Skin-friendly soft nonwoven fabric

A non-woven, soft technology, used in non-woven fabrics, textiles and papermaking, one-component polyolefin rayon, etc., can solve skin allergies, prone to eczema and other problems, increase skin affinity, reduce skin Allergy, good breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

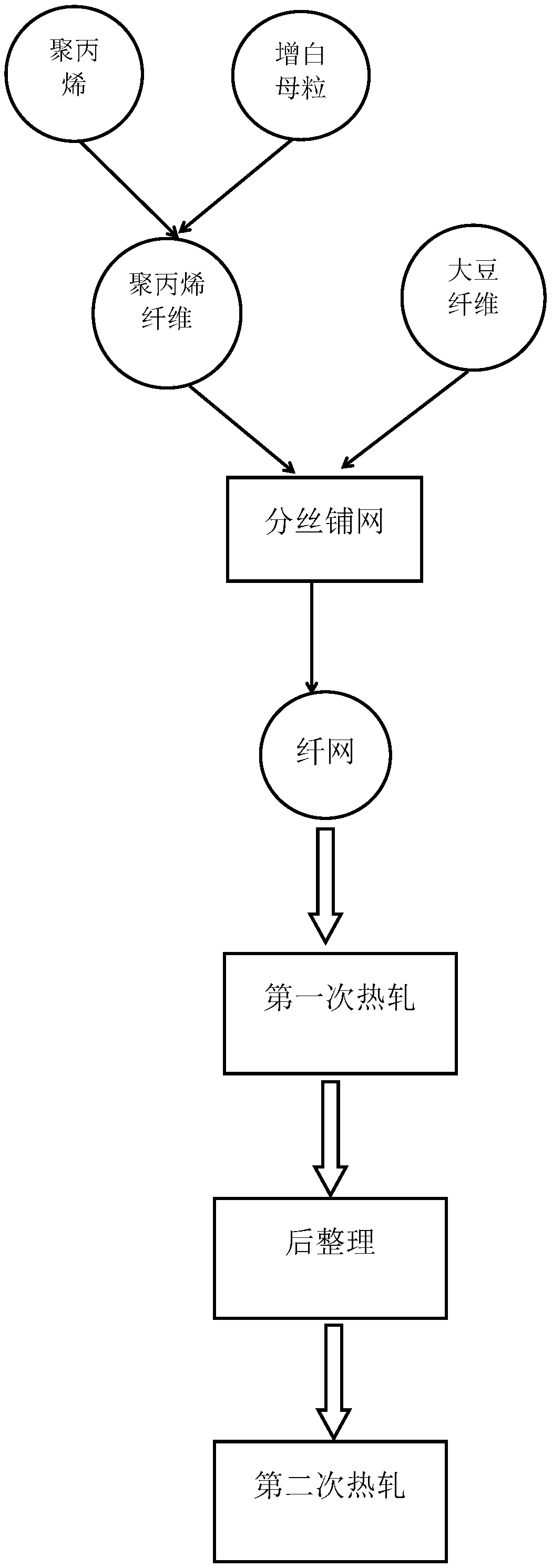

Method used

Image

Examples

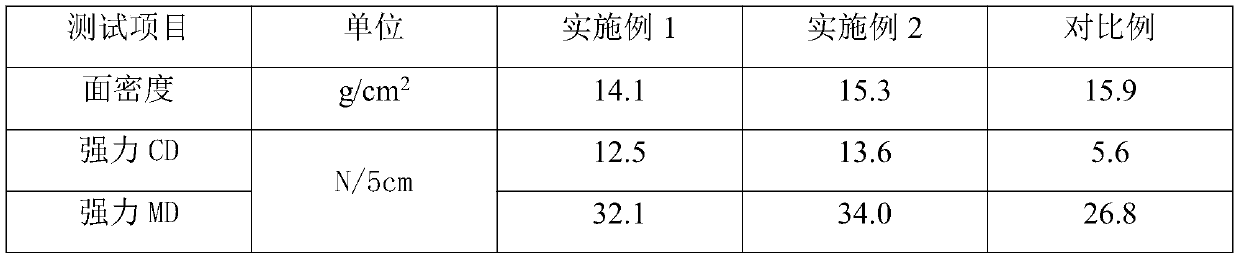

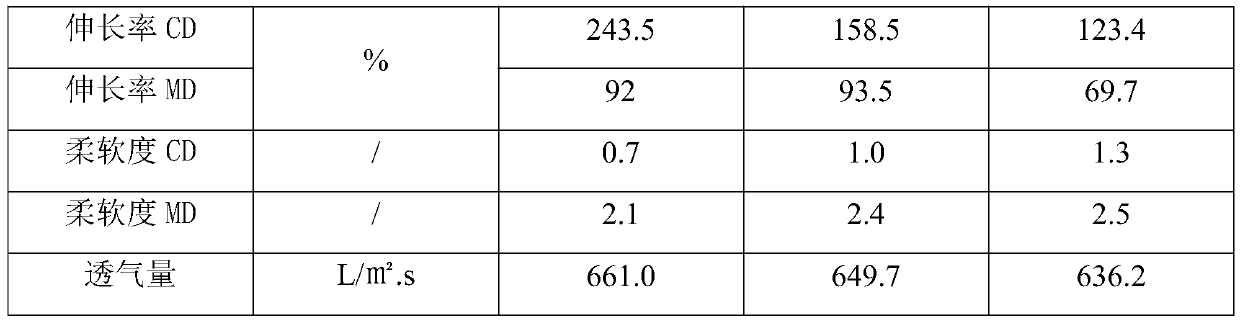

Embodiment 1

[0034] 1. Add 140KgPP granules, 50KgPOE elastomer granules and 10Kg whitening masterbatch into the hopper; vacuum pump the mixed and stirred raw materials to the screw through the feeding system for extrusion and melting. The melting temperature of the screw is 180°C to obtain a hot melt ; Filtration, metering and distribution of the hot melt at 230° C., 5 MPa. The hot melt spinning that has been distributed and metered is to spray the silk through the 0.3mm aperture, and cool it through the cooling bellows. The temperature of the cooling bellows is 10°C, and the cooling wind speed is 0.2m / s. The filaments are separated by airflow, and the primary growth filaments are drawn by airflow through the bell mouth of the slit drafter. The airflow drafting speed is 2000m / H, and the fiber with a denier of 1.8 is obtained.

[0035] 2. The obtained polypropylene fiber is divided into wires and laid into a net. In this process, the gas produced by the air compressor pump is passed into th...

Embodiment 2

[0040] 1. Add 137KgPP granules, 59KgPOE elastomer granules and 4Kg whitening masterbatch into the hopper; vacuum pump the mixed and stirred raw materials to the screw through the feeding system for extrusion and melting. The melting temperature of the screw is 180℃~270℃ to obtain Hot melt; filter, measure and distribute the hot melt at 250°C and 10MPa. The hot melt spinning that has been distributed and metered is to spray out the silk through the 0.8mm aperture, and cool it through the cooling bellows. The temperature of the cooling bellows is 20°C, and the cooling wind speed is 1.5m / s. The filaments are divided by airflow, and the primary growth filaments are drawn by airflow through the bell mouth of the slit drafter. The airflow drafting speed is 5000m / H, and the fiber with a denier of 2.2 is obtained.

[0041]2. The obtained polypropylene fiber is divided into wires and laid into a net. In this process, the air compressor will generate gas into the trachea, and the 10.5Kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com