Sand mold casting process by means of retractable core bar

A technology of sand casting and core bone, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of deterioration of the production environment, cold cracking, sawdust or foam board big odor, etc., to achieve a good production environment, improve Concession, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

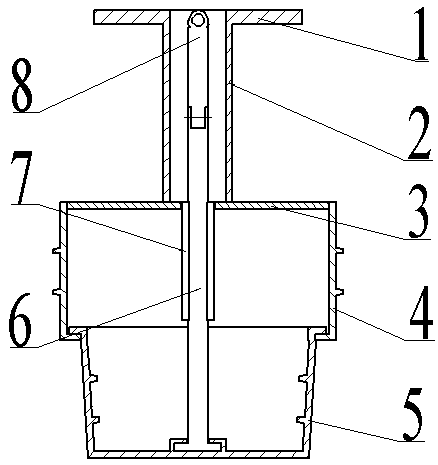

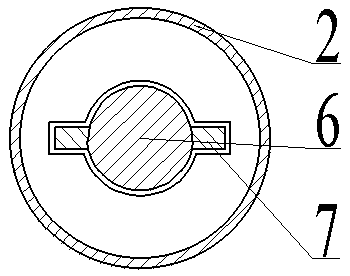

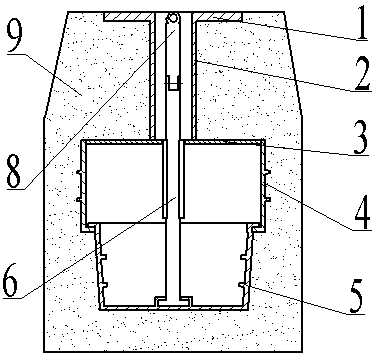

[0021] Specific examples: such as figure 1 with figure 2 As shown, the telescopic mandrel used in the present invention includes a steel pipe 2, a steel rod 1, an upper casing 4, a lower casing 5, a sliding rod 6 and a lifting rod 8, the steel rod 1 is welded on one end of the steel pipe 2, and the upper casing 4 is a hollow cylinder with an opening at the bottom, and its top is a detachable cover plate 3. The cover plate 3 of the upper shell 4 is connected to the end of the steel pipe 2 without a steel rod, and there is a round hole in the center of the connecting part of the cover plate 3 and the steel pipe 2. , the lower shell 5 is a hollow cylinder, and the upper and lower shells can be prisms or cylinders according to the requirements of the casting. Air outlet holes are arranged on the wall of the lower shell, and the inner wall of the bottom opening end of the upper shell 4 and the lower shell There is a flange on the outer wall of the top of the body 5, reinforcing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com