Copper-containing hazardous waste treatment process

A treatment process and hazardous waste technology, which is applied in the field of copper-containing hazardous waste treatment process, can solve the problems of not considering the specificity of copper-containing waste, differentiated treatment of hazardous waste, and incomplete treatment, so as to achieve stable output and achieve compliance The effect of high emission and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

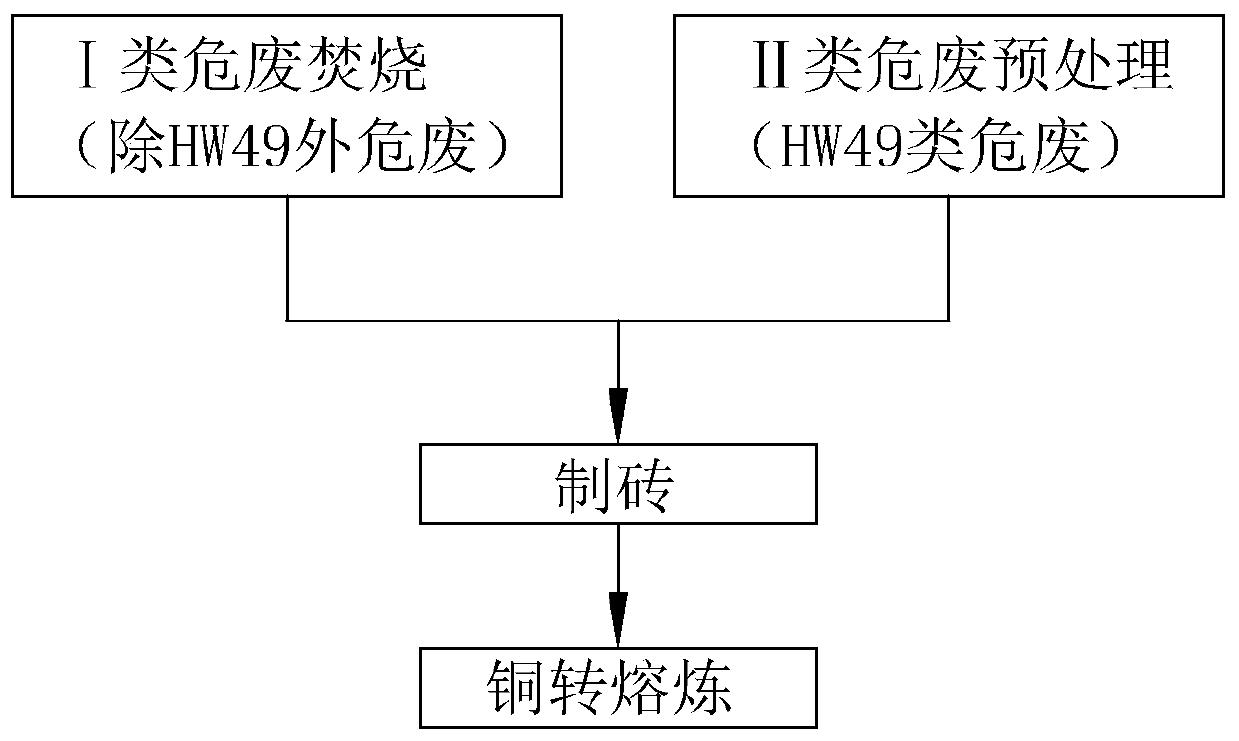

[0054] refer to figure 1 , is a copper-containing hazardous waste treatment process disclosed in the present invention, including Class I hazardous waste incineration, Class II hazardous waste pretreatment, brick making, copper brick smelting and flue gas treatment.

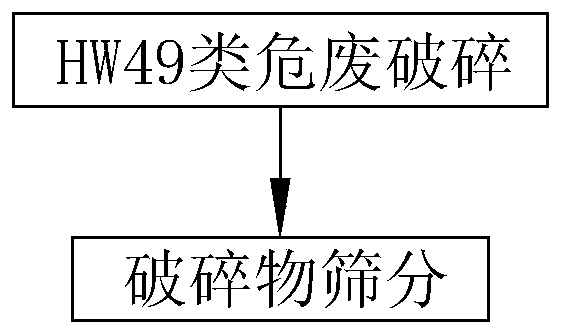

[0055] Among them, Class I hazardous waste refers to other hazardous wastes except HW49, such as HW12 dye, paint waste, HW17 surface treatment, HW22 copper-containing waste, HW45 organic halide-containing waste, HW46 nickel-containing waste, HW48 non-ferrous metal smelting waste , HW50 waste catalyst, etc. Class II hazardous waste refers to HW49 hazardous waste, and the common one is waste circuit boards.

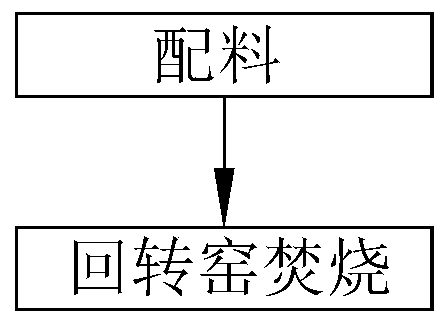

[0056] refer to figure 2 , Class I hazardous waste incineration includes two steps of batching and incineration, specifically: use purchased copper-containing general solid waste, at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com