Oligomer prepared from superfine blast furnace slag powder and preparation method thereof

A technology of blast furnace slag powder and blast furnace slag, which is applied in the field of oligomers prepared from ultrafine blast furnace slag powder and its preparation field, can solve the problems of poor mutual solubility and cohesion of inert materials, poor fluidity, etc., and achieve improved road bearing capacity, high resistance The effect of low pressure and pressure bleeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

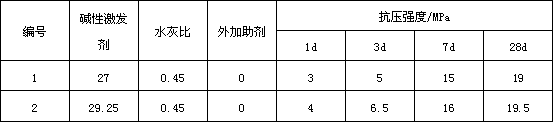

Embodiment 1

[0023] An oligomer prepared by using superfine blast furnace slag powder, including the following raw materials, component A: 700 kg of blast furnace slag, 300 kg of fly ash; 450 kg in total of component B: 27 kg of alkaline activator, plus 6.75 kg of auxiliary agent I, 0.135 kg of external auxiliary agent II, and 0 kg of external auxiliary agent III; the weight ratio of component A and component B is 1:0.45; 416.115 kg of water.

[0024] The alkaline activator is MgoH, the external additive I is calcium formate, the external additive II is triethanolamine, and the external additive III is sodium metasilicate, the modulus is 1.4, and the solid content is 0.41.

[0025] The method for preparing above-mentioned oligomer is:

[0026] Step 1), weigh component A by weight, put the weighed component A into the θ3.2*13m ball mill, the diameter-to-length ratio of the grinder is required to be greater than 4, and grind to obtain D50 10μm, specific surface area greater than 700m 2 / k...

Embodiment 2

[0029] An oligomer prepared by utilizing superfine blast furnace slag powder, including the following raw materials in kilograms by weight, component A: 700 kilograms of blast furnace slag, 300 kilograms of fly ash; 450 kilograms of component B: 29.25 kilograms of alkaline activator, 9 kg of additives I, 0.225 kg of additives II, and 0 kg of additives III; the weight ratio of components A and B is 1:0.45; water is 411.525 kg.

[0030] The alkaline activator is MgoH, the external additive I is calcium formate, the external additive II is triethanolamine, and the external additive III is sodium metasilicate, the modulus is 1.4, and the solid content is 0.41.

[0031] The method for preparing above-mentioned oligomer is:

[0032] Step 1), weigh component A by weight, put the weighed component A into the ball mill, the diameter-to-length ratio of the grinder is required to be greater than 4, and the specific surface area obtained by grinding is greater than 700m 2 / kg of composit...

Embodiment 3

[0035] An oligomer prepared by utilizing superfine blast furnace slag powder, including the following raw materials in kilograms by weight, component A: 700 kilograms of blast furnace slag, 300 kilograms of fly ash; 450 kilograms of component B: 29.25 kilograms of alkaline activator, 9 kg of additives I, 0.225 kg of additives II, and 54 kg of additives III; the weight ratio of components A and B is 1:0.45; 357.525 kg of water.

[0036] The alkaline activator is MgoH, the external additive I is calcium formate, the external additive II is triethanolamine, and the external additive III is sodium metasilicate, the modulus is 1.4, and the solid content is 0.41.

[0037] The method for preparing above-mentioned oligomer is:

[0038] Step 1), weigh component A by weight, put the weighed component A into a ball mill, and grind to obtain a specific surface area greater than 700m 2 / kg of composite powder;

[0039] Step 2), weigh component B according to the weight ratio, add it to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com