Method for quickly preparing spiced beef seasoned with sauce

A rapid technology for stewed beef in sauce, applied in the fields of climate change adaptation, food science, etc., can solve the problems that it is difficult to ensure the flavor and taste of stewed beef in sauce and product quality, it is difficult to realize large-scale industrial production, and the production process costs are high. Improve the type and relative content, improve the efficiency of pickling, and reduce the effect of pickling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

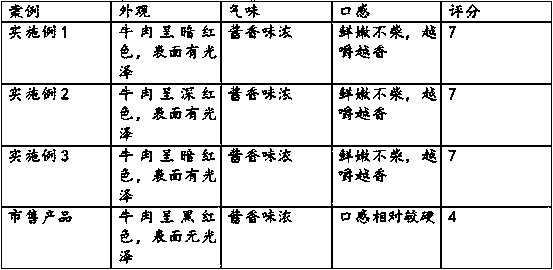

Examples

Embodiment 1

[0027] This embodiment provides a kind of method for quickly making stewed beef with sauce, comprising the following steps:

[0028] (1) Select 20 kilograms of beef, trim excess fat and sundries, wash and cut into pieces of about 250 grams each, soak in clean water for 15 minutes, and then store at 4°C for later use.

[0029] (2) Saute the spices until fragrant, then sieve 100 meshes after superfine grinding, take 400 grams of sieved spice powder and add 4 kg of ethanol aqueous solution with a mass concentration of 5% at 55°C and ultrasonic power of 300 W. Extract under the condition of frequency 40 kHz for 20 minutes to obtain spice liquid.

[0030] (3) Pour 1.5kg of vegetable oil into the pot first. After the oil is 80% hot, add 2kg of seasoning and sauté until fragrant. Then add 4kg of spice liquid and 20kg of drinking water. Use high heat and normal pressure to boil. After boiling, switch to low heat Boil for 25 minutes to obtain stewed soup, cool and filter, and store at...

Embodiment 2

[0041] This embodiment provides a kind of method for quickly making stewed beef with sauce, comprising the following steps:

[0042] (1) Select 20 kilograms of beef, trim excess fat and sundries, wash and cut into pieces of meat about 250 grams each, soak in water for 20 minutes, and then store at 4°C for later use.

[0043] (2) Stir-fry the spices until fragrant, sieve 100 meshes after ultrafine grinding, take 400 grams of sieved spice powder and add 4 kg of ethanol aqueous solution with a mass concentration of 10% at 50 ° C, ultrasonic power 400 W, ultrasonic The extraction was carried out for 20 minutes at a frequency of 35 kHz to obtain a spice liquid.

[0044] (3) Pour 1.5kg of vegetable oil into the pot first. After the oil is 80% hot, add 2kg of seasonings and sauté until fragrant. Then add 4kg of spice liquid and 20kg of drinking water. Use high heat and normal pressure to cook. After boiling, switch to low heat Boil for 30 minutes to obtain stewed soup, cool and filt...

Embodiment 3

[0055] This embodiment provides a kind of method for quickly making stewed beef with sauce, comprising the following steps:

[0056] (1) Select 20 kilograms of beef, trim excess fat and sundries, wash and cut into pieces of about 250 grams each, soak in clean water for 30 minutes, and then store at 4°C for later use.

[0057] (2) Stir-fry the spices until fragrant, sieve 100 meshes after superfine grinding, take 400 grams of sieved spice powder and add 4 kg of ethanol aqueous solution with a mass concentration of 10% at 60 ° C, ultrasonic power 200 W, ultrasonic The extraction was carried out for 30 minutes at a frequency of 30 kHz to obtain a spice liquid.

[0058] (3) Pour 1.5kg of vegetable oil into the pot first. After the oil is 80% hot, add 2kg of seasoning and sauté until fragrant. Then add 4kg of spice liquid and 20kg of drinking water. Use high heat and normal pressure to boil. After boiling, switch to low heat Boil for 30 minutes to obtain stewed soup, cool and filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com