A repeatedly bending asphalt block processing device

A processing device and asphalt block technology, applied in the field of asphalt, can solve the problems of peeling off the surface of asphalt blocks, the decline in the quality of waste asphalt, troublesome manual processing, etc., and achieve the effects of wide application, expanding the degree and scope of bending, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

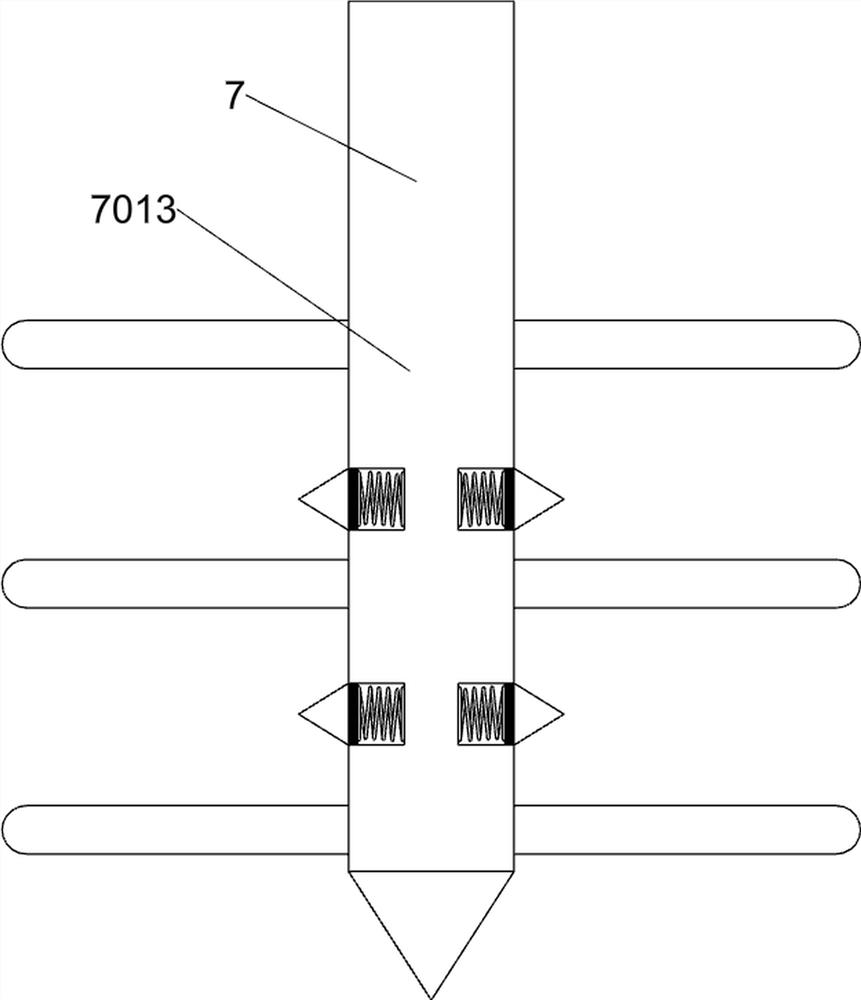

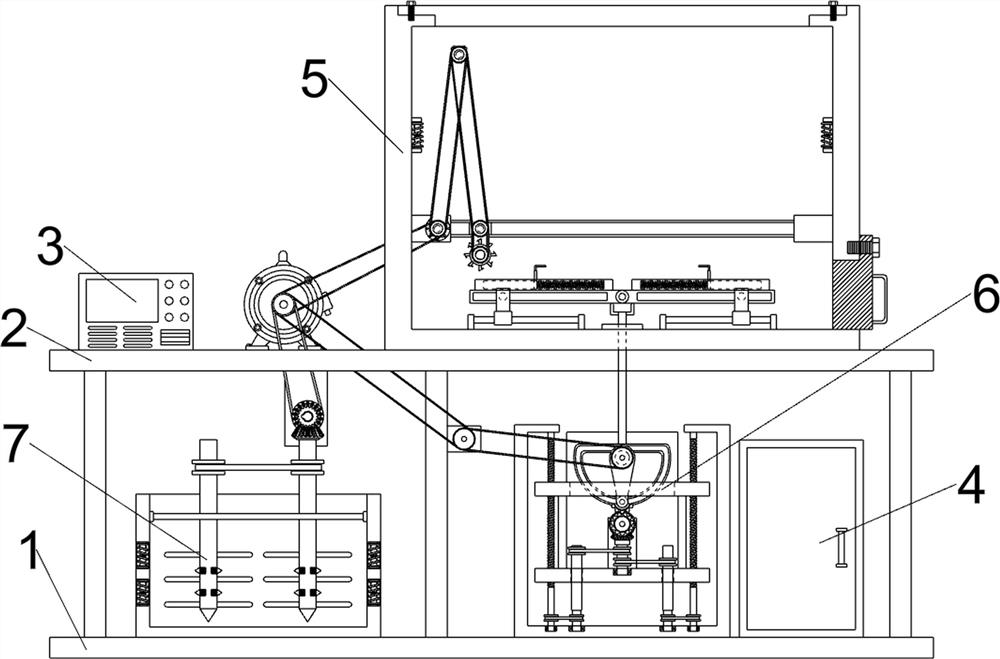

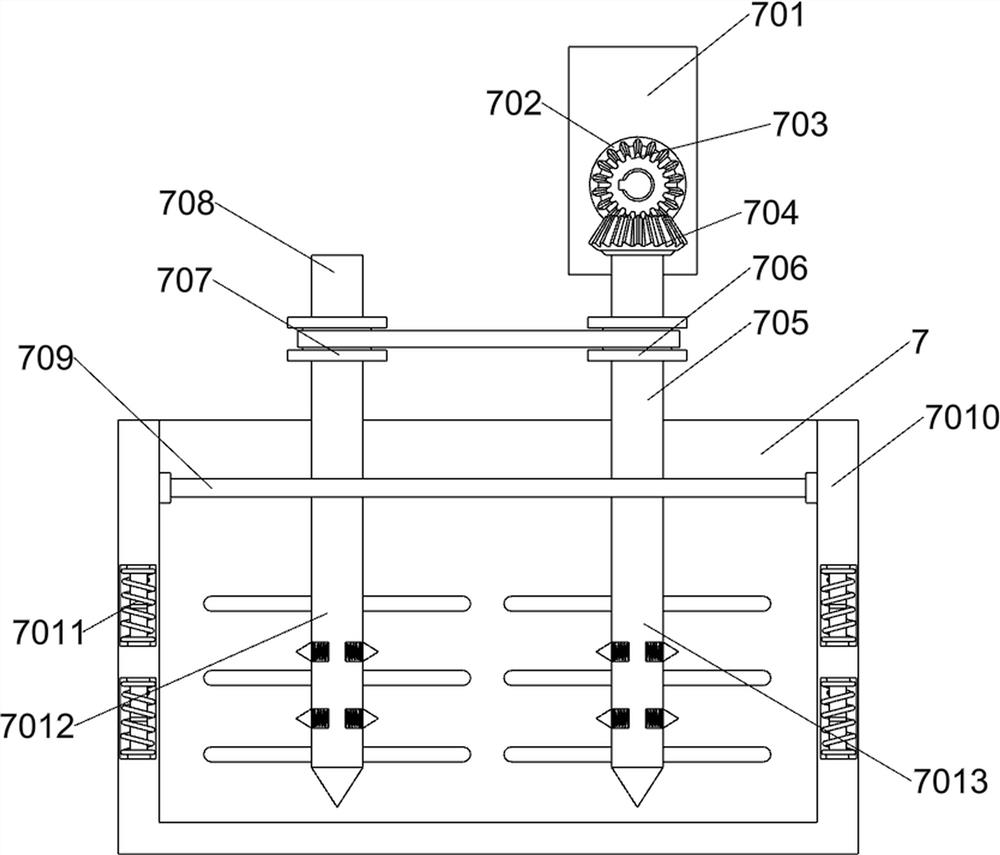

[0025] A repeatedly bending asphalt block processing device, such as Figure 1-5 As shown, it includes installation and connection base plate 1, machine tool plate 2, operation control panel 3, tool box 4, bending and separation system 5, top control system 6 and asphalt block heating and crushing system 7; installation and connection base plate 1; machine tool plate 2. The bottom of the machine tool board 2 is welded to the installation and connection base plate 1; the operation control panel 3 is connected to the machine tool board 2 under the operation control panel 3; the tool box 4 is bolted to the installation and connection base plate 1 under the tool box 4; Separation system 5, the lower part of the bending separation system 5 is connected with the machine tool board 2; the upper top control system 6, the lower part of the upper top control system 6 is connected with the installation connection base plate 1, and the upper part of the upper top control system 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com