Bead point oil as well as preparation method and construction process thereof

A construction technique and bead point technology, which is applied in the field of bead point oil and its preparation, can solve problems such as uneven bead point, uneven coating film, and poor adhesion, and achieve low price, continuous and uniform coating film, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

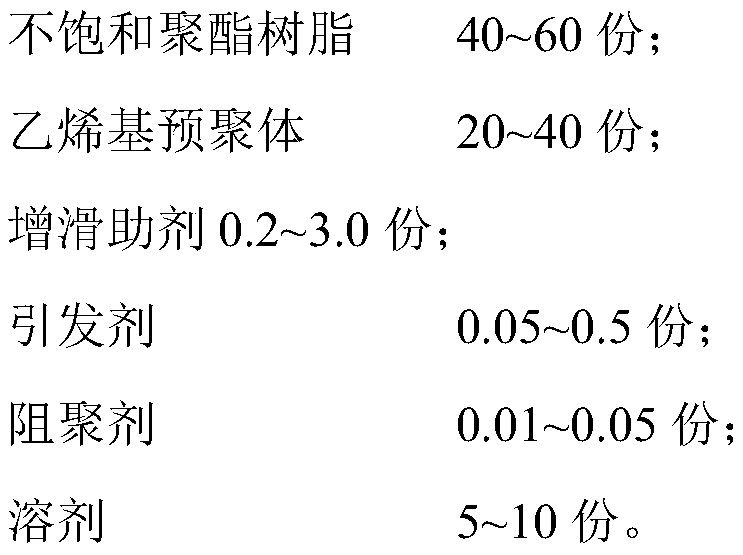

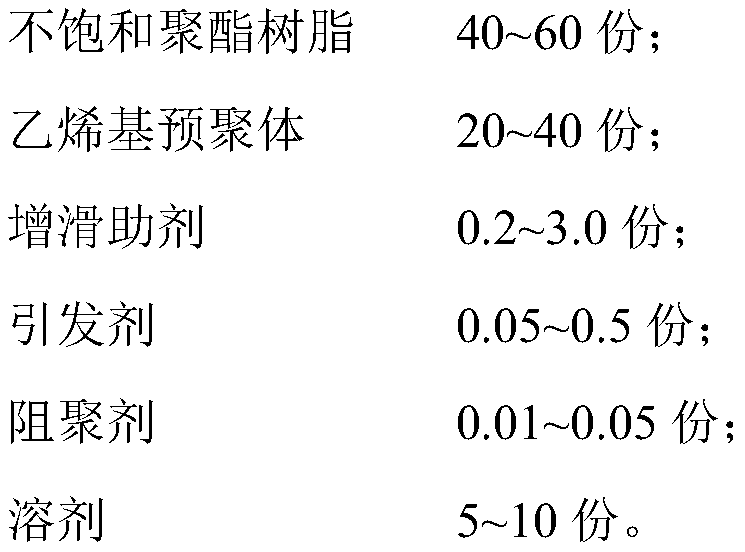

[0039] The preparation method of the unsaturated polyester resin described in the present invention comprises the following steps: according to parts by weight, 10-20 parts of ethylene glycol, 5-10 parts of methyl propylene glycol, 10-20 parts of neopentyl glycol, cis-butene 5-20 parts of dianhydride, 0.5-5 parts of 3,6-endomethylene tetrahydrophthalic anhydride (CAS No.: 129-64-6), 0.5 parts of sebacic acid (CAS No.: 111-20-6) ~10 parts, 20~30 parts of phthalic acid, 10~20 parts of ethanol, put them into the reaction kettle, turn on the vertical condensate water, then raise the temperature to the water outlet of the condenser tube, control the temperature of the distillation head at 100~110°C, and then raise the temperature to 210°C ~230°C, keep warm for 1~5h, and filter to obtain the unsaturated polyester resin.

[0040] In a preferred embodiment, the preparation method of the unsaturated polyester resin comprises the following steps: according to parts by weight, 15 parts o...

Embodiment 1

[0068] This embodiment provides a kind of bead point oil, according to parts by weight, the raw material components of said bead point oil include: 45 parts of unsaturated polyester resin, 25 parts of vinyl prepolymer, 1 part of slipping aid, initiator 0.1 part, 0.02 part of polymerization inhibitor, 6 parts of solvent.

[0069] The preparation method of the unsaturated polyester resin comprises the following steps: according to parts by weight, 15 parts of ethylene glycol, 7 parts of methyl propylene glycol, 15 parts of neopentyl glycol, 13 parts of maleic anhydride, 3,6- Put 2.5 parts of endomethylenetetrahydrophthalic anhydride, 5.3 parts of sebacic acid, 25 parts of phthalic acid, and 15 parts of ethanol into the reaction kettle, turn on the vertical condensate water, then raise the temperature until the water comes out of the condenser tube, and control the distillation head The temperature is 105°C, then raised to 220°C, kept for 2 hours, and filtered to obtain the unsat...

Embodiment 2

[0072] This embodiment provides a kind of bead point oil, according to parts by weight, the raw material composition of described bead point oil comprises: 55 parts of unsaturated polyester resin, 35 parts of vinyl prepolymer, 2 parts of slipping aid, initiator 0.3 parts, 0.04 parts of polymerization inhibitor, and 8 parts of solvent.

[0073] The preparation method of the unsaturated polyester resin comprises the following steps: according to parts by weight, 15 parts of ethylene glycol, 7 parts of methyl propylene glycol, 15 parts of neopentyl glycol, 13 parts of maleic anhydride, 3,6- Put 2.5 parts of endomethylenetetrahydrophthalic anhydride, 5.3 parts of sebacic acid, 25 parts of phthalic acid, and 15 parts of ethanol into the reaction kettle, turn on the vertical condensate water, then raise the temperature until the water comes out of the condenser tube, and control the distillation head The temperature is 105°C, then raised to 220°C, kept for 2 hours, and filtered to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com