High-hardness coating material for aluminum alloy protection and preparation method and application thereof

A coating material and high-hardness technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of high brittleness of the coating, the hardness cannot meet the requirements of scratch resistance, and the limitation of the use field. The effect of improved flexibility, improved protection, good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

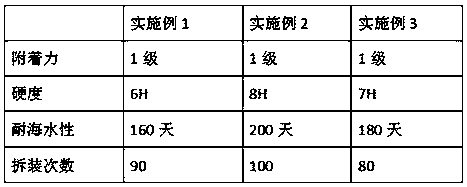

Embodiment 1

[0024] This embodiment provides a high-hardness coating material for surface protection of aluminum alloy substrates, which is prepared by the following steps:

[0025] (1) Under microwave conditions, add 50 g of dimethyl carbonate diluent and 10 g of nano-SiO to a four-necked flask 2 Sol, add 15g of 2,4-toluene diisocyanate (TDI) with stirring at room temperature, raise the temperature to 80°C, slowly add 20g of dehydrated polypropylene glycol 1000 (PPG-1000) dropwise within 0.5h, react for 2h, drop Add 5.0g of perfluorophenol and continue the reaction for 2h to form prepolymer I.

[0026] (2) Cool down the temperature of prepolymer I to 50°C, then add 20g of 2,2-dimethylolpropionic acid (DMPA) required for the experiment according to the content of water-based groups, and then quickly raise the temperature to 80°C for 2 hours to form a polymer II.

[0027] (3) Cool down the temperature of the polymer II to 50°C, then add 5g of acid red B according to the amount of free -NC...

Embodiment 2

[0031]This embodiment provides a high-hardness coating material for surface protection of aluminum alloy substrates, which is prepared by the following steps:

[0032] (1) Under microwave conditions, add 100g of dimethyl carbonate and 10g of nano-SiO to a four-necked flask 2 Sol, add 15g of 2,4-toluene diisocyanate (TDI) with stirring at room temperature, raise the temperature to 80°C, slowly add 20g of dehydrated polypropylene glycol 1000 (PPG-1000) dropwise within 0.5h, react for 2h, drop Add 5.0g of perfluorophenol and continue the reaction for 2h to form prepolymer I.

[0033] (2) Cool down the temperature of the prepolymer I to 50°C, then add 25g of 2,2-dimethylolpropionic acid (DMPA) required for the experiment according to the water-based group content, and then rapidly raise the temperature to 80°C for 2 hours to form a polymer II.

[0034] (3) Cool polymer II to 50°C, then add 10g of acid red B according to the amount of free -NCO remaining in the reaction system, r...

Embodiment 3

[0038] This embodiment provides a high-hardness coating material for surface protection of aluminum alloy substrates, which is prepared by the following steps:

[0039] (1) Under microwave conditions, add 60g of diluent ethanol and 10g of nano-SiO to a four-neck flask 2 Sol, add 15g of 2,4-toluene diisocyanate (TDI) with stirring at room temperature, raise the temperature to 80°C, slowly add 20g of dehydrated polypropylene glycol 1000 (PPG-1000) dropwise within 0.5h, react for 2h, drop Add 5.0g of perfluorophenol and continue the reaction for 2h to form prepolymer I.

[0040] (2) Cool down the temperature of the prepolymer I to 50°C, then add 36g of 2,2-dimethylolpropionic acid (DMPA) required for the experiment according to the water-based group content, and then rapidly raise the temperature to 80°C for 2 hours to form a polymer II.

[0041] (3) Cool down the temperature of the polymer II to 50°C, then add 20g of acid red B according to the amount of free -NCO remaining in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com