Preparation method of diamond rope saw bead string based on metal powder extrusion molding

A diamond wire saw and diamond bead technology, applied in metal processing equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve problems affecting the cutting speed and service life of diamond wire saws, uneven distribution of matrix alloys and diamond particles, problems such as low production efficiency, to achieve the effect of high production efficiency, stable quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing diamond wire saw beads based on metal powder extrusion molding, comprising the following steps:

[0034] Step A, dry-mix metal pre-alloy powder and diamond particles to obtain matrix alloy powder, heat and knead the matrix alloy powder and high-viscosity water-based binder, and then granulate to form matrix alloy for extrusion feeding;

[0035] Step B, extruding and molding the carcass alloy into a carcass alloy tube;

[0036] Step C, cutting the carcass alloy round tube into a ring blank to obtain a diamond beaded ring blank;

[0037] Step D, degreasing and drying the diamond beaded ring blank by soaking in water;

[0038] Step E, putting an iron core support in the diamond beaded ring blank processed in step D, the diamond beaded ring blank covers the iron core support, and then vacuum thermal degreasing and vacuum pressurization Sintering to make diamond wire saw beads.

[0039] Put the iron core support body in the diamond beaded ring blan...

Embodiment 1~5

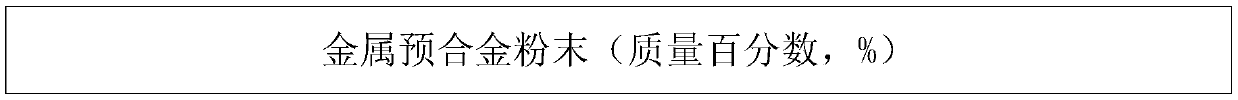

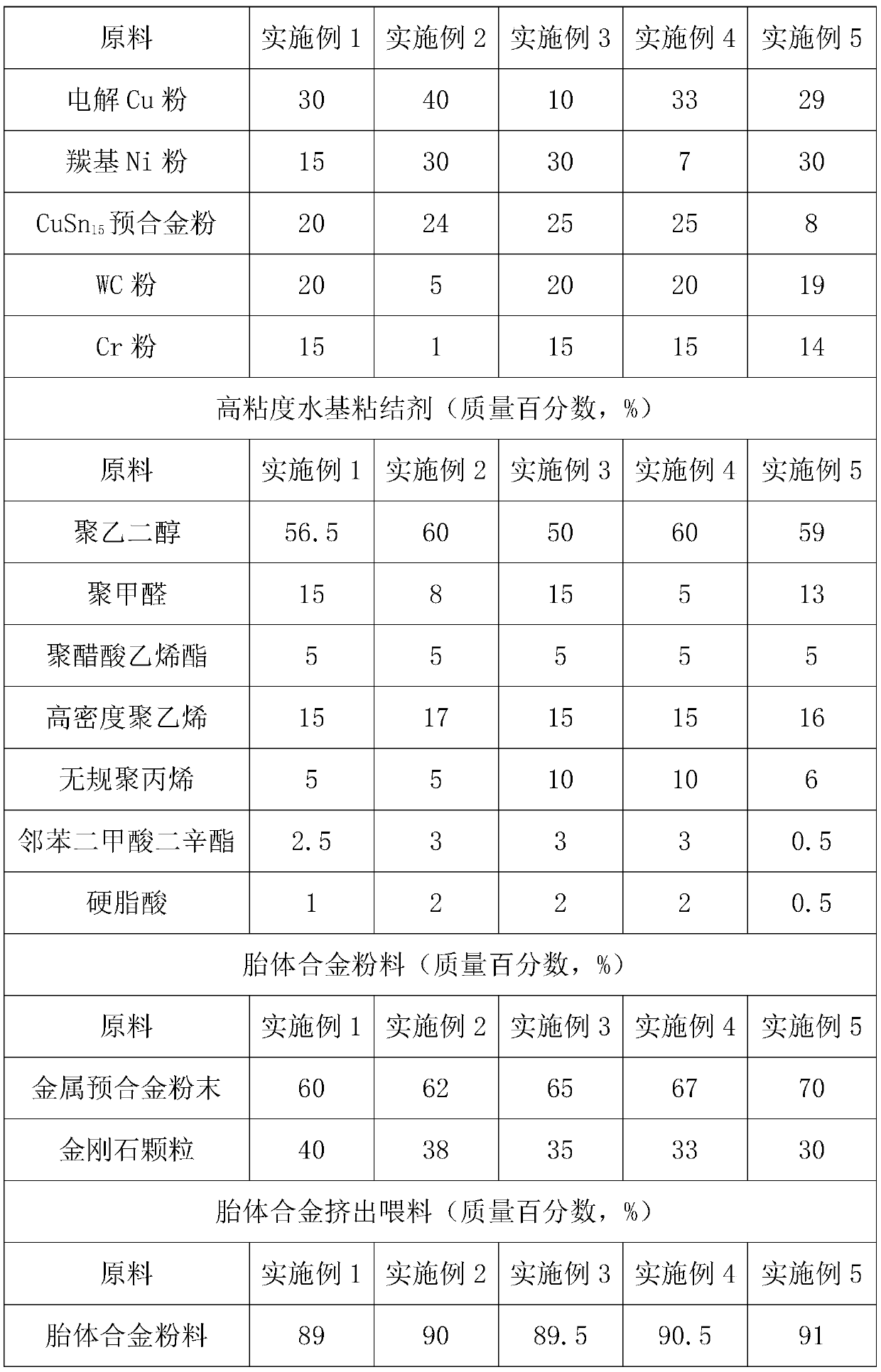

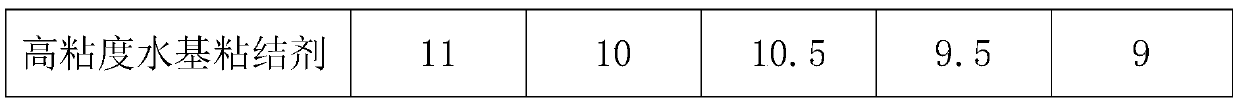

[0077] Examples 1-5 Weigh each raw material according to Table 1, wherein the electrolytic Cu powder and CuSn 15 The particle size of the pre-alloyed powder is 500 mesh, the particle size of the carbonyl Ni powder, WC powder and Cr powder are respectively 2 / g;

[0078] The particle size classification of the diamond particles is as follows: 35-40 mesh accounts for 30%, 40-45 mesh accounts for 30%, 45-50 mesh accounts for 20% and 50-60 mesh accounts for 20%.

[0079] And Examples 1-5 prepare diamond wire saw beads extruded from metal powder according to the following steps, and the beaded products are subjected to conventional surface treatment and then connected to the steel wire rope to obtain a diamond wire saw:

[0080] Table 1- Raw material composition of diamond wire saw beads

[0081]

[0082]

[0083]

[0084] Step A, preparation of carcass alloy extrusion feed

[0085] Step A1, weighing the metal pre-alloyed powder and diamond particles according to Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com