Winding machine with feeding function

A winding machine and functional technology, applied in the field of winding machines with feeding function, can solve the problems of inconvenient discharge, low production efficiency, unfavorable market competitiveness, etc., to save time, improve efficiency, and facilitate feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

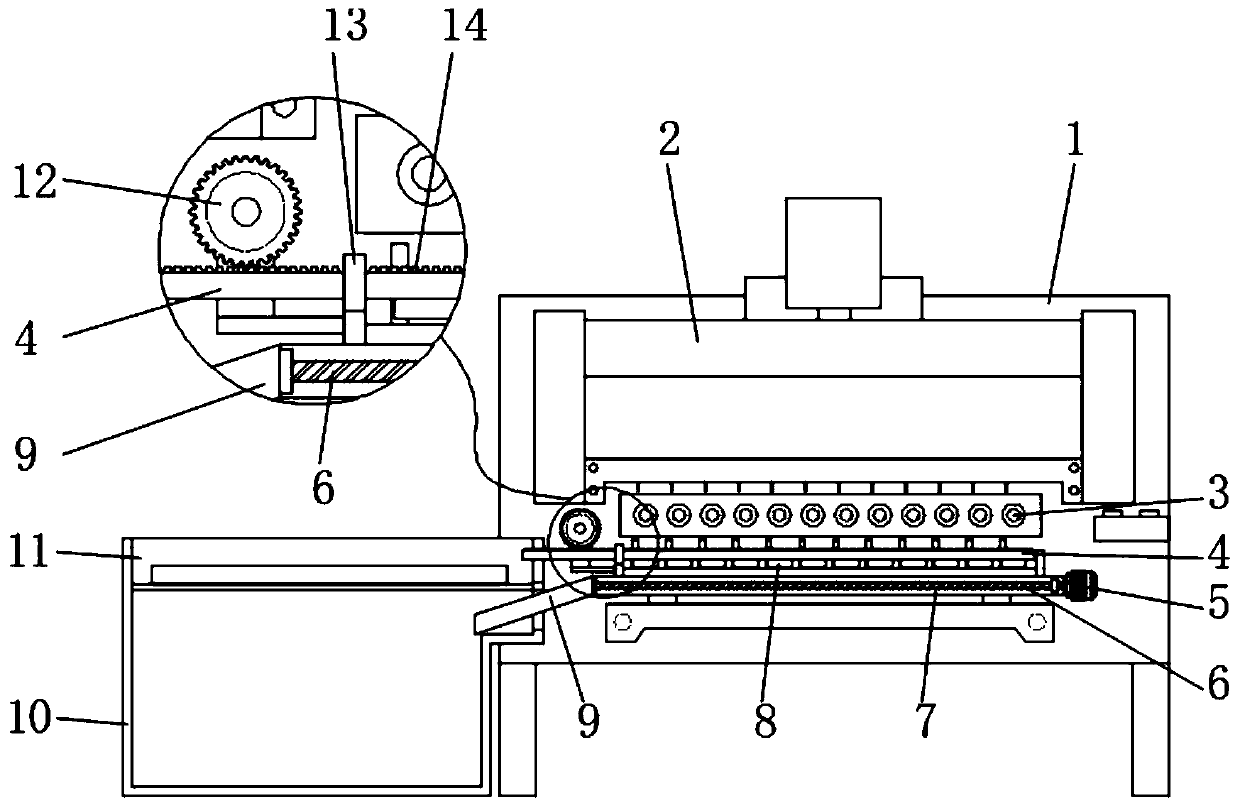

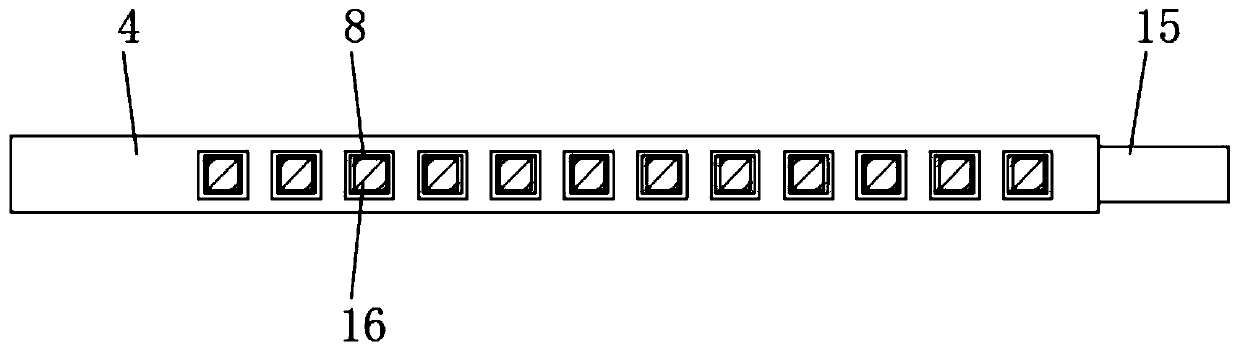

Embodiment 1

[0030] Embodiment one, with reference to Figure 1-3 , a winding machine with a feeding function, comprising a winding machine body 1, a winding frame 2 is arranged on the front surface of the winding machine body 1, and a plurality of winding shafts 3 are installed rotating below the winding frame 2, The bottom of the winding shaft 3 is provided with an unloading frame 7, and one side surface of the unloading frame 7 is provided with a discharge channel 18, and one side of the discharge channel 18 is located at the edge of the surface of the discharge frame 7 and is equidistantly provided with a plurality of feeding Groove 17, and the top of a plurality of feeding troughs 17 is set up with loading rack 4, and one end of unloading rack 7 is welded with baffle plate, and the surface of baffle plate is welded with sleeve column 15, and one end of sleeve column 15 is inserted and installed in the feeding Inside the rack 4, the other end of the unloading rack 7 is welded with a sl...

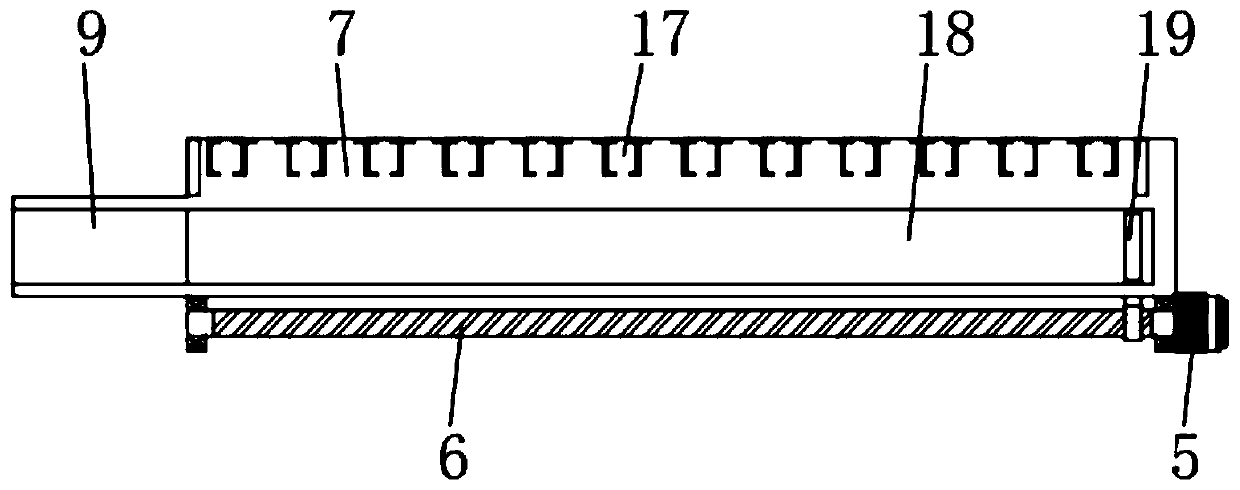

Embodiment 2

[0031] Embodiment two, refer to figure 1 , image 3 and Figure 5A discharge motor 5 is installed on the side of the unloading frame 7, and the output end of the discharge motor 5 is connected to a screw mandrel 6 in rotation, and one end of the screw mandrel 6 is fixedly connected with the side of the unloading frame 7 through a bearing seat, and the screw mandrel 6 The surface of the surface is threadedly connected with a threaded sleeve 22, and one end of the threaded sleeve 22 is welded with a connecting rod, and one end of the connecting rod runs through the unloading rack 7 and is fixedly connected with a scraper 19, and the scraper 19 is in the discharge channel 18 of the unloading rack 7 Inside, a control panel is installed on the surface of the winding machine body 1, and the output end of the control panel is electrically connected to the discharge motor 5, and one side of the screw rod 6 is located on the side of the unloading frame 7, and a strip-shaped relief slo...

Embodiment 3

[0032] Embodiment three, refer to figure 1 and Figure 4 , the top surface of the material box 10 is located on both sides of the suction channel 11, and there are material guide chambers 20, and the bottom surface of the material guide chamber 20 is an inclined slope, and the inner walls of the two material guide chambers 20 pass through the suction channel 11 A through groove 21 with a rectangular structure is provided. The inside of the feed box 10 is located below the material suction channel 11 and is provided with a collection cavity. The side wall surface of the feed box 10 is provided with a rectangular slot corresponding to the collection cavity. Corresponding to the material plate 9, one end of the material discharge plate 9 extends through the rectangular groove into the material collection chamber of the material box 10, the material discharge plate 9 is placed obliquely with respect to the unloading frame 7, and the material discharge plate 9 welded obliquely is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com