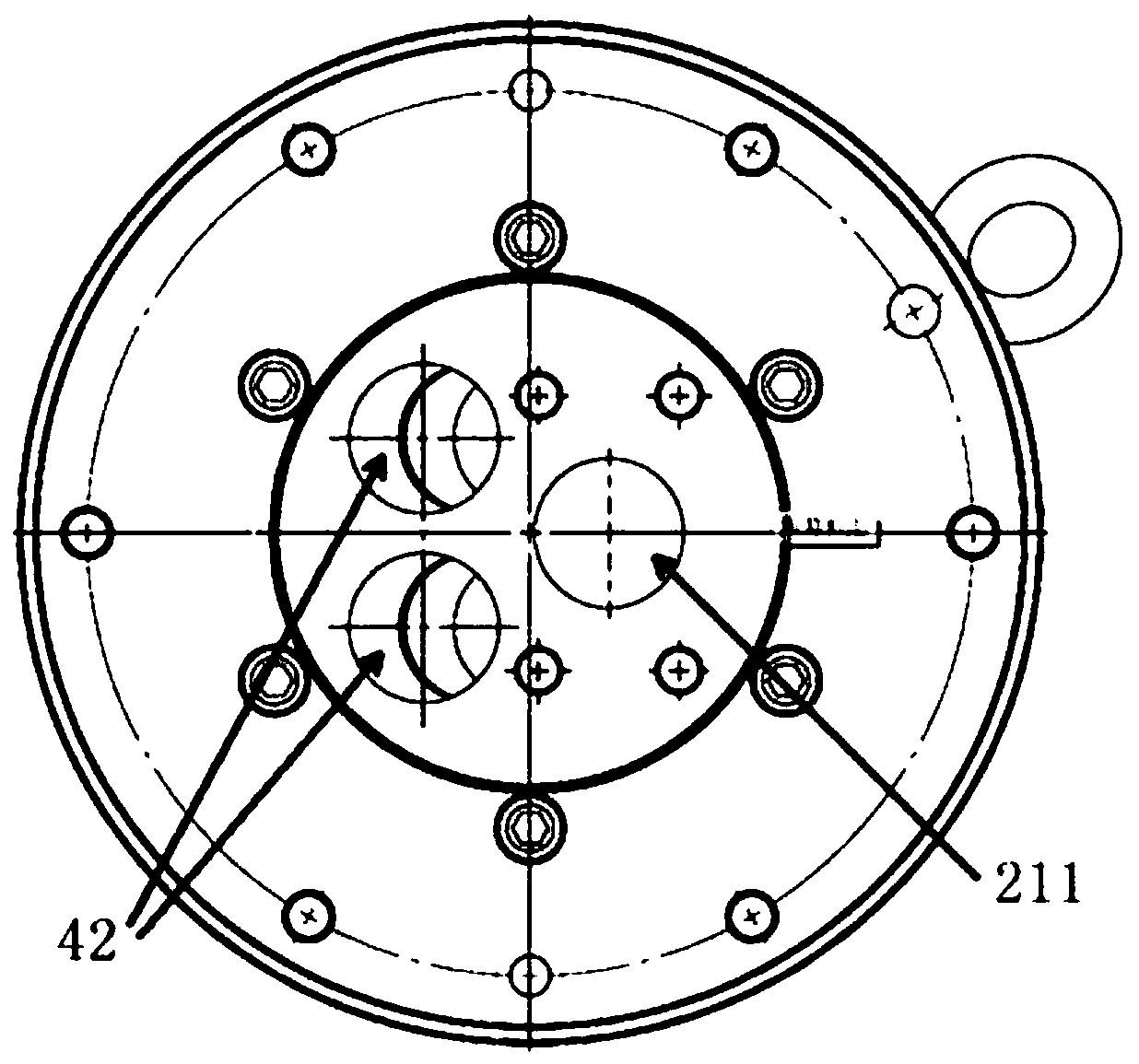

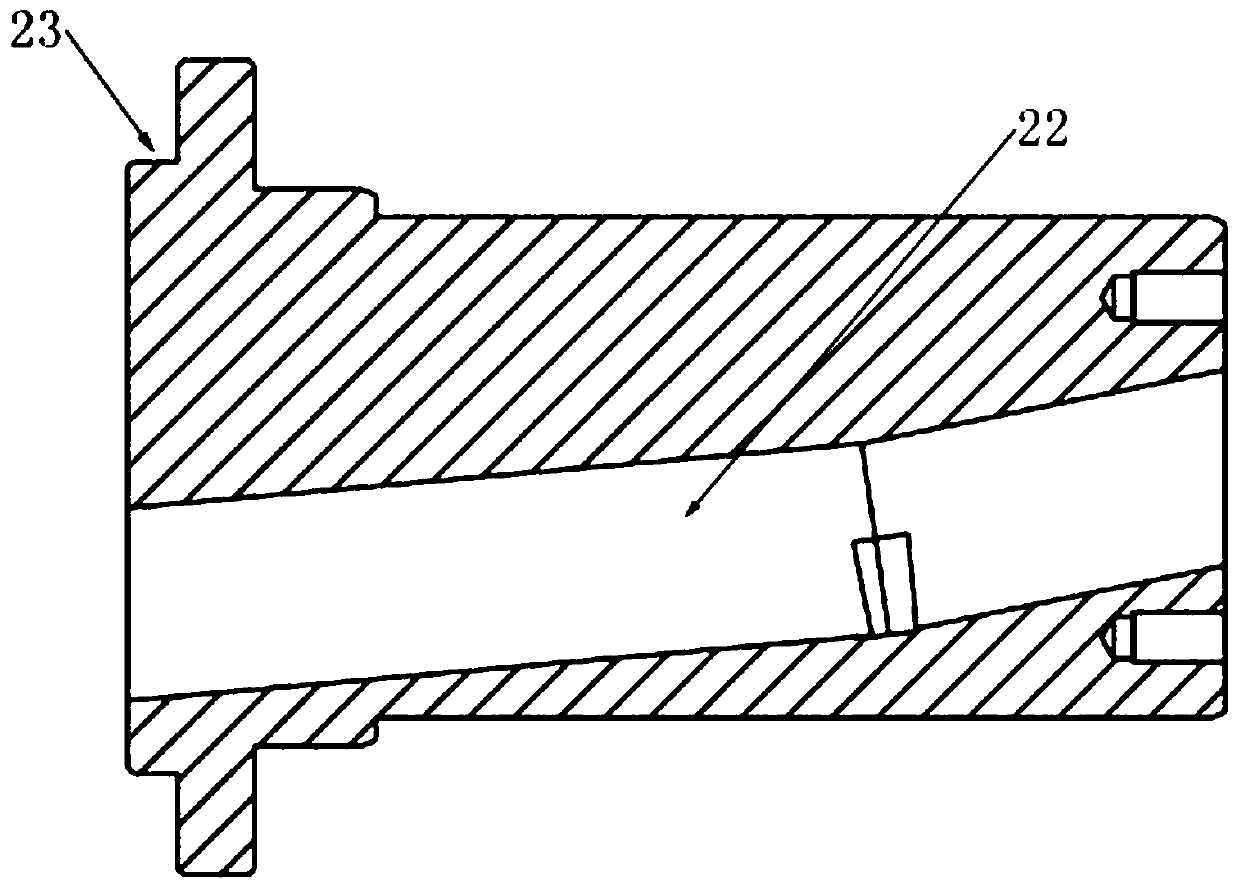

[0016] Such as Figure 1 to Figure 6 As shown, the wind turbine oil slip ring described in this embodiment includes a housing 1, a rotating mandrel 2, a bearing 3, a front flange 4, a rear flange 5, a floating sleeve 6, an elastic sealing ring 7, a rotating shaft seal 8 and a spacer 9, the housing 1 is fixed on the cabin wall of the wind power generator through an external anti-rotation rod, that is, the housing 1 is stationary relative to the cabin, and an oil inlet 11 and an oil drain 12 are processed on its circumferential surface , the rotating mandrel 2 is installed in the housing 1 through two bearings 3 (in order to facilitate the disassembly and assembly of the bearing 3, the two joints of the rotating mandrel 2 and the bearing 3 can also be designed to have different shaft diameters, and the bearings 3 Two kinds of specifications are selected for installation), and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com