Low-torque ripple sensorless control method for synchronous reluctance motor

A synchronous reluctance motor and torque ripple technology, applied in torque ripple control, motor generator control, electronic commutation motor control, etc., can solve problems such as noise pollution, high-frequency torque ripple, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

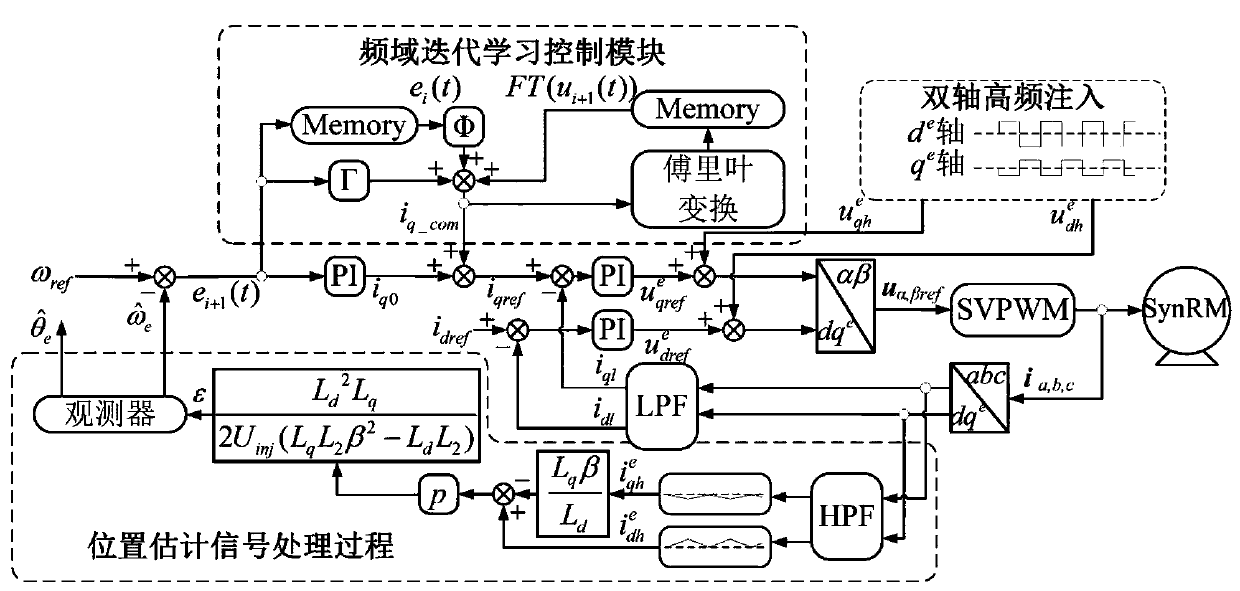

[0067] Specific implementation mode 1. Combination figure 1 As shown, the present invention provides a sensorless control method for low torque ripple of a synchronous reluctance motor, comprising:

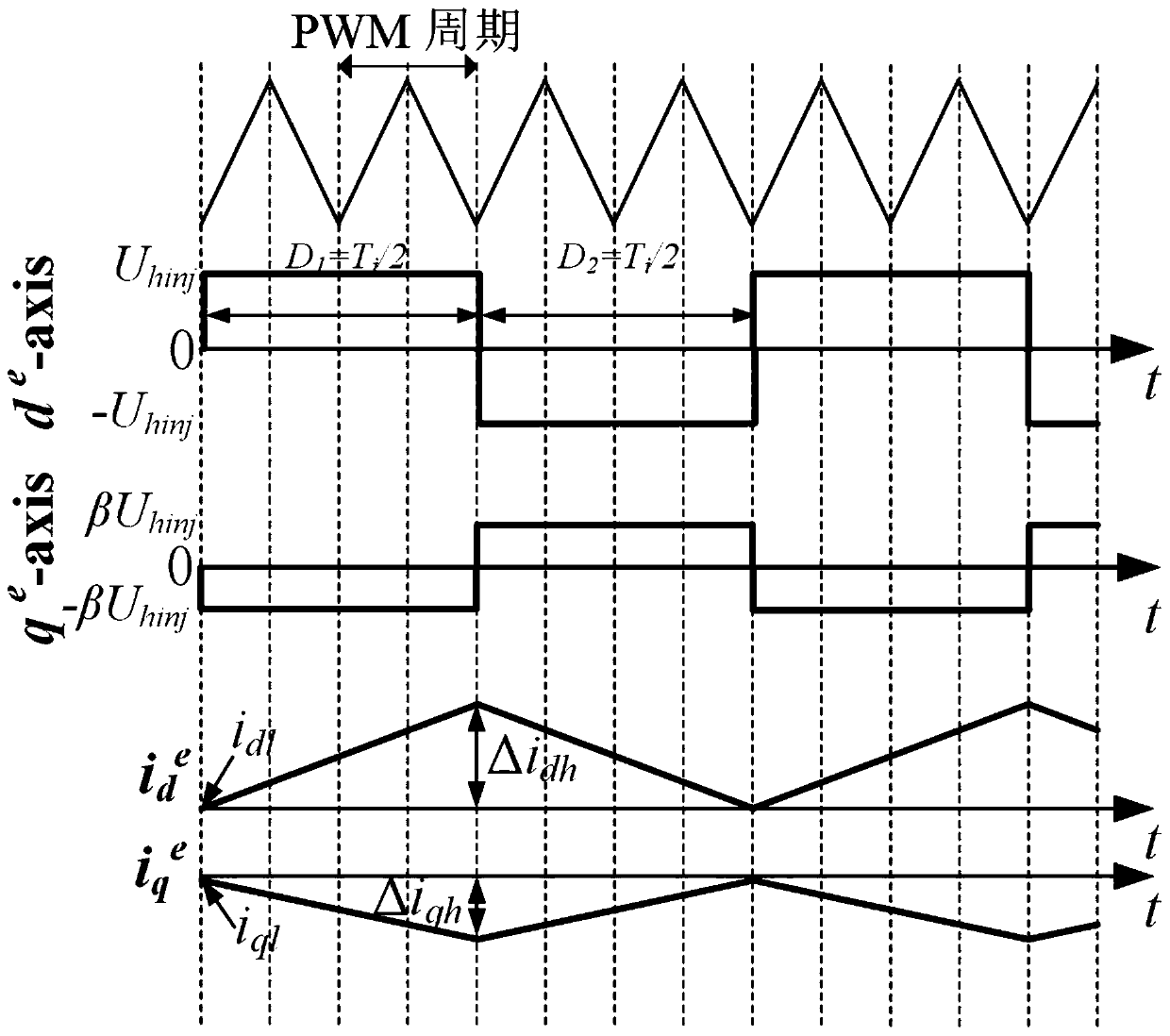

[0068] During the operation of the synchronous reluctance motor, a predetermined high-frequency pulse voltage with the same phase and a fixed amplitude is injected into the dq axis of the synchronous reluctance motor at the same time; the dq axis refers to the rotating coordinate system of the motor, and dq The shaft system includes a d-axis and a q-axis, the d-axis points to the direction where the rotor reluctance is smaller, and the q-axis is perpendicular to the d-axis;

[0069] Extracting the three-phase pulse current in the abc three-phase shaft system of the synchronous reluctance motor, and transforming it into a current signal under the dq shaft system, performing differential calculation on the current signal under the dq shaft system and coupling with coupling parameter...

Embodiment 1

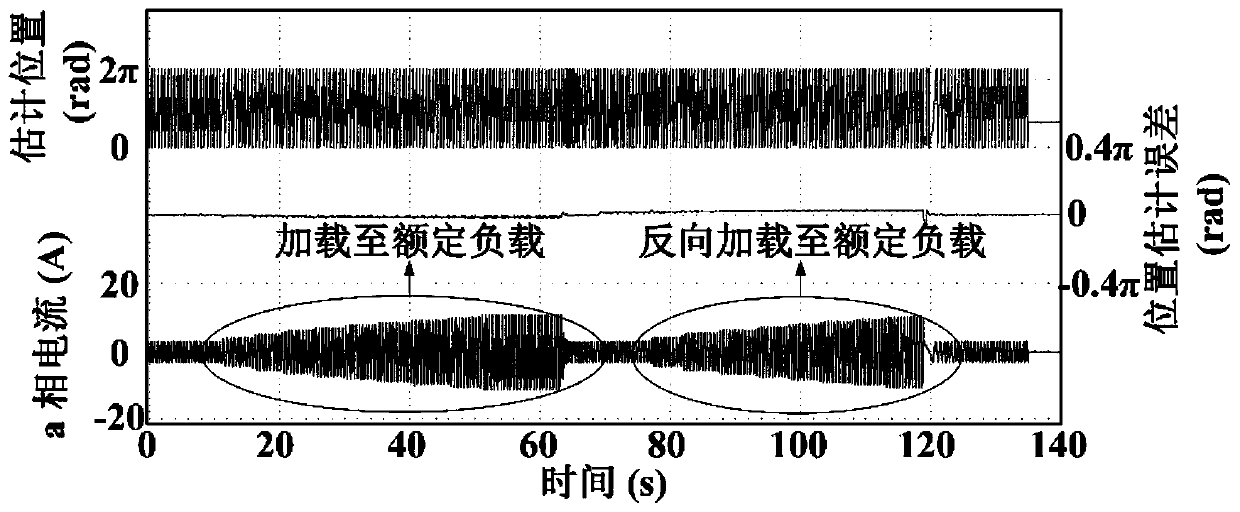

[0111] The verification is carried out on the synchronous reluctance motor towing experimental platform. A 3kW permanent magnet synchronous motor and a 5.5kW permanent magnet synchronous motor are connected through the JN338 torque speed tester, and the two inverters are connected by a common DC bus; the permanent magnet synchronous motor is used as the loading motor, and the synchronous reluctance motor is used as the test motor. The torque speed is monitored in real time by the torque tester. The system is equipped with an encoder to obtain the actual position and compare it with the observed signal; the vector control algorithm is implemented through STM32F103VBARM to control the synchronous reluctance motor; the inverter uses the PM25RLA120IPM power module, and the stator current passes through the PHA20VB15 Hall current sensor Detection; switching frequency 6kHz;

[0112] The main parameters of the synchronous reluctance motor used are: rated voltage 360V, rated current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com