Dry-process slag granulation system

A slag and granulation technology, which is applied in the field of dry slag granulation system, can solve the problems of waste of water resources, waste of heat energy resources, and insufficient use of high-temperature slag heat, so as to reduce waste, save water resources, and improve heat recovery efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

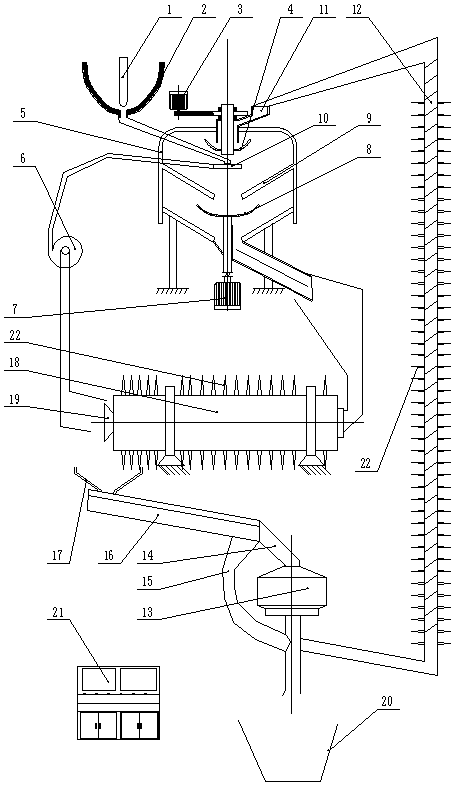

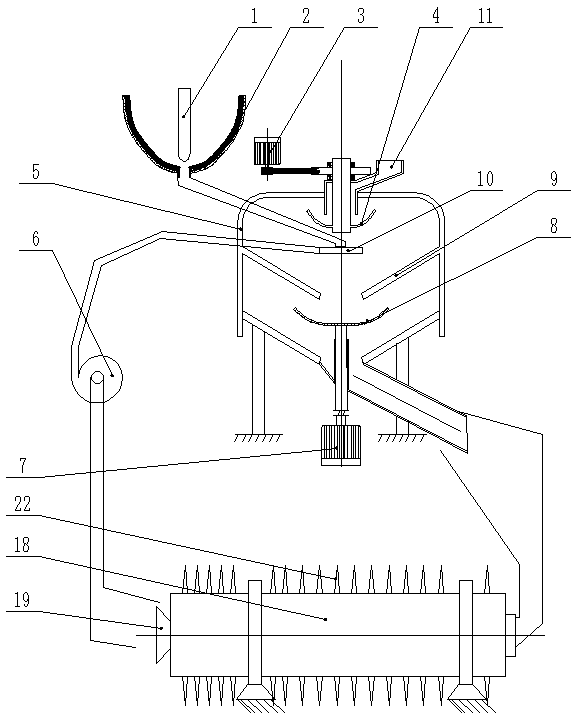

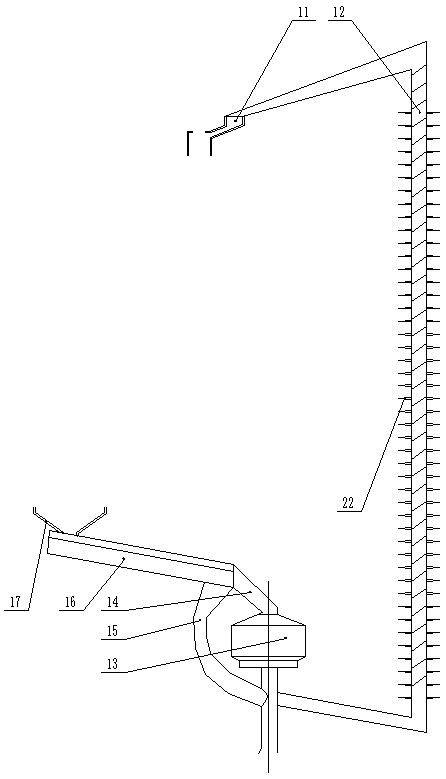

[0022] Embodiment: the structure of the present invention is as Figure 1 to Figure 3 As shown, in the specific working process, the heat recovery structure in the agglomeration part and the granulation part in the present invention is an integral low-temperature heat recovery system, which is specifically realized by the following structure: the agglomeration part includes slag bag 2, slag agglomeration Tank 5, cold slag distributing pan 4, annular turbulent flow granulation nozzle 10, the slag agglomeration tank 5 is installed on the ground through a frame, the slag bag 2 is arranged on the top of the slag agglomeration tank 5, and passed through The pipeline extends into the inside of the slag agglomeration tank 5, and the slag bag 2 is fed through the feeding stopper 1; the annular turbulent granulation nozzle 10 is provided with a blower fan 6; The top of the central axis of the block tank 5 is driven by the cold slag distribution motor 3, and the cold slag feeding port 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com