Shape memory alloy prestressed U-stirrup-FRP reinforced concrete beam and construction technology thereof

A memory alloy and concrete beam technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of low fiber strength utilization rate, limited increase in the bearing capacity of reinforced beams, and peeling of fiber cloth, so as to improve utilization rate and improve Shear and bending resistance, the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further explained below in conjunction with accompanying drawing and specific embodiment:

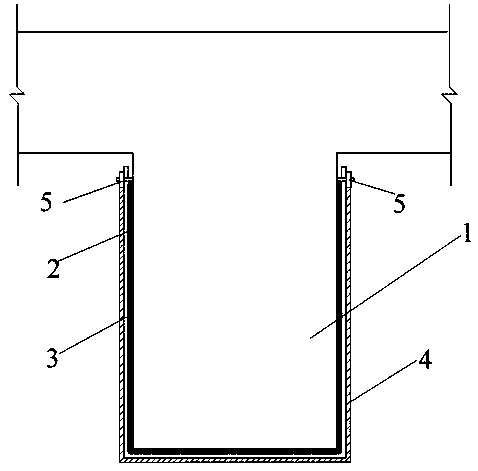

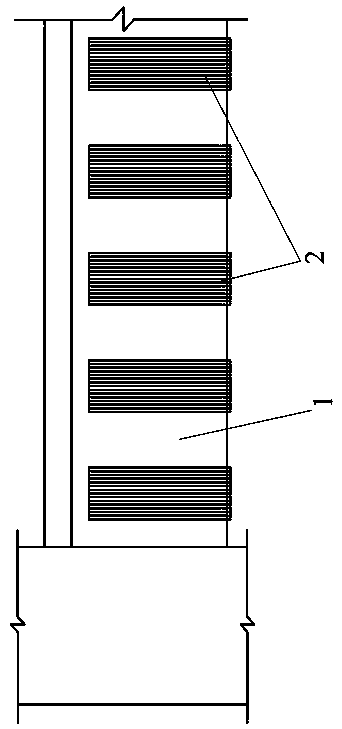

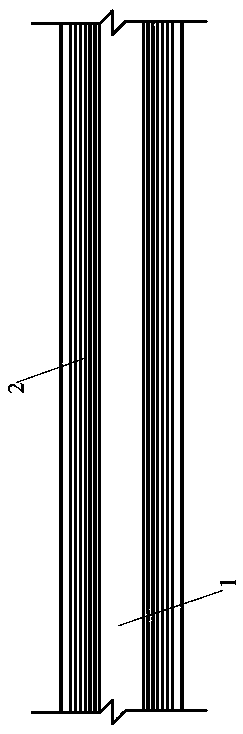

[0052] A shape memory alloy prestressed U-shaped hoop—FRP-reinforced concrete beam, including a concrete beam 1, external FRP 2, memory alloy prestressed U-shaped hoop 3, and externally coated sealing mortar 4; the external FRP 2 is pasted on the concrete by an adhesive The surface of the beam 1; the memory alloy prestressed U-shaped hoop 3 is arranged on the outside of the external FRP 2; the outer coating sealing mortar 4 is sealed and coated on the outer layer of the memory alloy prestressed U-shaped hoop 3 to reinforce and prevent the memory alloy prestressed U-shaped hoop 3 from being damaged corrosion. The concrete beam 1 is an ordinary concrete beam; the outer FRP 2 is cloth or plate, and the material is Fiber Reinforced Polymer; the material used for the memory alloy prestressed U-shaped hoop 3 is NiTiNb shape memory alloy; the outer coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com